FASTENER HOLE TOOLPATHS

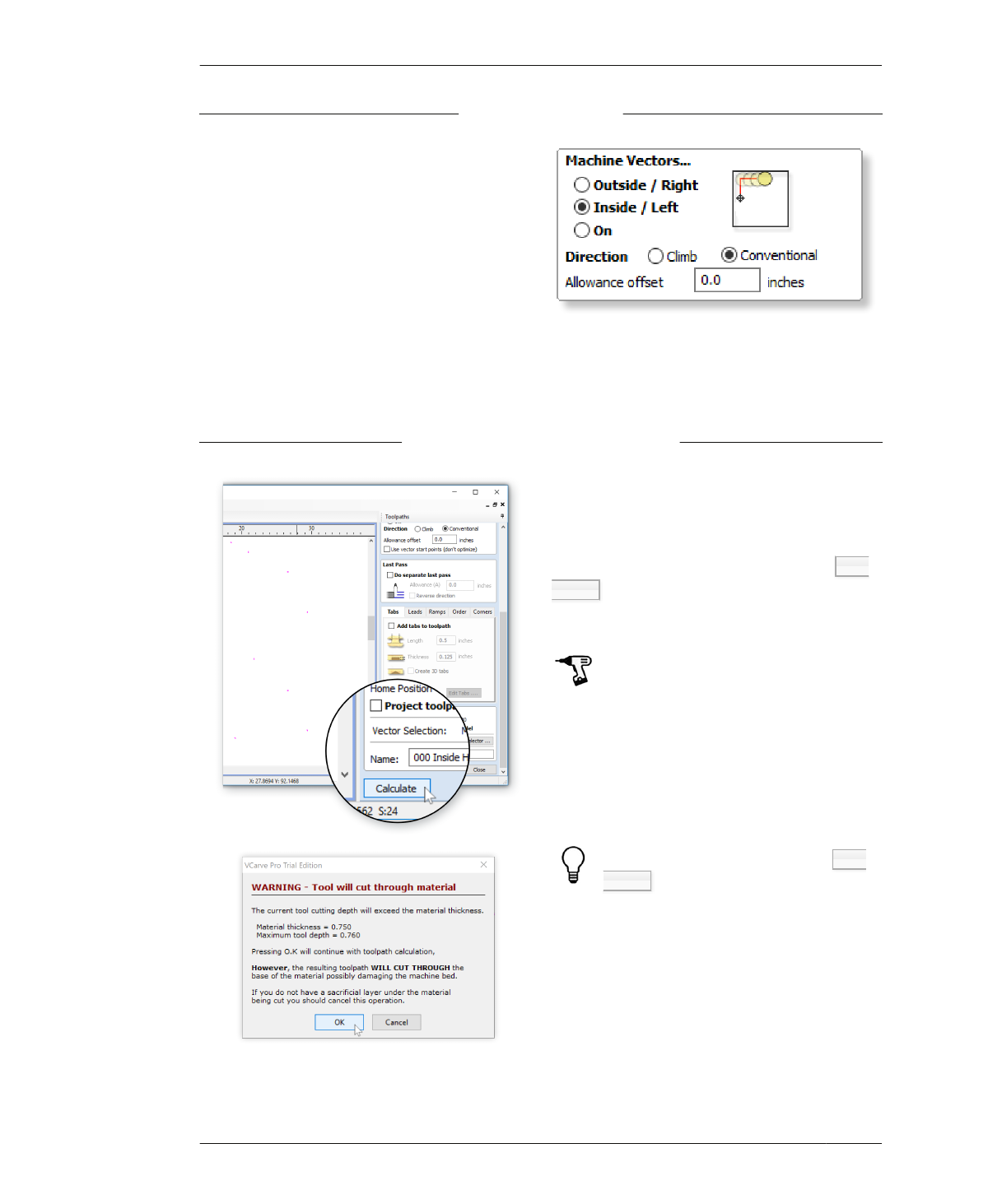

MACHINE VECTORS

To cut accurately sized holes, you’ll need to cre-

ate an inside toolpath that cuts on the inside of

the vectors.

23A: Select Inside/Left and Conventional.

23B: Use the defaults for the rest of the

Machine Vectors options. Keep the “Allowance

offset” at 0.0 inches and keep “Use vector start

points (don’t optimize)” unchecked.

23C: Ignore the Tabs section below Machine

Vectors. Leave the box unchecked.

