PARTIAL PROTOTPYE

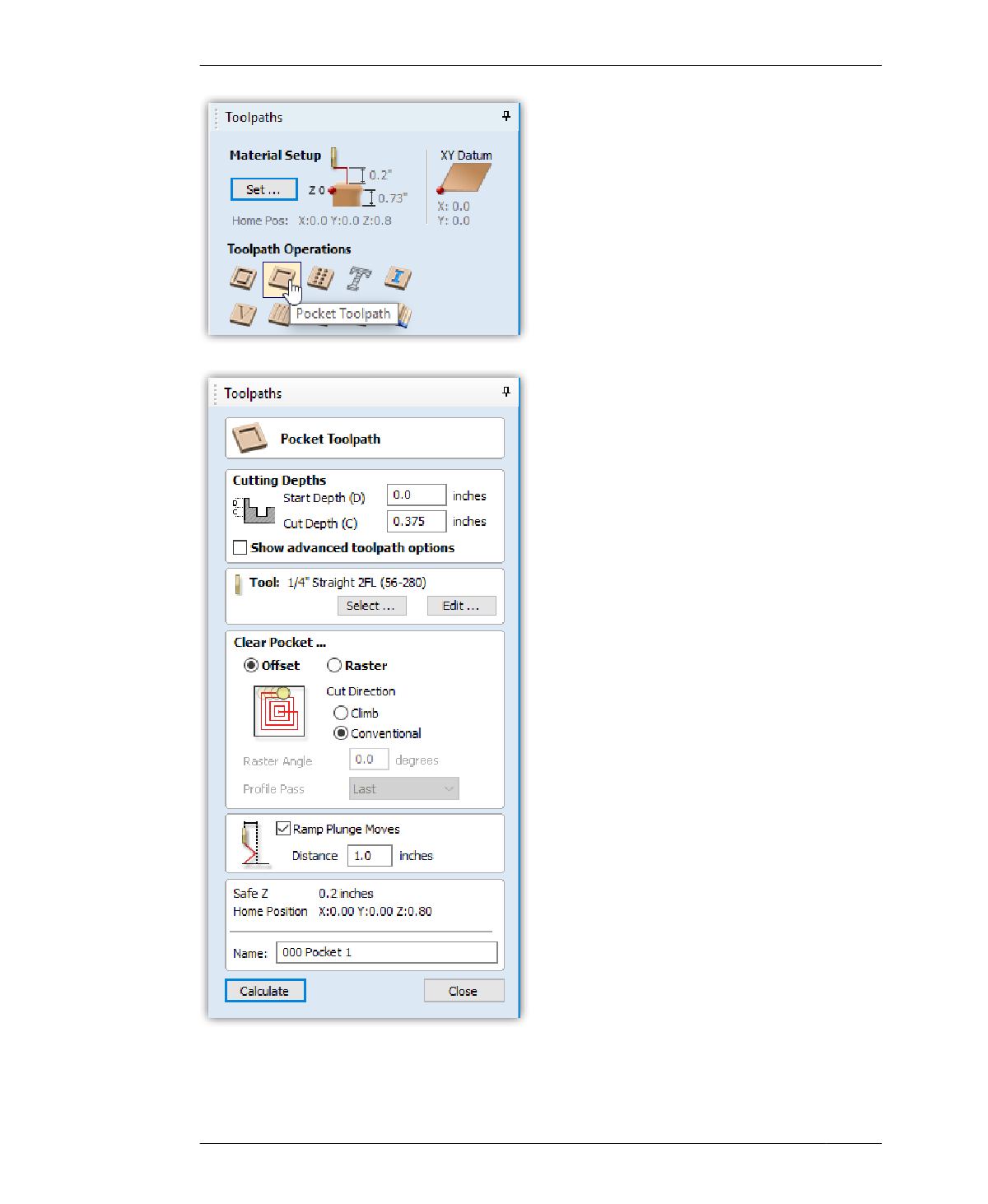

FIGURE 11-8

Select Pocket Toolpath

from the Toolpath

Operations menu

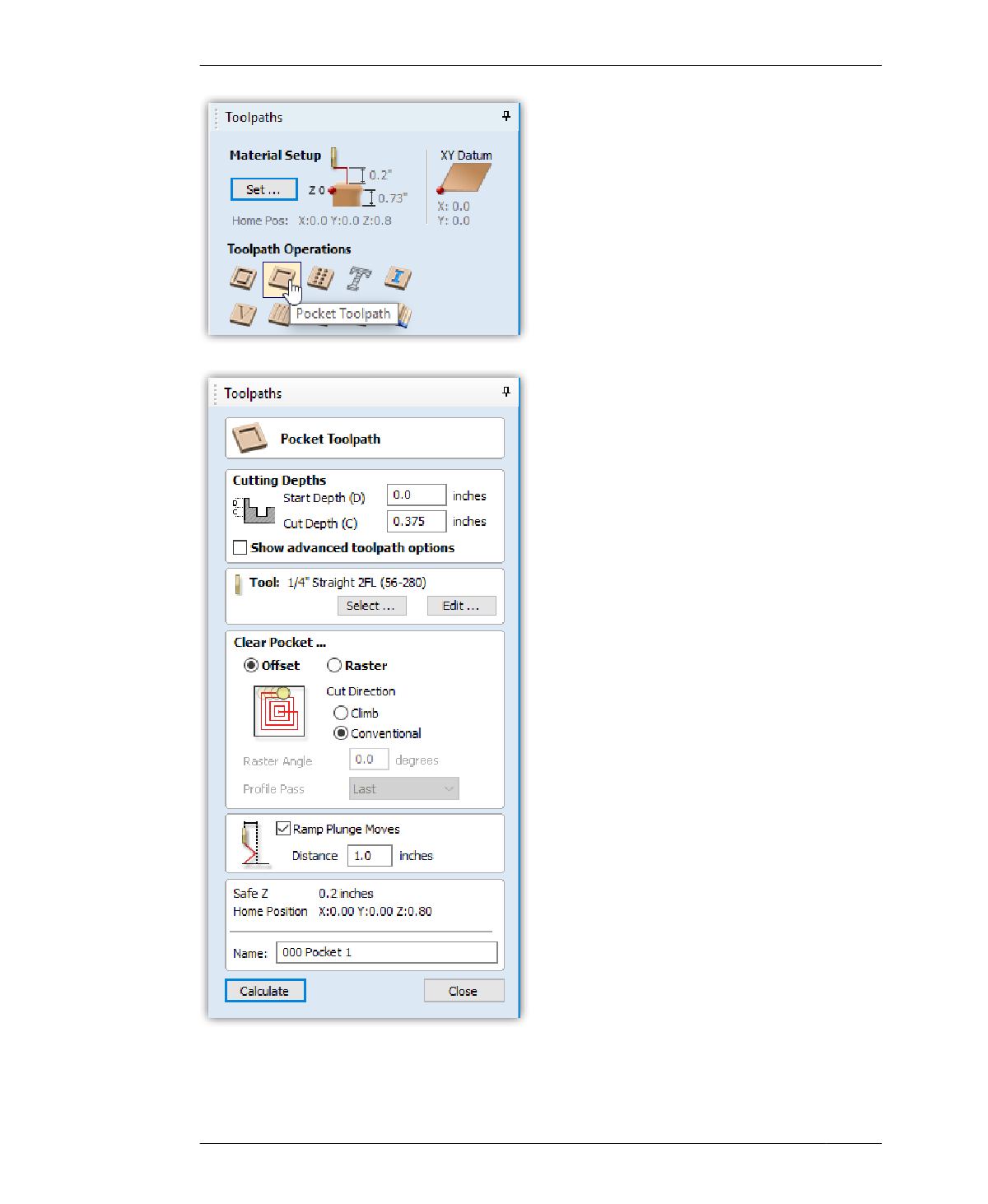

FIGURE 11-9

Set Cut Depth

242

DESIGN FOR CNC

elegant, flush inlay detail on each side of the

chair.

To achieve a flush fit, it’s critical to coordinate

your material thickness with the depth of all

pockets. Both the pocket cut depth and the

milling depth for the inlay keys must be half of

TMAX (in other words, TMAX/2), to get a flush

alignment.

CREATE POCKET TOOLPATHS

After programming the outside, inside, and

hole toolpaths, return to the main VCarve win-

dow.

01: Layers Menu

Turn off all layers, except the Pocket layer.

02: Toolpath Operations

Select the Pocket Toolpath icon, shown in

Figure 11-8, to open the pocketing settings

menu. Toolpaths menu → Pocket Toolpath. The

Pocket Toolpath menu will open.

03: Cutting Depths

Keep the Start Depth (D) at 0 and set the cut

depth (C) to half of TMAX (in our example, this

is 0.375”), shown in Figure 11-9.

04: Show Advanced Toolpath Options

Checking this box reveals the Use Vector Selec-

tion Order box. Check this box.

05: Tool

The pockets use the same ¼″ diameter end

mill as the inside and outside profile cuts, so

you can leave these settings unchanged.

06: Use Larger Area Clearance Tool

Sometimes it’s beneficial to use a larger diame-

ter tool to clear most of the material away

quickly and then clean up or cut fine details

with a smaller tool. Keep this option

unchecked; for our purposes, ¼″ diameter bit

is fine.