MEASURE AND SCALE

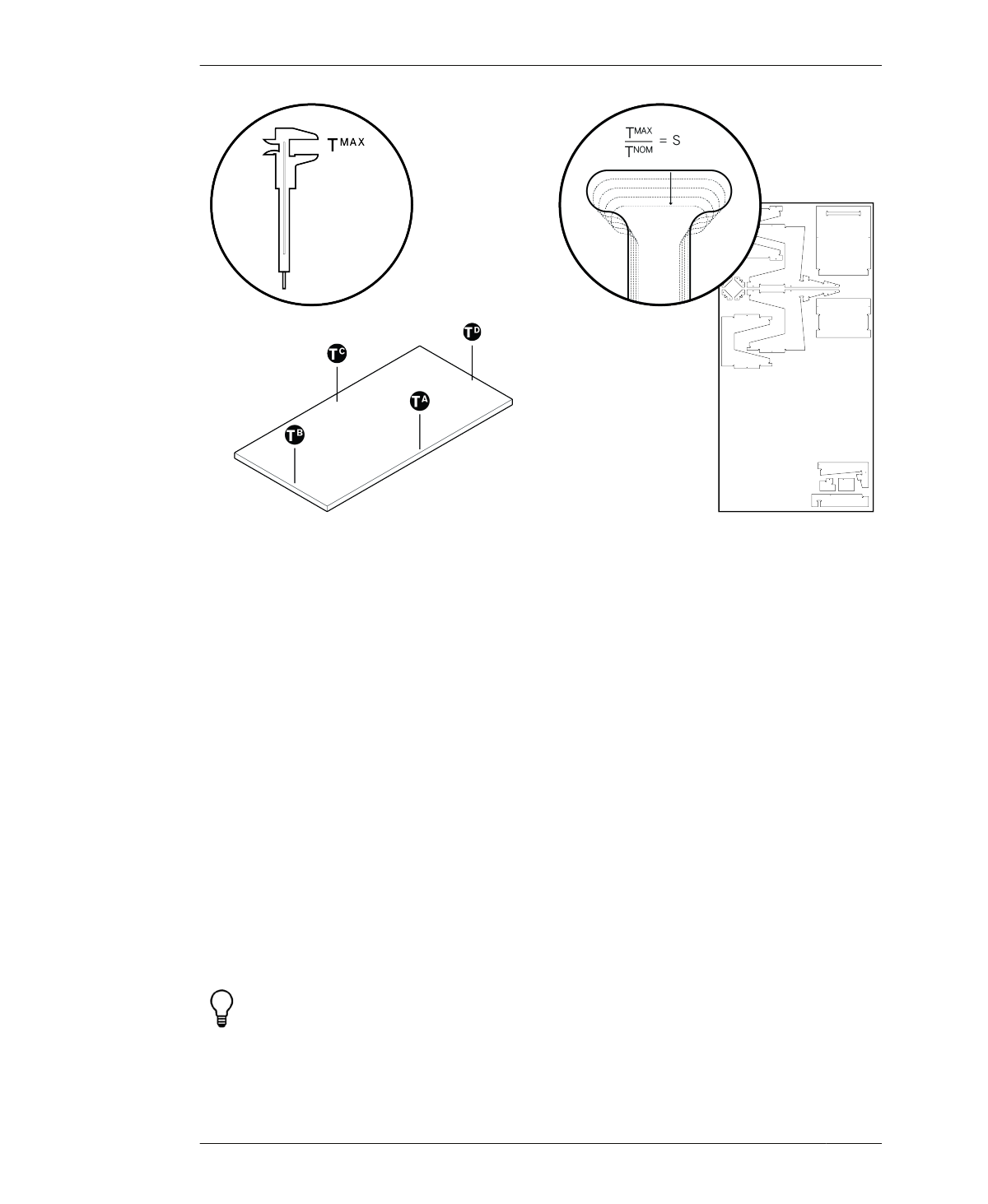

FIGURE 10-7

Measure the material

and the scale file

MEASURE AND SCALE

Once your design modifications are complete

and validated with a scale prototype, or you are

working with the original chair file, you are

ready to prepare for fabrication.

01: Once you’ve procured your sheet material,

review “How to Digitally Dial In Joinery Fit” on

page 131.

02: Thoroughly measure your sheets, recording

TA, TB, TC, TD, as illustrated in Figure 10-7.

In the next steps, you will scale the test piece

CAD file by S, create the toolpaths, cut the files,

and evaluate how well the parts fit together.

CREATE THE PARTIAL

PROTOTPYE

With your material measurments confirmed,

and your scaling percentage calculated, you’re

ready to create a partial prototype (test piece)

to confirm that your full-scale chair will fit

together properly.

