MEASURE & SCALE

MEASURE & SCALE

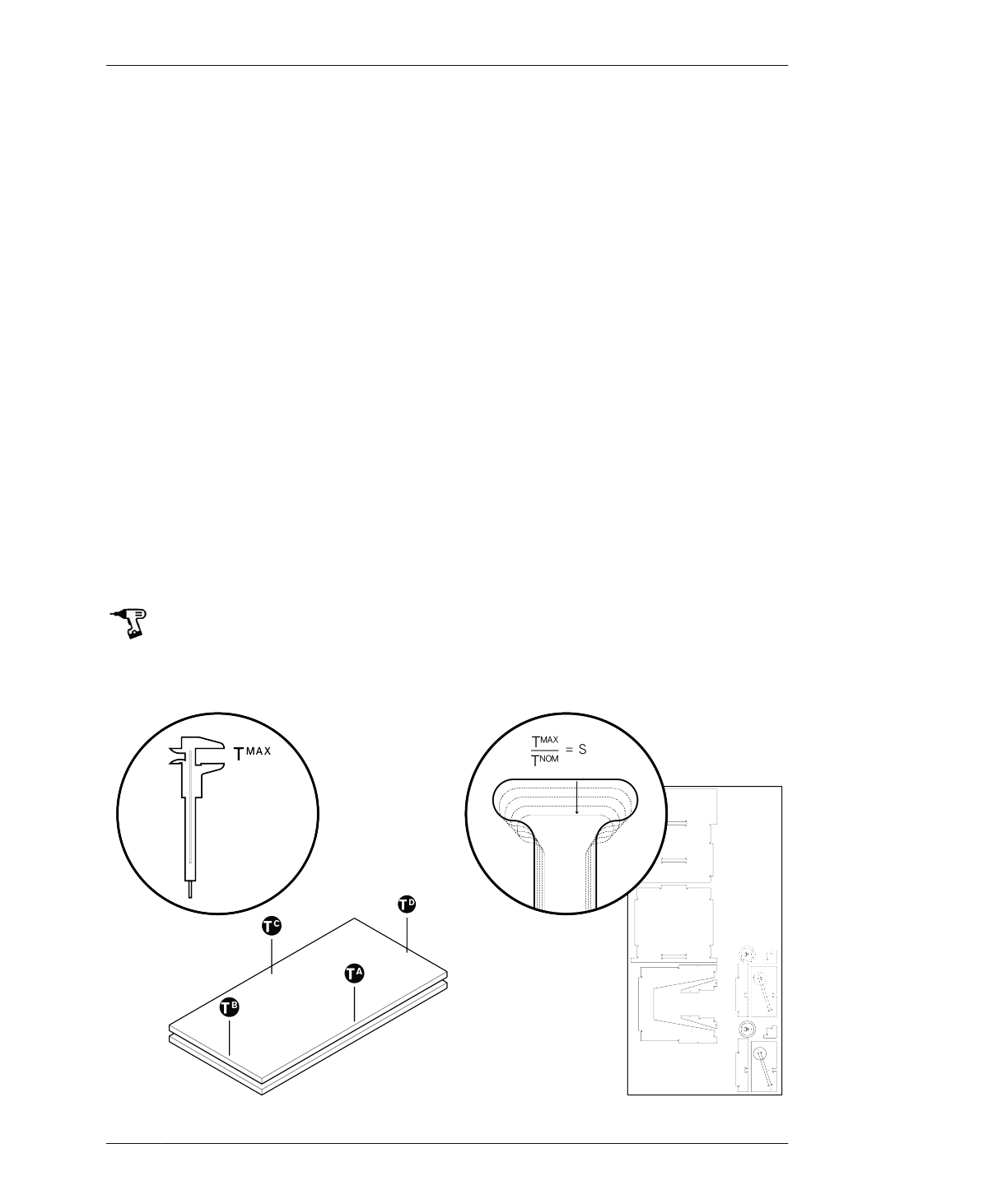

01: Review “Measure Your Materials” on page

132 and “Scale Your CAD File” on page 133 for

details on how to measure all of your sheets, as

illustrated in Figure 11-4.

02: Record TA, TB, TC, TD, and calculate TMAX,

your actual material thickness.

