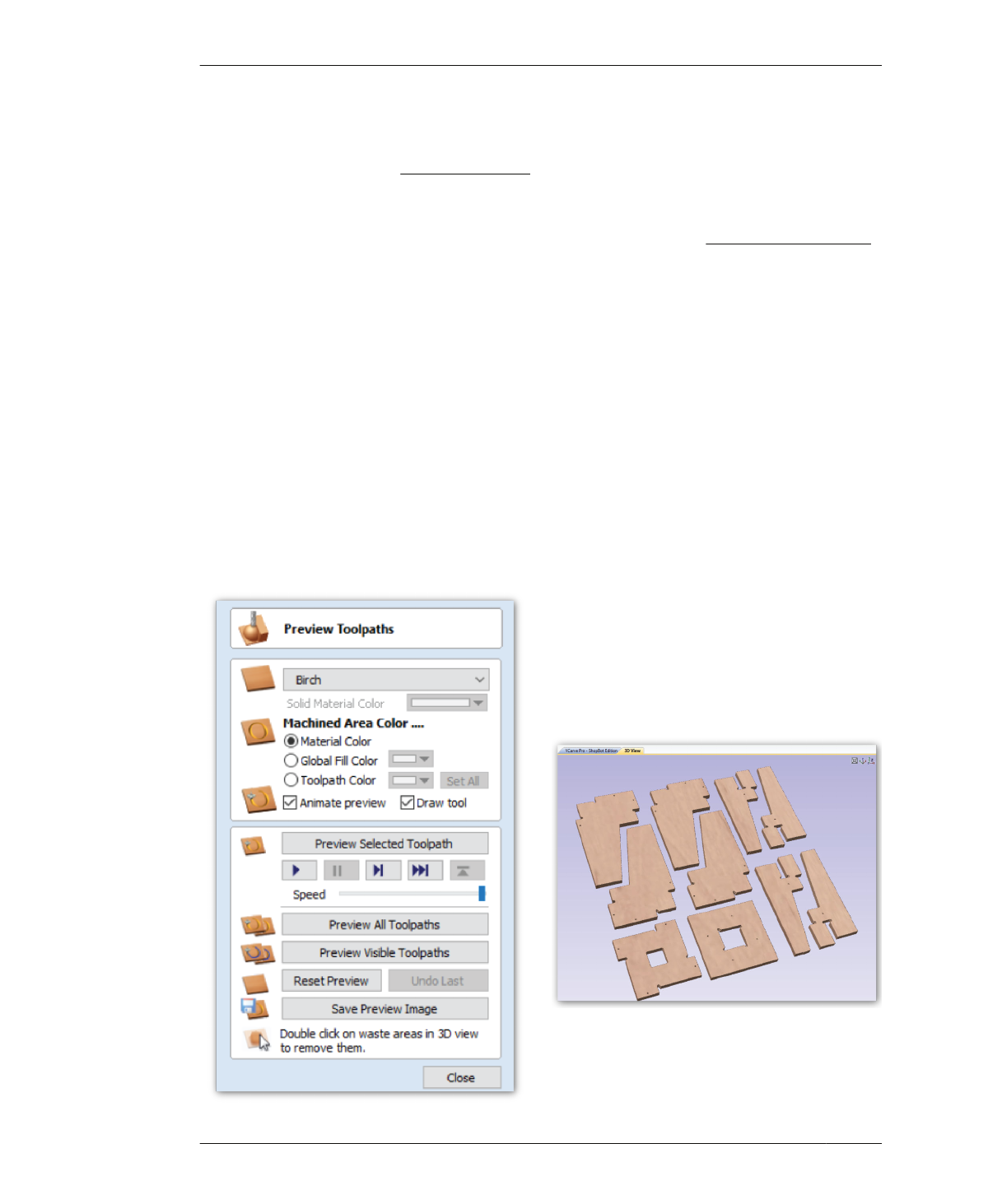

FIGURE 7-46

Visualization Menu

SIMULATION AND ANALYSIS

time-consuming, irreversible, costly mistake—

compared to a misspelling on the page.

VISUALIZE AND ANALYZE

Using multiple kinds of visualization will help

you catch errors made earlier in the workflow

or design process, before you fabricate them.

Experiment with VCarve’s various simulation

and visualization features in the 3D view.

Animated Simulation

35A: Run the animated preview again, but

now with all three toolpaths in the correct

order.

35B: Speed up or slow down the animation so

that you can follow the cutting process.

3D Views

35C: Zoom, pan, and rotate the view to see all

parts.