03: Calculate TMAX, your actual material thick-

ness.

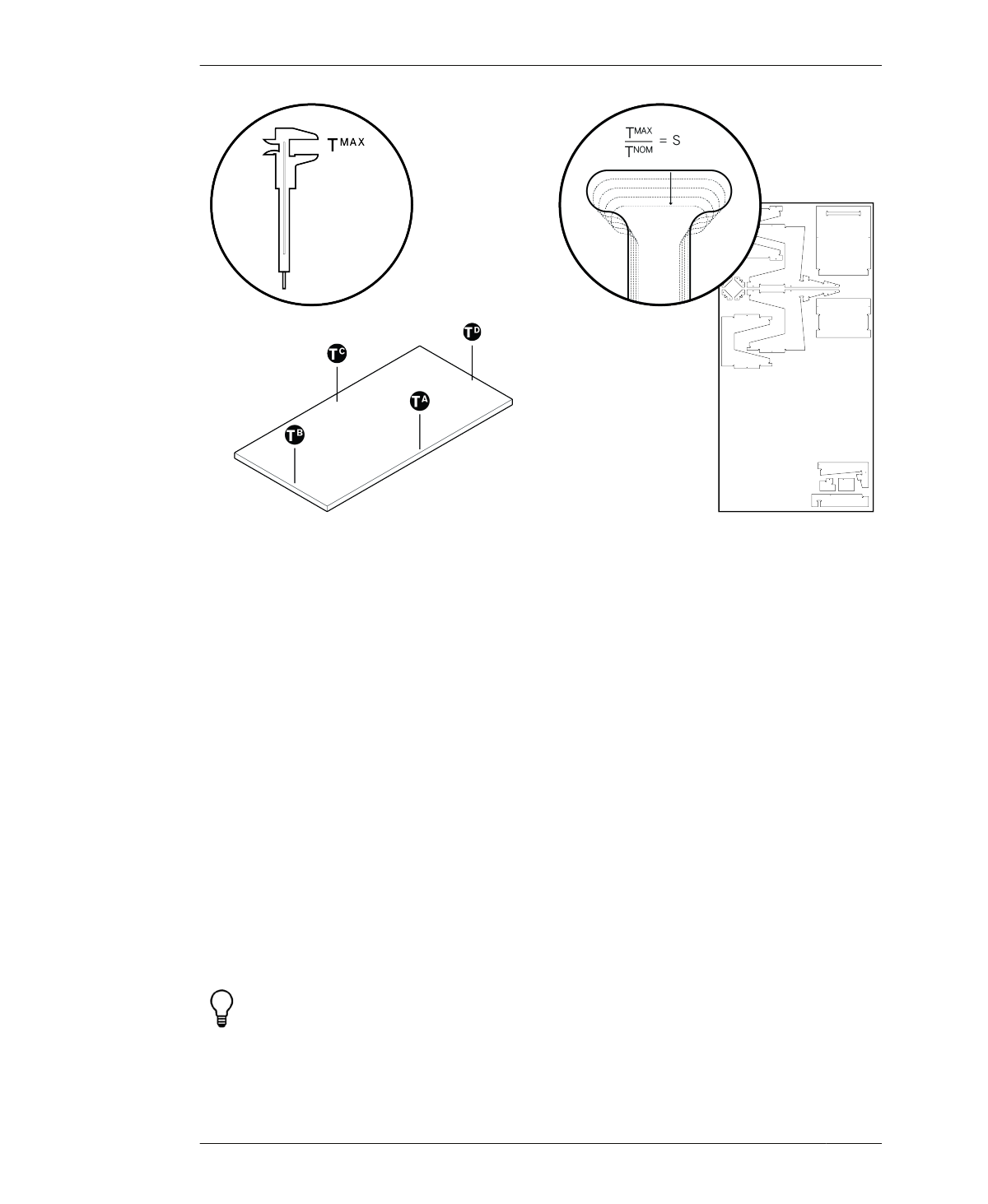

04: Divide TMAX by TNOM to calculate your file

scaling percentage (S).

For detailed information on measuring and

scaling, refer to “Measure Your Materials” on

page 132 and “Scale Your CAD File” on page

133.

01: Visit the book’s website (http://

www.designforcnc.com/) to download the

5-30 Minute Chair test piece

(AtFAB_CHR_TEST.skp).

The chair test piece simulates the connections,

where the front part tabs into the seat, and the

back and seat slot into the side part. Regard-

less of any modifications that you’ve made to

the CAD file, this test piece should still simulate

critical fit conditions. A successful test piece

230

DESIGN FOR CNC