ABOUT THE DESIGN

ABOUT THE DESIGN

With a substantial amount of joinery packed

into a few small, simple parts, the Rotational

Stools are an ideal first project. Both stools

share the same overall outer dimensions, and

both are comprised of five pieces, with two part

types. Each stool has four identical leg parts,

which are organized into a rotational structure

that interlocks into the seat (see “Structures”

on page 56). What differentiates the stools is

how each utilizes different types of joinery.

Lazy fingers are used to join the “Lazy” stool

(left), while the “Lively” (right) has tight,

through connections. While originally designed

as small stools, many find that the pair work

equally well as mini side tables.

BEFORE YOU BEGIN

To cut a pair of Rotational Stools, you only need

a partial sheet of 4’ × 8’ × ¾″ material. How-

ever, you may prefer to purchase an entire

sheet, so you can use the surplus to prototype,

troubleshoot, or experiment by cutting the

project several times.

Since they are already quite small, the Rota-

tional Stool file isn’t accompanied by a test

piece (explained in “Test Pieces” on page 136),

but we will employ that technique in other

projects in this book. For this project, it’s possi-

ble to cut several versions from a single sheet

of plywood, so you can test various CAD scaling

and CAM setting combinations, and learn the

variables that factor into achieving a perfect

joinery fit.

MEASURE AND SCALE

If you went through “Job Setup” on page 170

without measuring your material and scaling

your cut file, proceed with these steps to pre-

pare a CAD file and CAM settings.

