ADJUST AND CUT CHAIR

file (e.g., AtFAB_CHR.crv) that yielded the suc-

cessful test piece.

03: Open the test piece VCarve file, delete the

test piece parts, and import the Chair file.

If you’re planning to paint or add a finish to

your chair, finish all the test piece parts to test

the effects of your finish on the fit of the join-

ery.

04: Assign the toolpaths to the appropriate

vectors. Simulate your toolpathing, check the

cutting sequence, and evaluate the resulting

parts.

ADJUST AND CUT CHAIR

After you’ve cut a test piece with a good fit,

you’re ready to proceed with cutting your Chair.

01: Return to SketchUp and either open your

modified file or download and open the 5-30

Minute Chair file (AtFAB_CHR.skp).

05: Export toolpath operations for machining.

Proceed with cutting the chair parts with your

CNC router.

In addition to the outside and holes toolpaths,

you will now apply the inside toolpath to the

slot in the seat. Ensure that the inside tool-

path comes second in the cut sequence.

02: Scale the 2D parts by the exact scaling

adjustments of your successful test piece.

06: Dust the cut parts as they come off the

machine and file or lightly sand the edges as

necessary. Store your parts carefully.

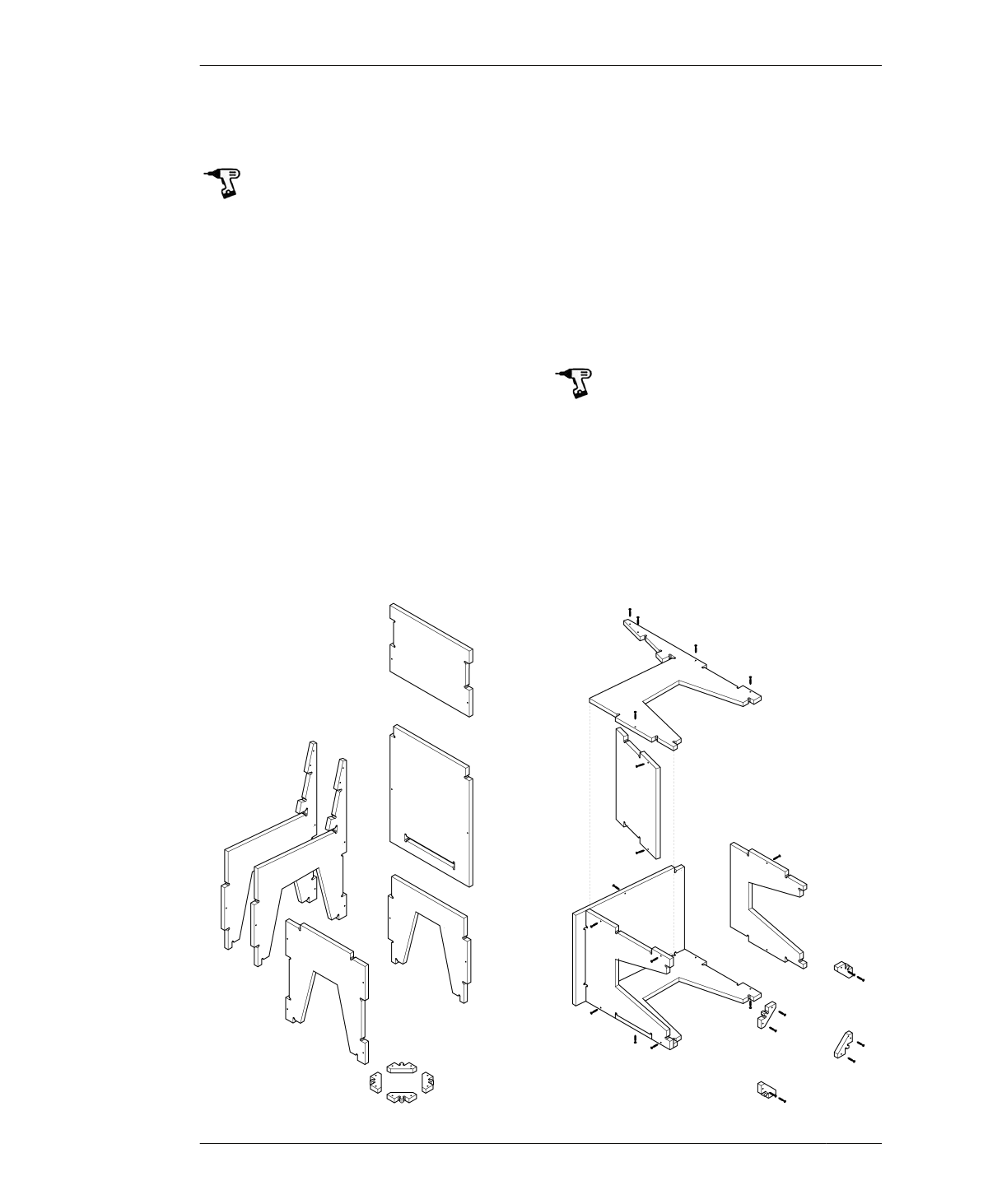

FIGURE 10-10

Assemble the chair on

its side

232

DESIGN FOR CNC