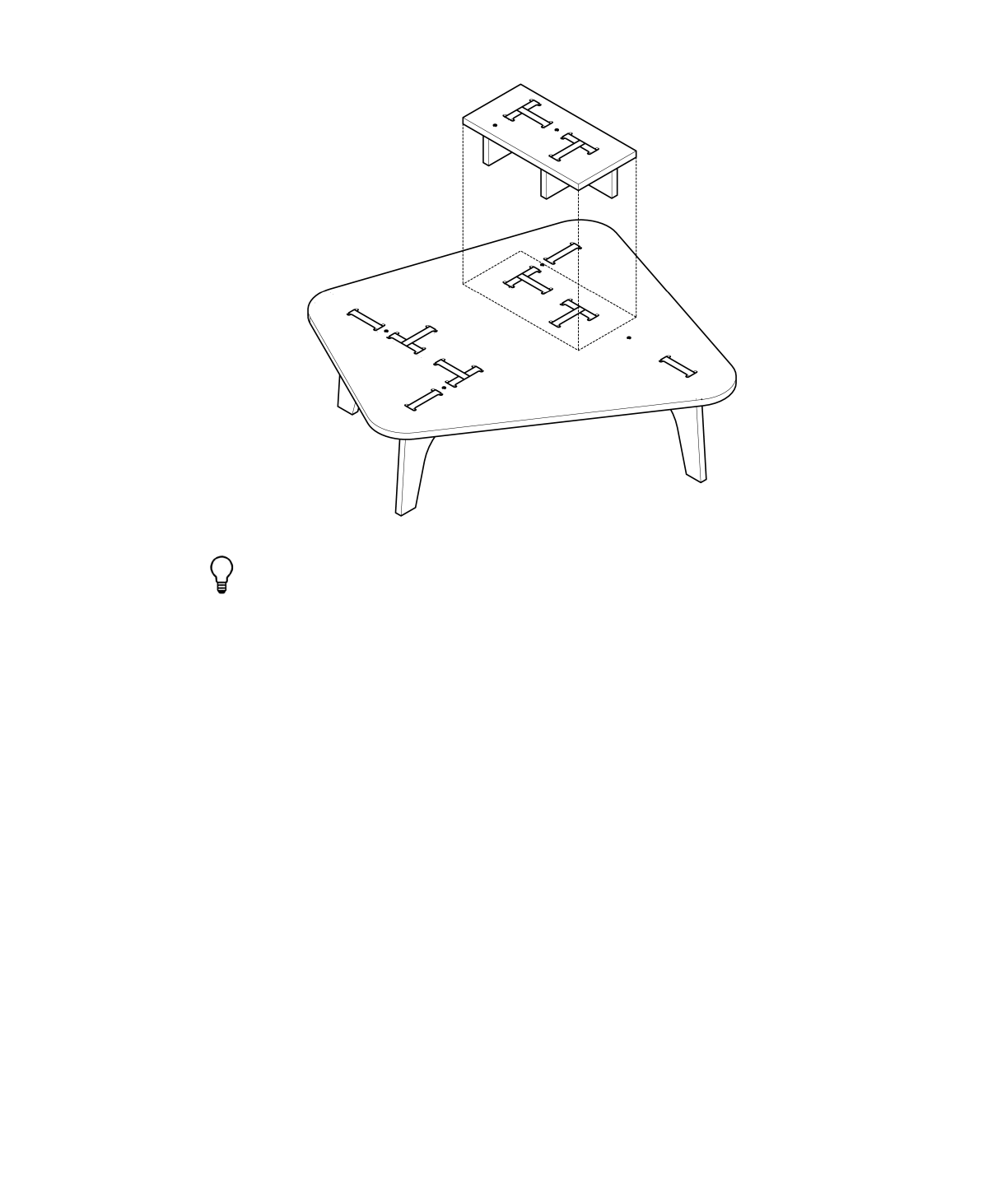

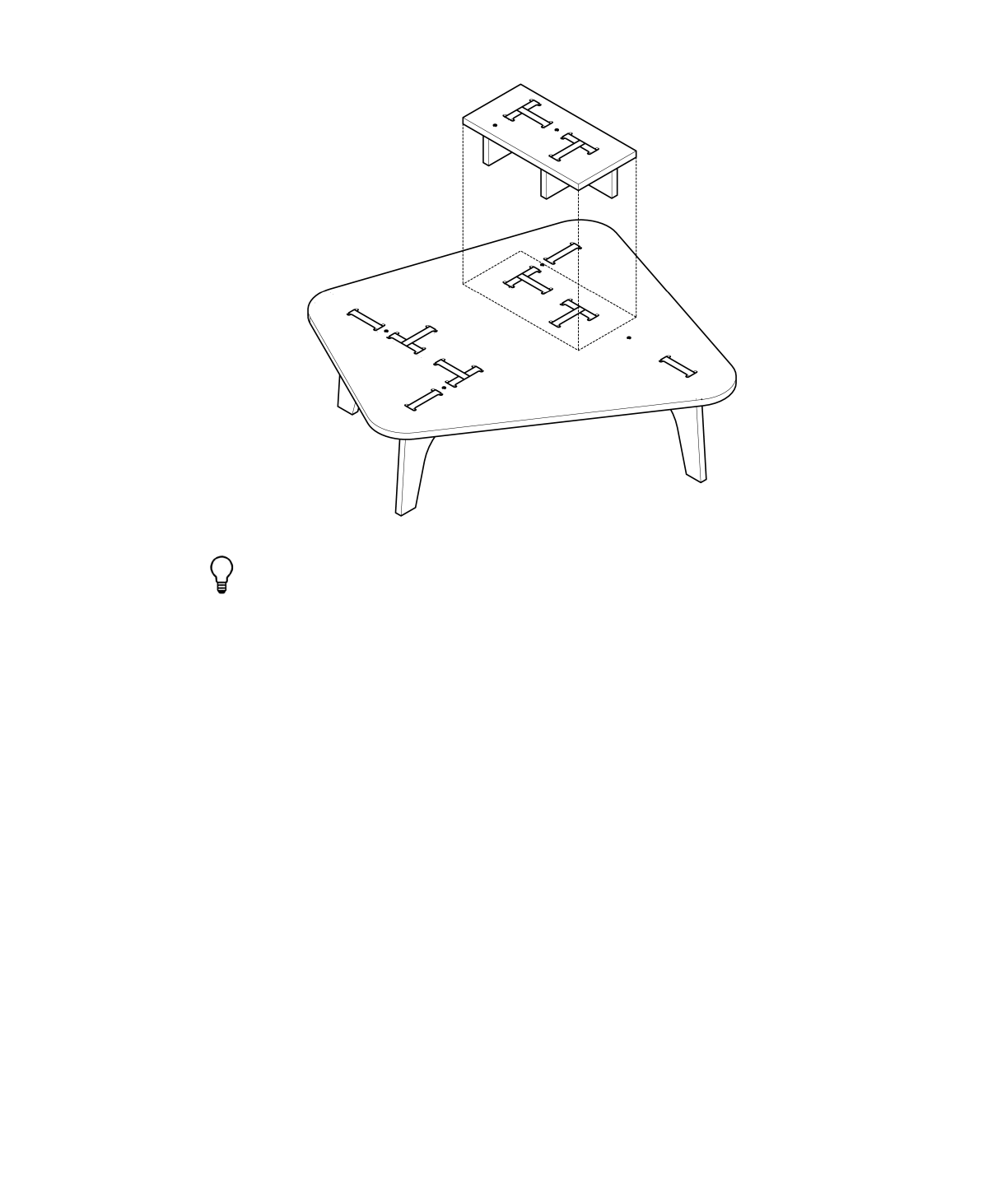

FIGURE 9-2

Test piece for Cat in

Bag ii Table

Most products indicate the amount of surface

coverage right on a package, making it easy to

figure out how much finish you need when

working with flat parts. Simply calculate the

surface area of both sides of all 2D parts and

select the correct amount of product.

PARTIAL PROTOTYPING: USING A

TEST PIECE

The Cat in Bag ii Table (and the projects we’ll

work on after it) involves much more material

and cut time than the Rotional Stools. Although

the measuring and scaling process is intended

to produce flush-fitting joinery, what happens if

you’ve incorrectly recorded material thickness

or accidentally scaled by the wrong factor?

Testing the joinery fit with a small, partial proto-

type, or test piece (introduced in “Test Pieces”

on page 136), is an important step that will help

prevent cutting an entire table with incorrect

settings—avoiding frustration and material

waste.

The Cat in Bag ii test piece, shown in

Figure 9-2, simulates the critical joints where

the tabletop and interlocking legs intersect.

Since the test piece is much smaller in size

than the table, you can easily cut several ver-

sions of them (if necessary), in order to estab-

lish the settings for a perfect fit.

Next, you’ll walk you through the process of

using a test piece. You’ll scale the test piece

CAD file (AtFAB_CiBii_TEST.skp), define CAM

settings, cut the test piece from your material

stock, and evaluate the parts for a proper fit.

After you have a test piece with joinery that fits

perfectly, you’ll apply those exact CAD scaling

and CAM settings to the table file

(AtFAB_CiBii.skp) and confidently proceed with

cutting the table from your material.

212