PARTIAL PROTOTPYE

07: Clear Pocket

Use defaults provided by VCarve:

• Clear Pocket→Offset

• Cut Direction→Conventional

08: Ramp Plunge Moves

You don’t have to add ramp moves, but if you’d

like to make cleaner pocket cuts and put less

stress on your tooling, as discussed in “Ramp

Moves and Tabs” on page 155, check the Ramp

Plunge Moves box. Keep the default value of 1.0

inches in the Pocket Allowance box.

09: Save the toolpath name 000 Pocket 1.

10: Check all of your settings and select Calcu-

late.

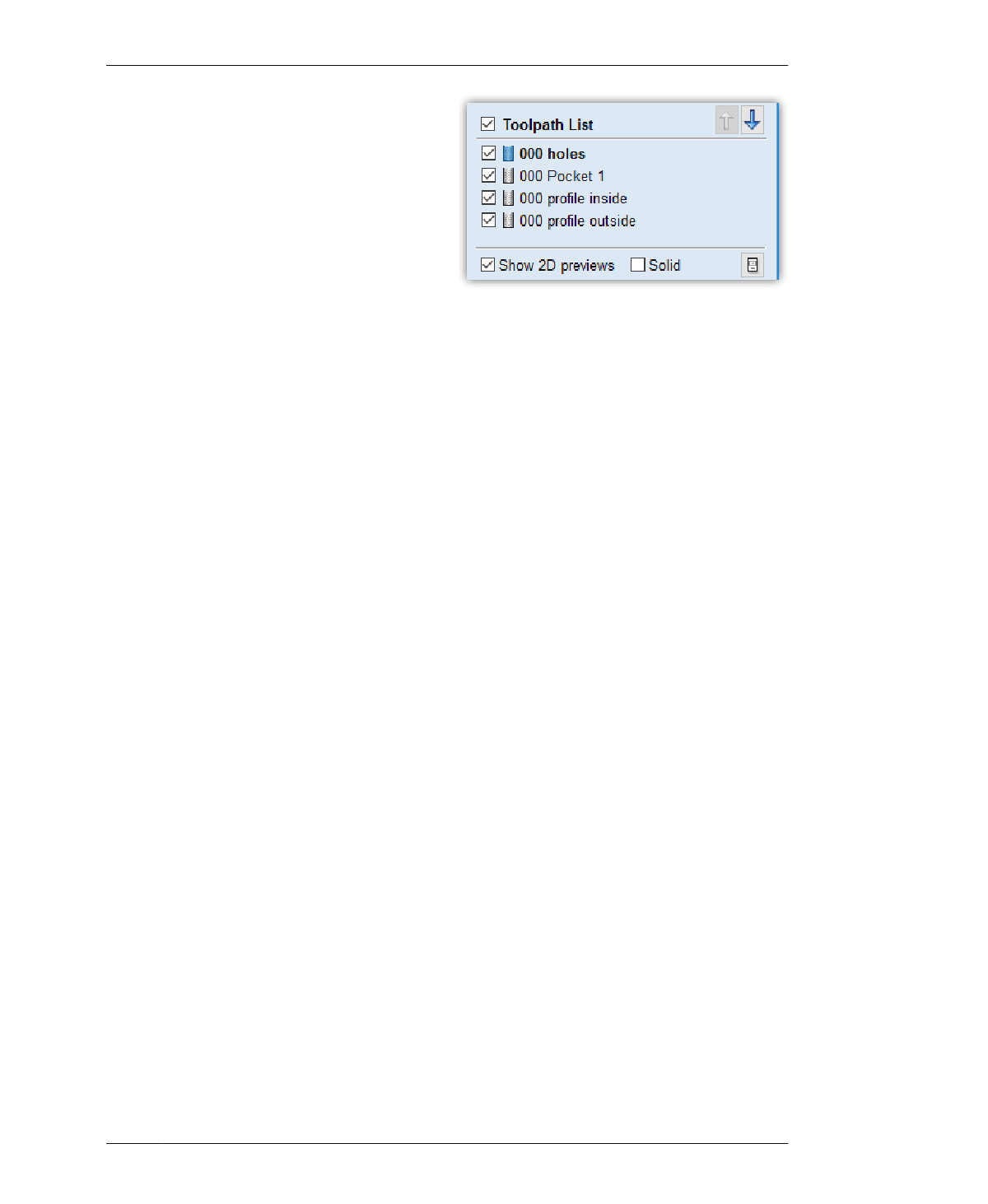

You should now have four toolpaths in your

toolpath list, 000 Pocket 1, 000 holes, 000 pro-

file inside, and 000 profile outside, as shown in

Figure 11-10.