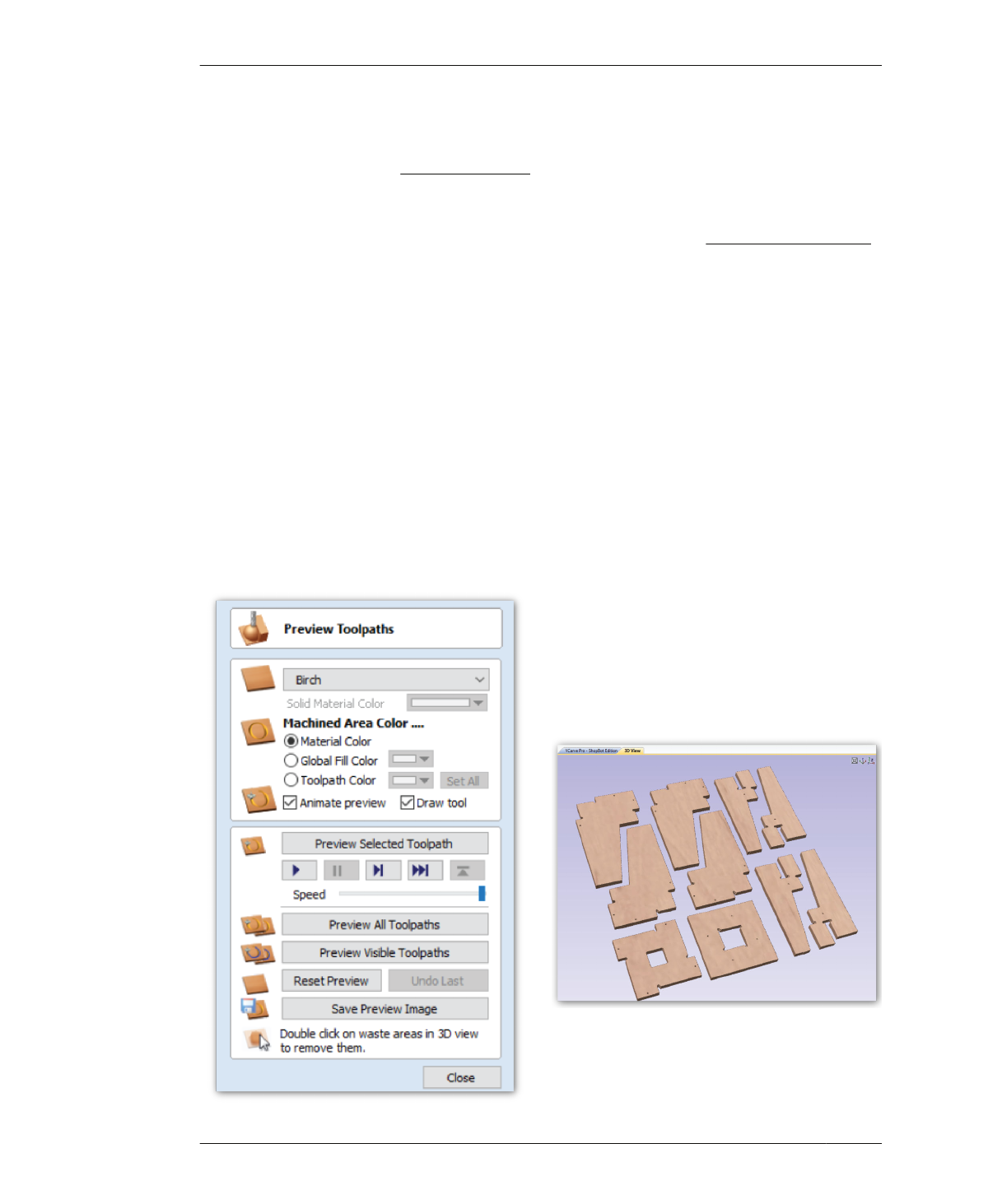

35D: Use Remove Waste Material to examine

the cut parts on their own.

35E: Turn on 2D Profiles to study cut parts rel-

ative to the original vectors.

QUALITY CONTROL

VCarve’s simulation features help you antici-

pate and plan for critical moments in the fabri-

cation process, such as the time it takes each

pass to complete, when the machine stops for

manual end-mill changes, and the order of

parts completion.

36A: Use the simulations to check that all

parts, including sniglets, are shaped properly,

and that the tool cuts every part out in its

entirety.

36B: Is your end-mill diameter too big? Will it

obliterate small details?

36C: Determine whether the tool is cutting

through the material and that all parts are

included in the cut sequence. If you find errors,

you can either adjust your design or increase

your tool size and re-simulate before actually

cutting.

196

DESIGN FOR CNC

FIGURE 7-47 Visualization of cut parts on their own