APPLY TEST PIECE SETTINGS TO THE FULL-SCALE FILE

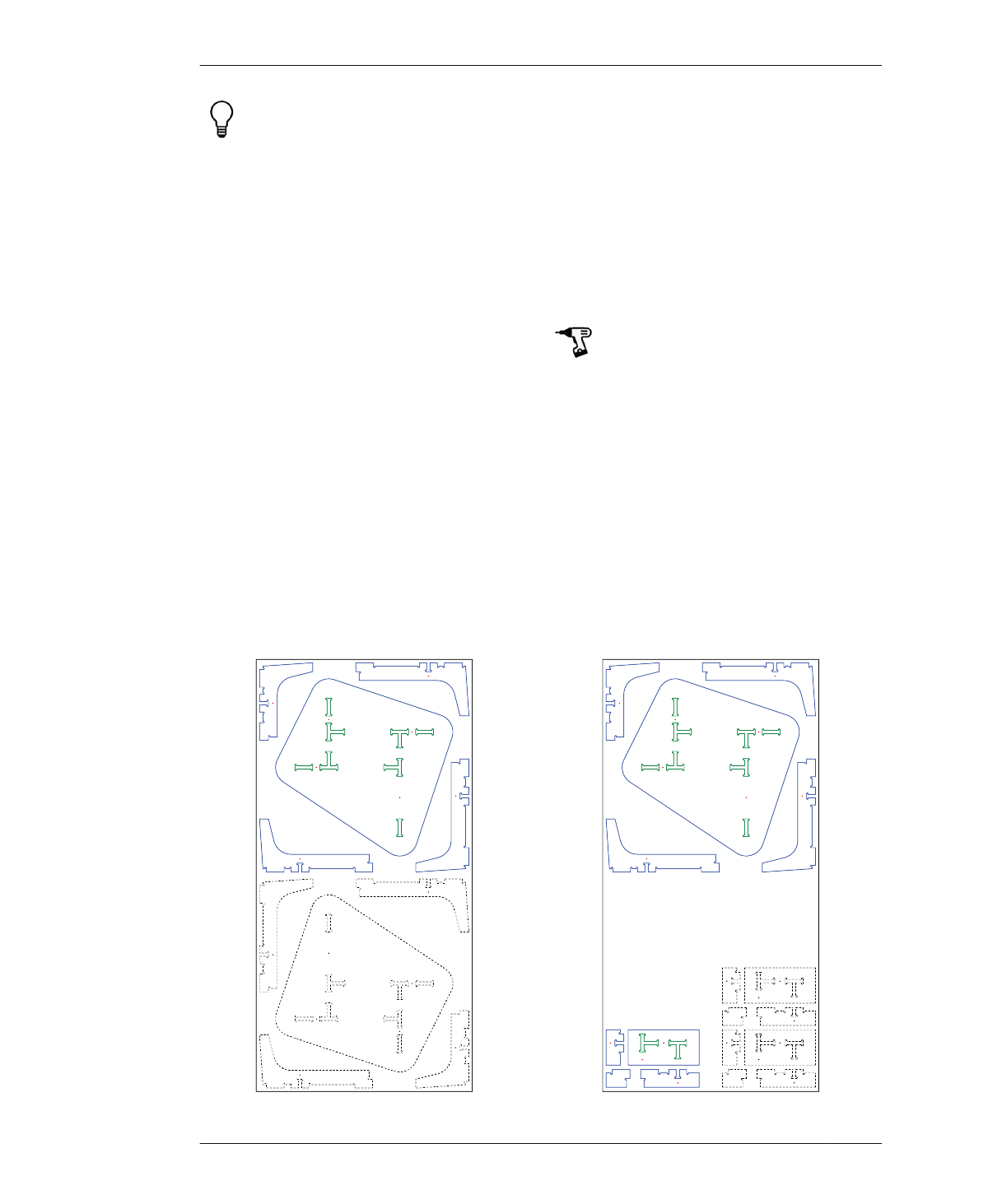

FIGURE 9-6

Placing test piece on

far end leaves clear

area for cutting addi-

tional test pieces and

table parts

If the parts don’t fit, it’s because your finish

adds too much resistance or thickness. To

solve this problem, rethink your finish applica-

tion technique. Or, if you can’t reduce the fin-

ish thickness, you can make CAD and CAM

adjustments to accommodate it.

21: Refer to “Troubleshooting” on page 202 and

make additional test pieces until you finally

achieve an optimal fit with your finished parts.

RECORD SETTINGS AND

ADJUSTMENTS

Once you have a successful test piece, make a

note of all the settings, adjustments, and finish-

ing techniques that combined to produce a per-

fect fit.

