CUT AND EVALUATE FIT

actual thickness, TMAX. Divide TMAX by TNOM

to find your scaling percentage (S).

Download and open ATFAB_STL.skp. Refer to

“Scale Your CAD File” on page 133 and scale all

Rotational Stool part toolpaths by S so that

they match TMAX. Import this scaled CAD file

into VCarve and follow “Job Setup” on page 170

to define toolpaths for your scaled file. Once

you have saved your scaled toolpath operations

for output, you are ready to fabricate.

CUT AND EVALUATE FIT

Proceed with cutting your first set of parts on

the CNC. After cutting is complete, gather all

cut parts from the sheet, dust each part off,

and stack similar parts together on a work sur-

face.

EVALUATE THE LAZY STOOL

Piece together several parts of the Lazy Stool,

handling each part carefully. Hold parts so that

they are squarely aligned and feel the face of a

tab relative to the face of the adjacent part. Is

the tab flushly aligned with the face? Or does

the tab extend beyond the face (or vice versa)?

While perfect flushness between these two sur-

faces is your objective, the Lazy Stool will still

be functional even with parts that are less than

flush. The Lazy Stool has edge-to-edge and

edge-to-edge-to-edge joints, which are more

forgiving than the interlocking through and end-

to-face connections of the Lively Stool. You

won’t really know how well your parts fit until

you test complex, multi-sided joinery, like the

connections found in the Lively Stool.

