FINISHES FOR CNC PROJECTS

Translucent and Clear Coatings

Permanent clear finishes will protect parts from

dust and scratches, and sometimes even mois-

ture or sun exposure. Wipe-on acrylic and poly-

urethanes require multiple coats, but they soak

in and add a minimal thickness to cut parts.

When applied sparingly in advance of a clear

coat, stains, analine dye, and milk paint provide

a rich, translucent color that allows the grain to

come through.

Painting

Applying latex or oil paints is another option.

Spraying is much less labor-intensive than

working with a paintbrush, and allows you to

build up a painted coating, while controlling the

thickness. With a paint booth and some prac-

tice, it’s even possible to achieve a shiny, lac-

quered coat of hard-wearing enamel. Since

paint thickness affects the fit of joints, it’s

especially critical to paint test pieces and cali-

brate joints before cutting a final furniture

piece.

Color, Then Cut

Another way to introduce color into a project is

to prepaint the plywood sheets prior to cutting

parts on the CNC router. Allow the paint to

thoroughly dry or cure overnight, and the CNC

end mill leaves a very clean, crisp raw edge that

contrasts with the painted face.

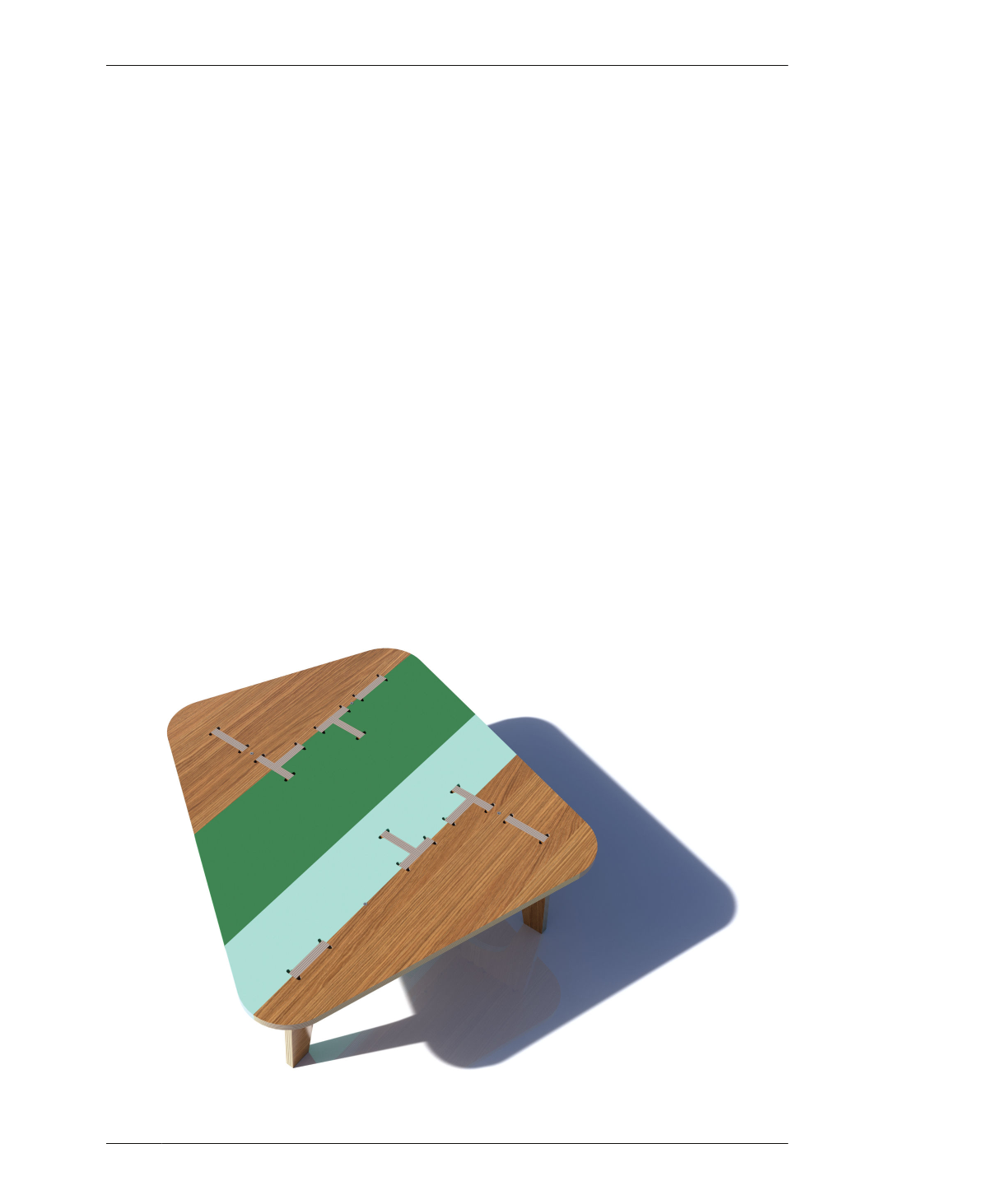

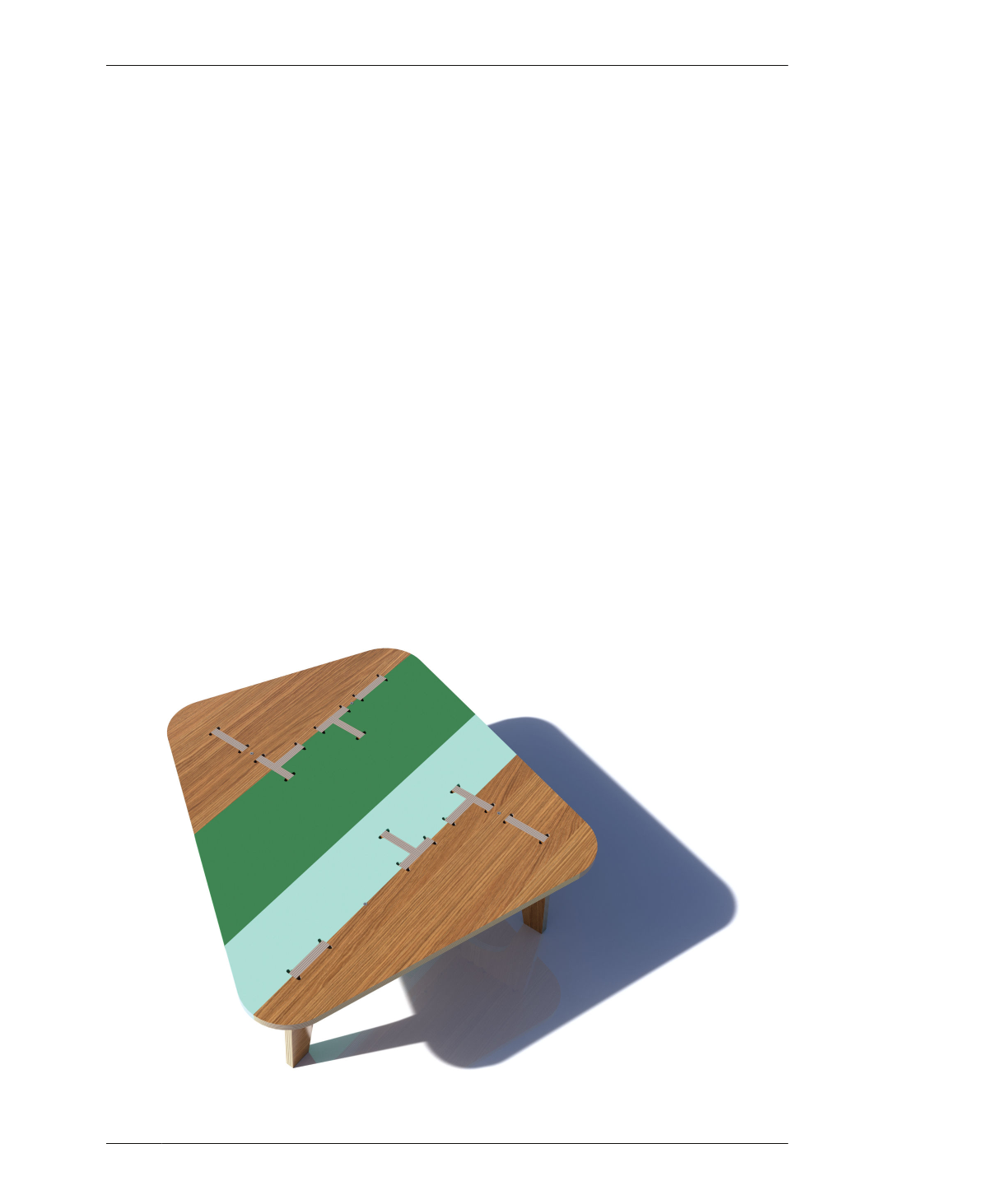

Color Blocking

Color and finish also don’t necessarily need to

be applied to an entire piece of furniture. With

the help of masking or stencils, you can apply

color blocking, stripes, or patterns onto a furni-

ture piece after fabrication and assembly, as

shown in Figure 9-1.

FIGURE 9-1

Color-blocked table

09/CAT IN BAG II TABLE

211