DESIGN DECISIONS: 2D AND 3D MODIFICATIONS

materiality relative to modifications, details,

and proportions. Refer to Appendix B on how to

select and source materials and fasteners, as

well as “Finishes for CNC Projects” on page

210, if you plan to finish your chair.

The Lounge Chair parts are laid onto two 4′×8′

sheets, in order to align grain direction on the

seat and seatback, and to orient the parts so

that the grain wraps around the front, back,

and sides of the chair. This layout leaves ample

surplus space on each sheet to cut test pieces

or the chair’s assembly jig (explained in “Using

the Jig” on page 248).

When you have extra material on a sheet,

sometimes it makes sense to cut parts for a

small project, like the Rotational Stools in

Chapter 7.

DESIGN DECISIONS: 2D AND 3D

MODIFICATIONS

For information on how to customize your

design in CAD, refer to “Design Decisions: 2D

and 3D Modifications” on page 225. As a three-

dimensional, volumetric furniture piece, the

90-Minute Lounge Chair is a complete project

on its own. As with the 5-30 Minute Chair, you

can further tailor the lounge to suit, by either

modifying the flat parts or transforming the 3D

model in the CAD file.

2D MODIFICATIONS

The Lounge Chair seat and seat back offer large

surface areas for cutting, etching, or pocketing

2D embellishments or patterns. Figure 11-1

shows a version of the Lounge Chair, custom-

ized for Makerbot Industries. A pattern of cir-

cles, drawn directly onto the 2D parts in the

CAD file, stretch across the seat and seat back.

Toolpathed and milled as pockets (see “Create

Pocket Toolpaths” on page 242), the circles

received colorful, 3D printed marquetry, made

by Makerbot’s Botfarm.

To make 2D modifications, simply open

AtFAB_LNG.skp and draw directly on the appro-

priate toolpathing layer. Refer to Chapter 3 for

preparing the modified CAD file for toolpathing

in your CAM program. Save the file.

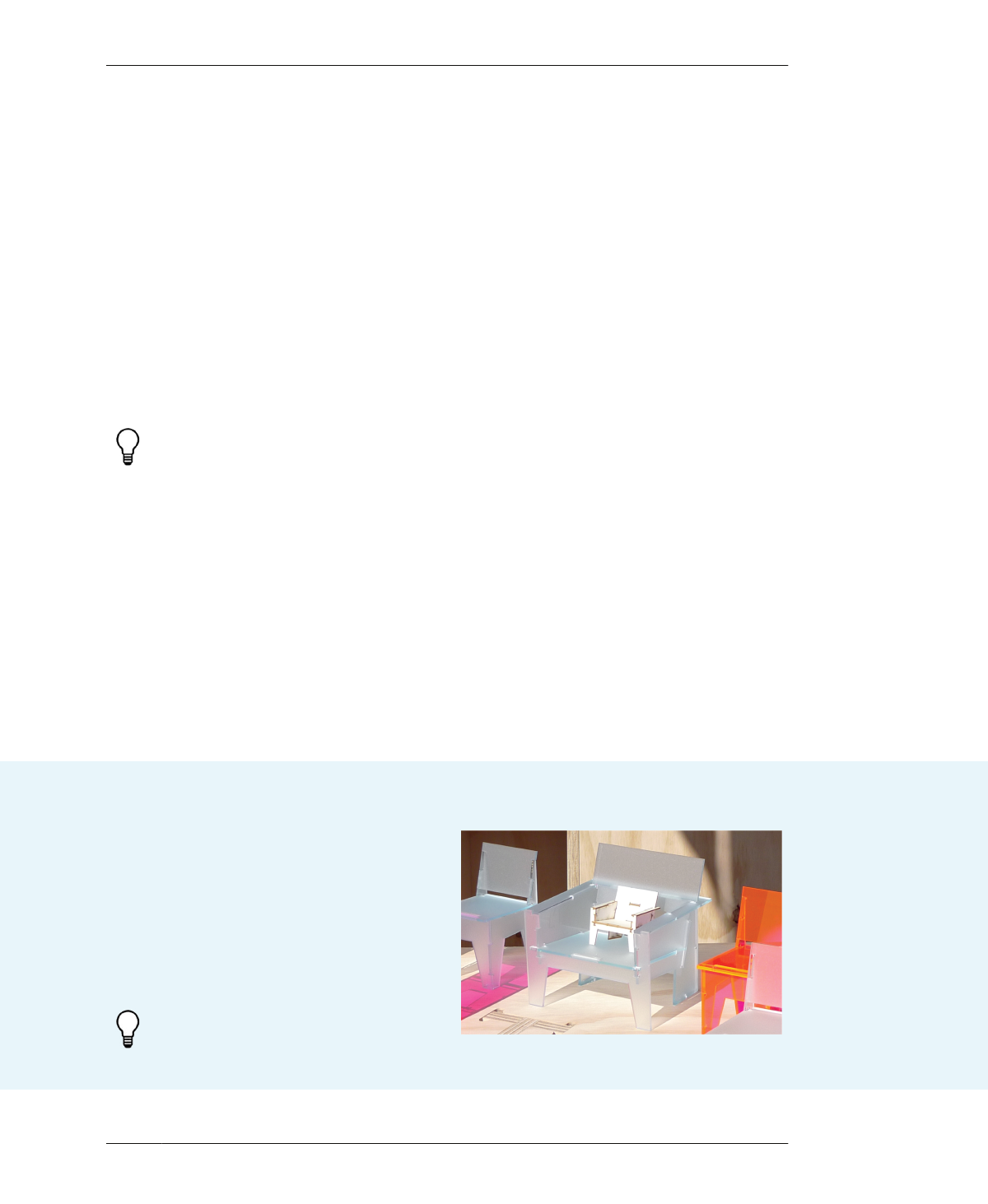

MAKE A SCALE PROTOTYPE

Since the 90-Minute Lounge Chair is three-dimensionally

complex, a prototype helps you see the overall composi-

tion of added patterns and details in ways that you may

have not visualized on the CAD screen. It also gives you a

chance to empirically evaluate the structural integrity of

more substantial modifications, like elongating the seat.

Refer to “Scale Prototypes” on page 137 on preparing

scale prototypes.

Since it’s nearly impossible to laser-cut pock-

ets to a specific depth, skip cutting the keys.

FIGURE 11-2

Laser-cut Lounge pro-

totype

11/90-MINUTE LOUNGE CHAIR

237