SIMULATE

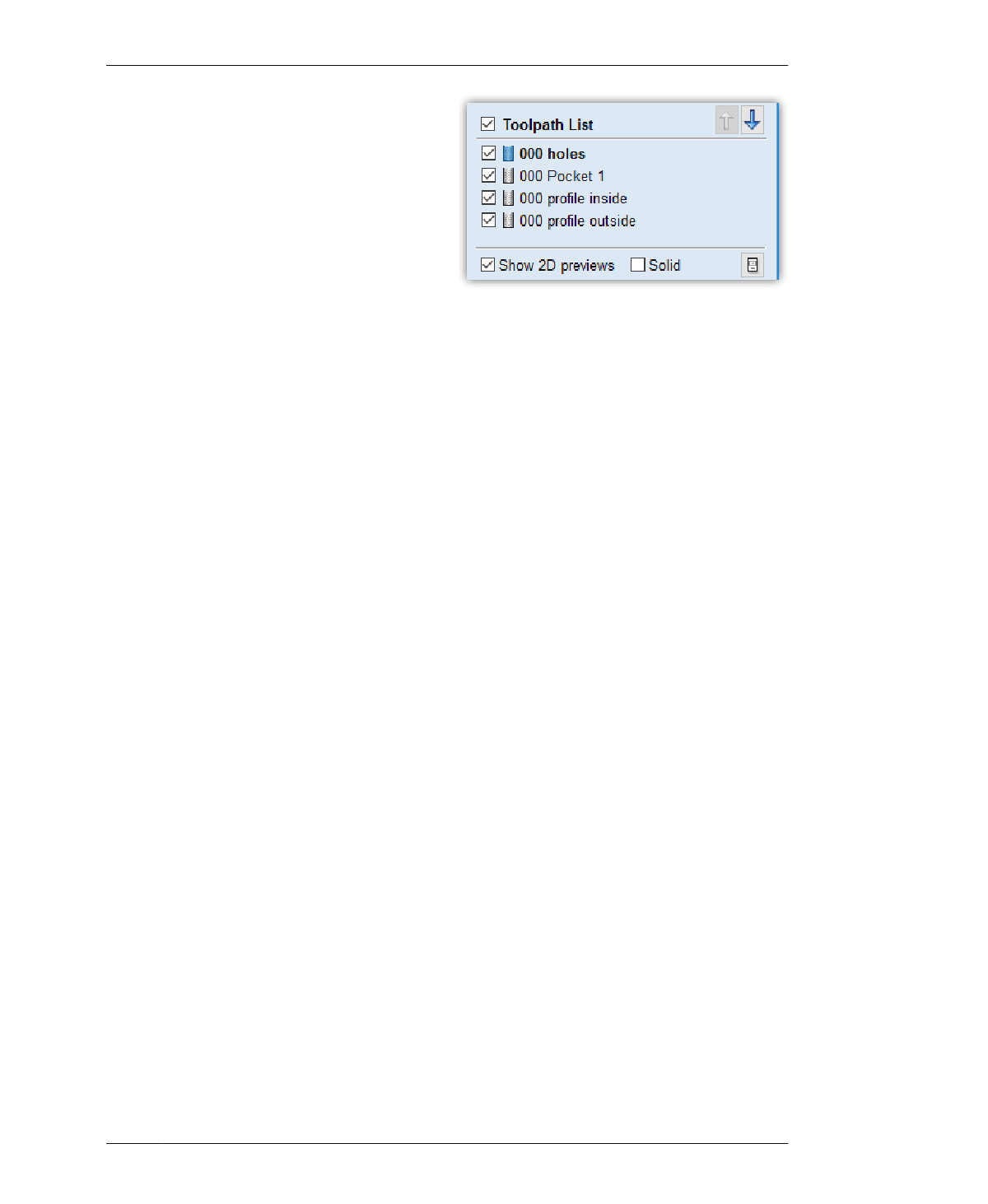

01: Move the holes toolpath to the first position

in the list. The holes use a smaller diameter

tool than the pockets and profile cuts.

CUT SEQUENCE FOR COMPLEX PARTS

Choreographing the toolpath sequence pre-

serves the alignment of smaller holes, slots, or

details, which are situated within larger parts

(see “Job Setup” on page 170). For similar rea-

sons, pocket cutting should also be handled on

an early pass, so pocketed details remain

aligned within the larger part.

Sequencing also comes into play when you’re

making complex three-dimensional parts, like

the Lounge Chair keys and their side pockets.

Following an exact sequence of cutting pockets

prior to inside profiles ensures that the end mill

the removes material in the right order. Reverse

the sequence of these toolpaths, and the three-

dimensional milled shape might vary.

02: Move the pocket toolpath to the second

position. You’ll want to cut the pockets before

making any through cuts that weaken the

material structure and cause vibration. Profile

inside is third on the list and profile outside

should be last.

03: As with the other toolpaths, review the ani-

mation and visuals of the vectors, spindle path,

as well as the actual pockets made by the ¼″

end mill. Ensure that the kerf removed

matches the end-mill size, that the tool creates

a pocket that is half the material thickness,

and that the pocket shapes match those in the

original cut file.

The Lounge Chair’s pocketing toolpath

removes four circular pockets from each of the

two side parts, and it forms four circular/donut

pockets to make the chair’s keys. Once the first

pocketing pass is made, the machine’s subse-

quent passes mill holes, inside cuts, and finally

profile cuts.

FIGURE 11-10

Set Toolpath Sequence

to cut holes first

11/90-MINUTE LOUNGE CHAIR

243