FASTENERS

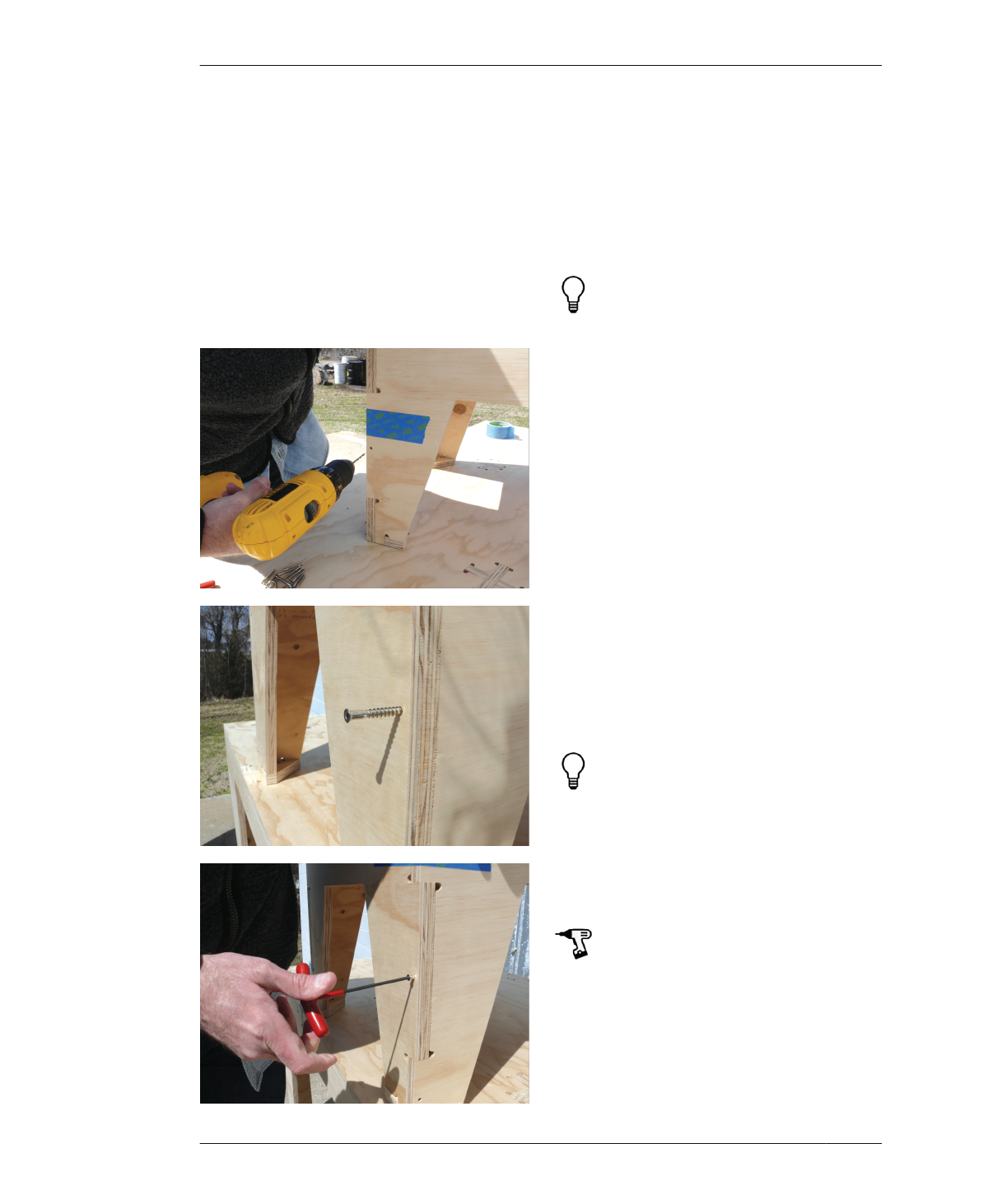

FIGURE 8-6

Drill through pilot hole

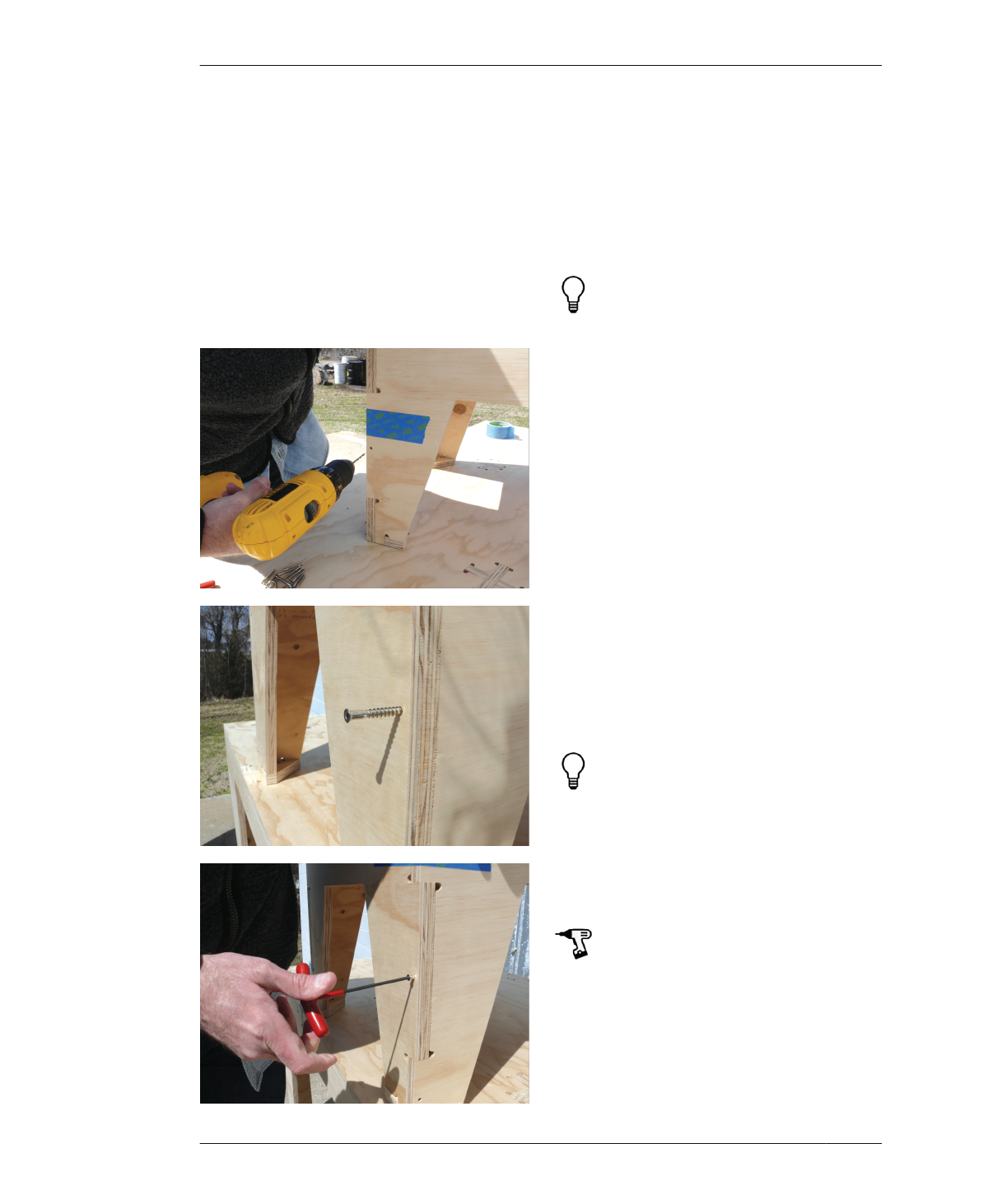

FIGURE 8-7

Insert fastener

1 ½″ and shank diameter that fits within the 1⁄8″

fastener hole, the screw is perfectly sized for

¾″ plywood parts.

HOW TO DRILL

While the CNC router predrills holes into the

face material, you’ll still need to manually drill

holes into the edge of the opposing part for

pegs and hardware. Predrilling holes for pegs is

a necessity. Though predrilling prior to

screwing in fasteners may seem optional, it’s

actually a good practice for many reasons. It

prevents splitting of the plywood plies, and also

allows a clean contact between the fastener

threads and the hole. Also, you’ll have a greater

choice of fasteners, if you’re not relying on self-

tapping screws.

Use the hole cut by the CNC as a pilot hole,

helping you perfectly locate the fastener and

align your drill.

01: Piece furniture parts together and secure

with blue painter’s tape (Figure 8-6).

02: Predrill all holes for fasteners (Figure 8-7).

Start by working around the sides, before drill-

ing seats and tops. For furniture pieces with

feet, save the feet for last. Drill directly through

the pilot hole cut by the CNC machine, keeping

your bit perpendicular to the face. Drill into the

edge of the opposing part, matching the drill-

ing depth to the length of your fastener.

03: Screw in fasteners, matching the drilling

sequence. Start by securing the sides to each

other first, then attach seats (or tops), and

then feet (Figure 8-8).

FIGURE 8-8

Tighten fastener by

hand

Consider the starting point and sequence of

drilling and fastening. It helps keep joinery

aligned when you drill and fasten from the

center of the furniture and work outward to

the edges, corners, and feet. Working

methodically will also help prevent missing a

hole!

Be careful not to over-rotate when screwing

fasteners into the material. Heads should be

flush, and not pressed into the face veneer.

206

DESIGN FOR CNC