22: If you made additional CAD scaling adjust-

ments, calculate the original percentage

adjustment with any additional scaling adjust-

ments.

23: Save only the VCarve file with the toolpath

settings that produced the successful test

piece (e.g., AtFAB_CiBii.CRV).

24: Outline the steps or techniques that yielded

the nicest finish on your test piece parts. With

this information, you’re ready to cut your table

with the confidence that every piece will fit per-

fectly together.

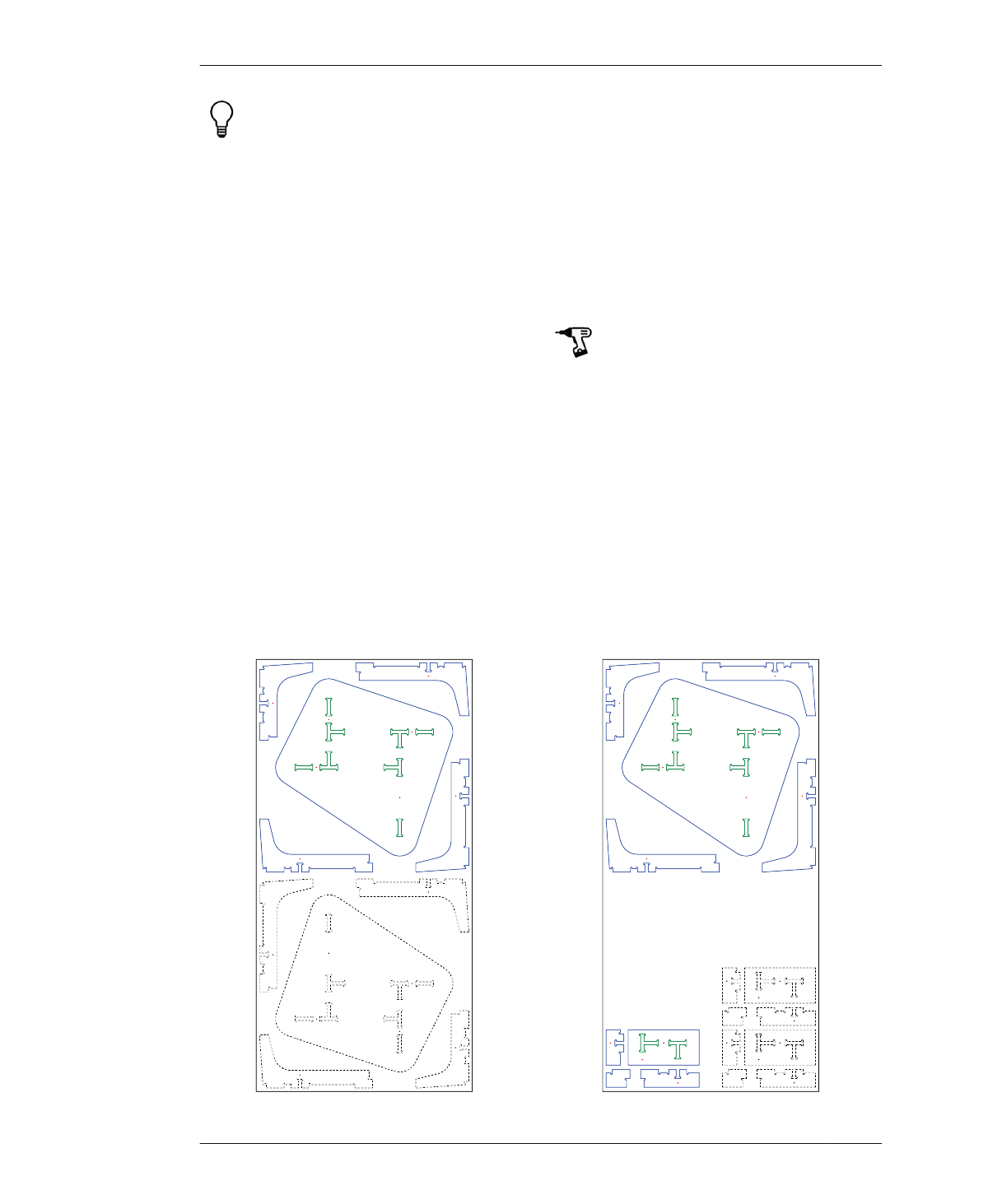

As shown in Figure 9-6 the Cat in Bag ii Table

layout can nest two tables onto a single sheet.

If this is your first time using a test piece, how-

ever, we recommend cutting one table and

using the remaining extra half sheet for cut-

ting multiple test pieces.

APPLY TEST PIECE SETTINGS TO

THE FULL-SCALE FILE

Now that you’ve cut a functional test piece, it’s

time to put those settings to work on the table

files.

216

DESIGN FOR CNC