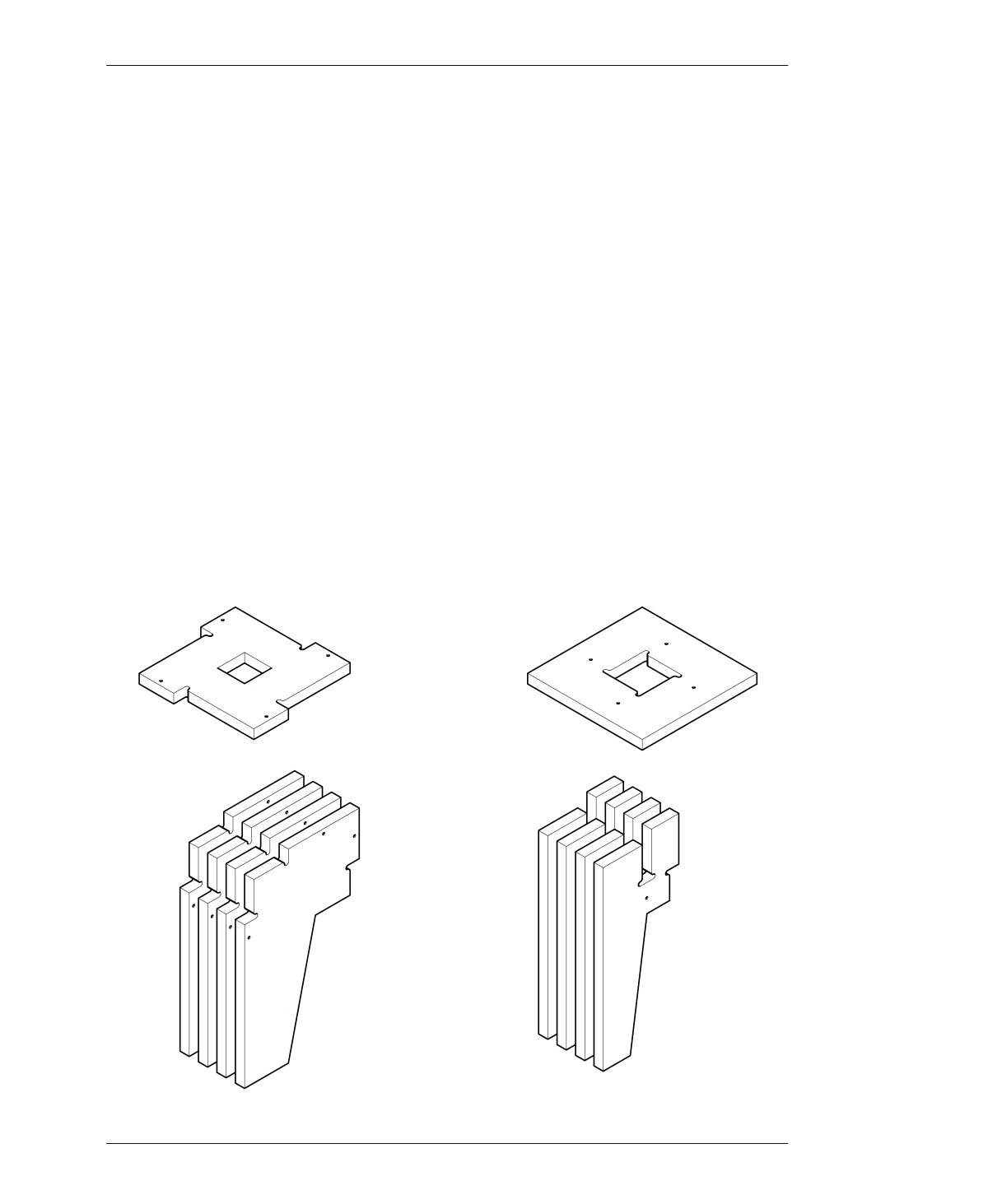

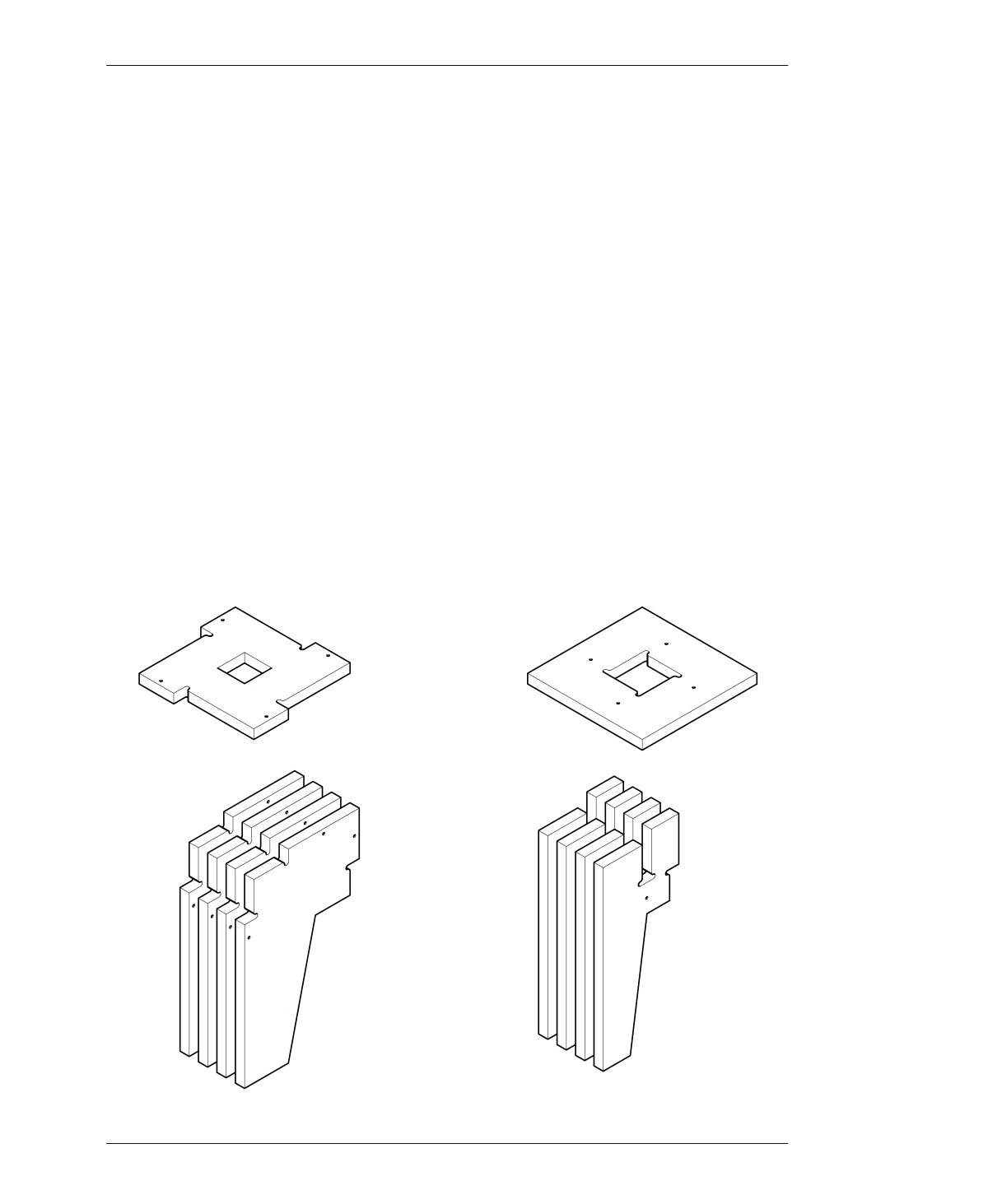

FIGURE 8-2

Cut parts for the Lazy

(left) and Lively (right)

Rotational Stools

08/ROTATIONAL STOOLS

201