Refer to “Selecting Materials” on page 128 for

guidelines on plywoods and follow the instruc-

tions in “Measure Your Materials” on page 132

to measure your sheet material and identify its

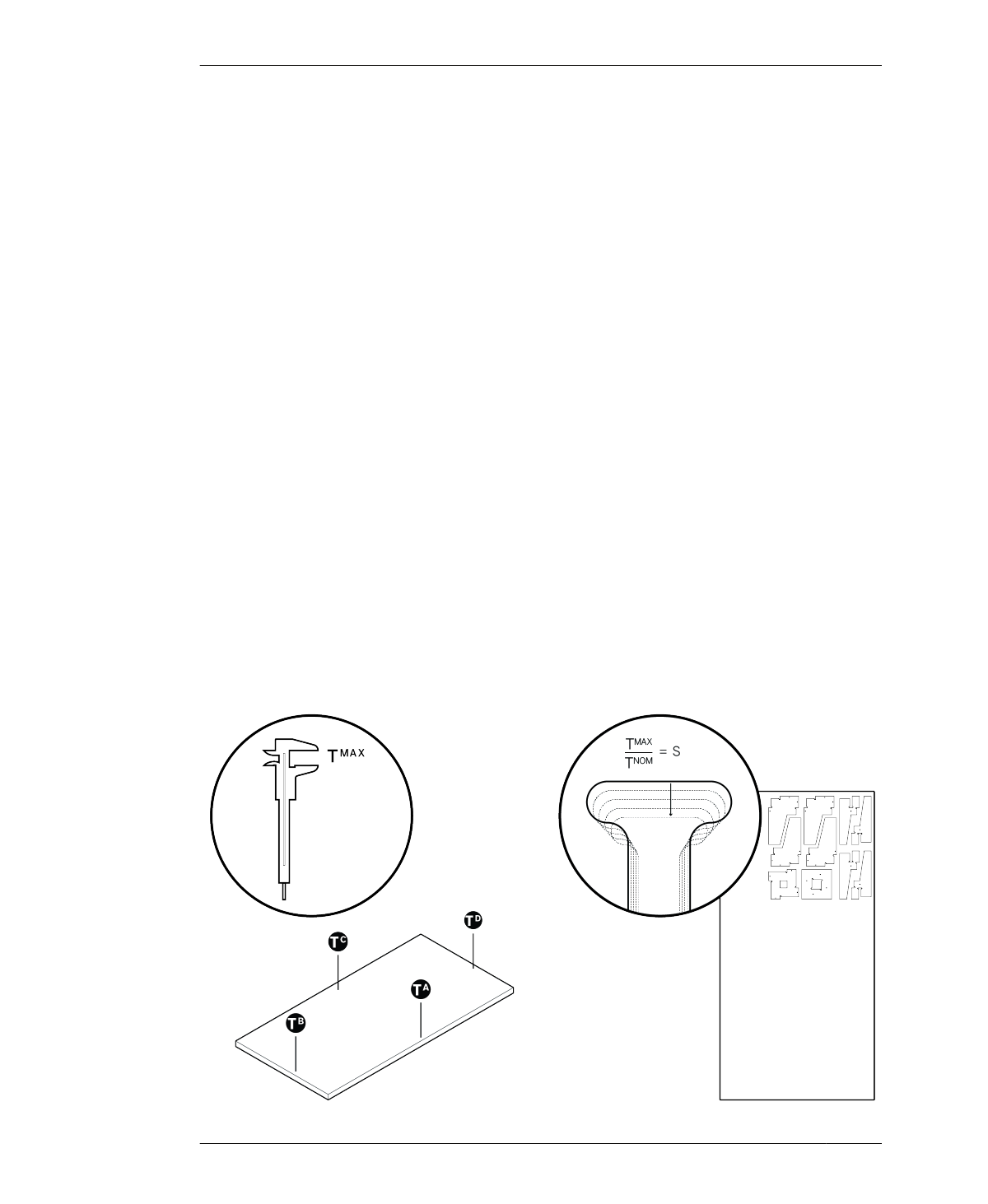

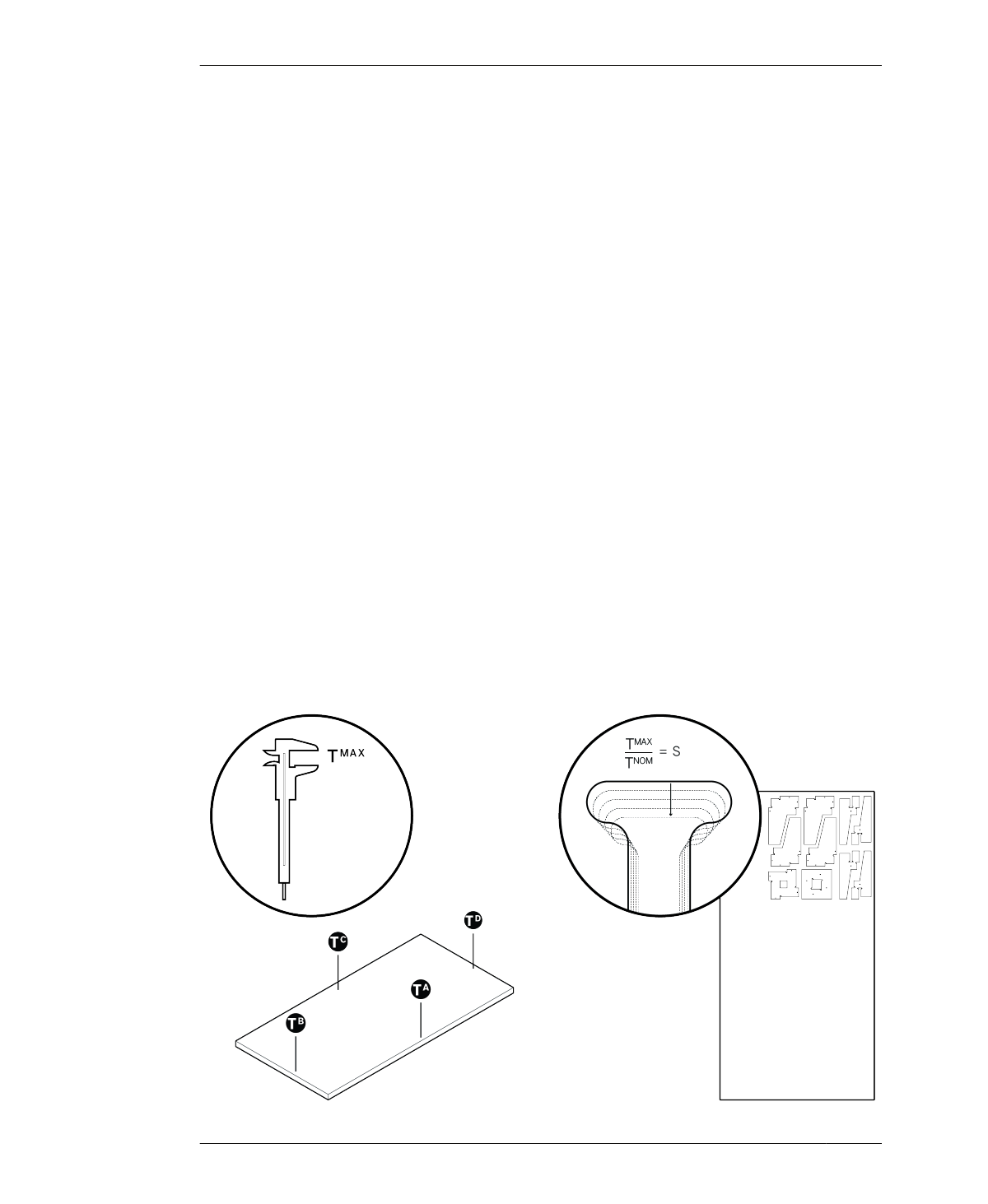

FIGURE 8-1

How to measure and

scale the Rotational

Stools

200

DESIGN FOR CNC