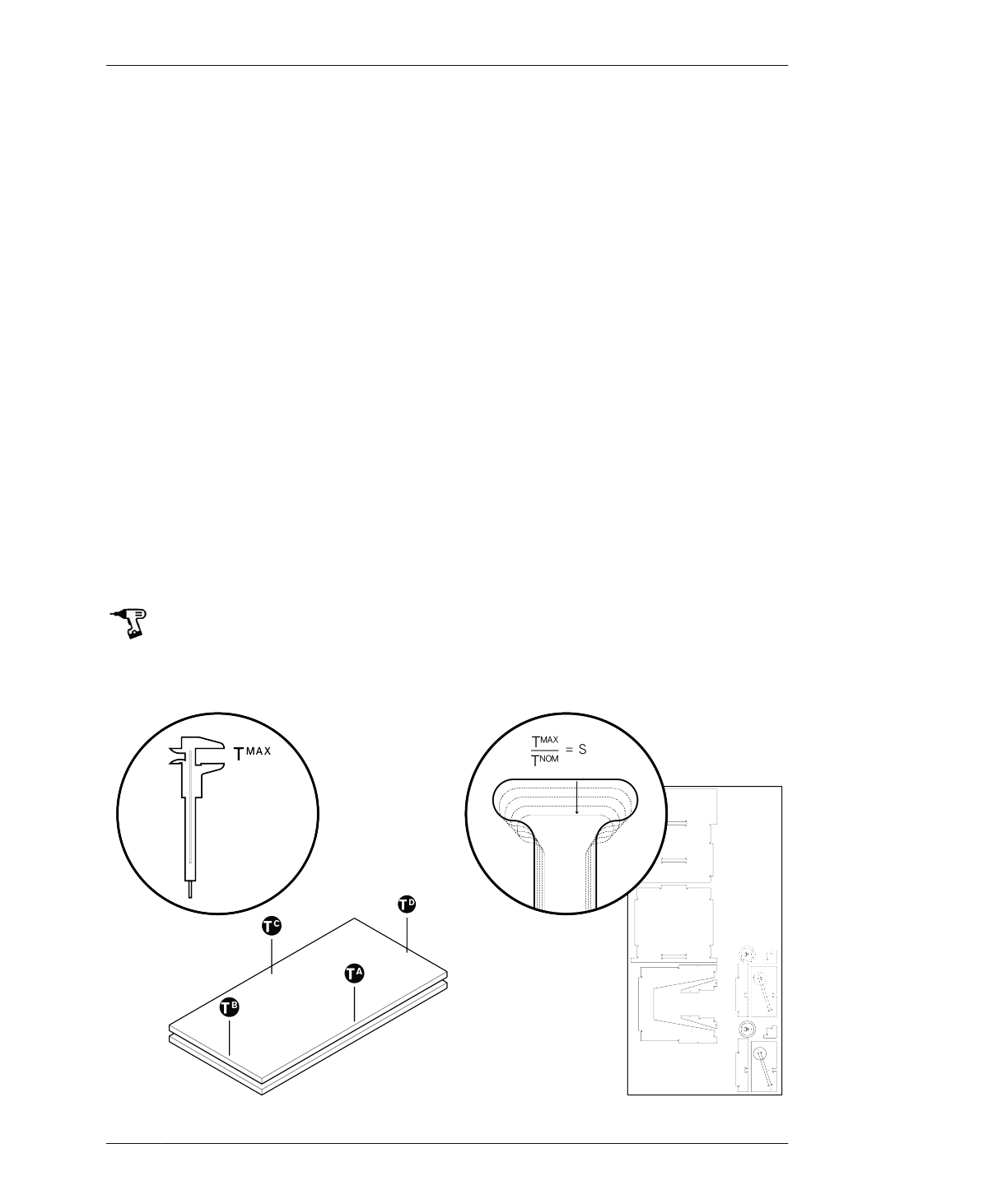

03: Divide TMAX by TNOM to calculate your file

scaling percentage (S).

04: Visit the book’s website (http://

www.designforcnc.com/) to download the 90-

Minute Lounge test piece

(AtFAB_LNG_TEST.skp) and the jig

(AtFAB_LNG_JIG.skp).

decrease the complexity and assembly time

of putting together the Lounge Chair. You can

nest jig parts into the cut file or cut them from

a scrap of material.

PARTIAL PROTOTPYE

Once you have procured and measured your

material, and after you have calculated your

scaling percentage, S, you’re ready to check

your fit with the test piece.

The 90-Minute Lounge Chair test piece parts in

AtFAB_LNG_TEST.skp simulate the chair’s join-

ery, as well as the fit of the hardware key and

pocket. A test piece that comes out success-

fully confirms that both CAD scaling and CAM

settings will work for the actual Lounge Chair.

05: Download the 90-Minute Lounge file

(AtFAB_LNG.skp) or use your modified file.

Open the lounge file in your CAD program.

The AtFAB_LNG_JIG.skp file contains parts for

a jig, which is extremely useful during assem-

bly. Although it’s not essential, using the jig

will save you lots of time and dramatically

01: Review “Test Pieces” on page 136 on the

concept and purpose behind full-scale proto-

types and test pieces. “Partial Prototyping:

Using a Test Piece” on page 212 walks you

through how to prepare, cut, and evaluate the

test piece.

FIGURE 11-4

Measure your material

and scale the CAD file

11/90-MINUTE LOUNGE CHAIR

239