FIGURE 7-31 Machine Vectors menu

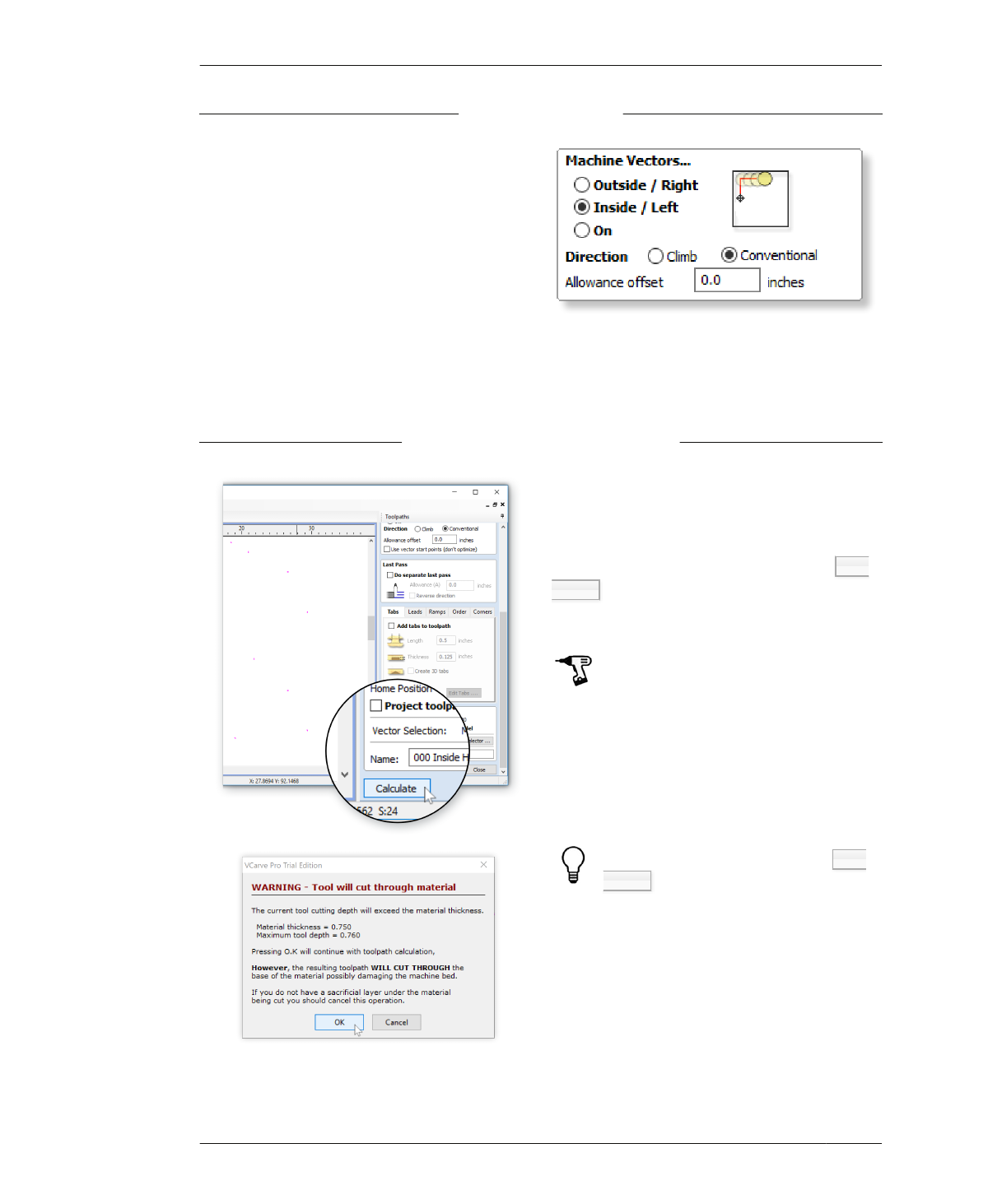

NAME AND CALCULATE TOOLPATH

FIGURE 7-32

Click the Calculate but-

ton to create the tool-

path

24A: Change the toolpath name from “Tool-

path 1” to “000 Inside Holes,” a name that

describes attributes of the toolpath.

24B: Recheck all settings then click the Cal-

culate button at the very bottom of the Tool-

paths menu.

FIGURE 7-33

It’s OK to ignore the

profile toolpath warn-

ing message, because it

pops up every time—

but always double-

check the cut depth

info

By default, a pop-up warning alerts you that

cut depth is deeper than material thickness.

Every time you create a toolpath that cuts all

the way through the material, VCarve will

warn you. It’s OK to ignore the profile toolpath

warning message, because it pops up every

time—but always double-check the cut depth

info!

You may need to scroll down to see the Cal-

culate button (see Figure 7-32).

186

DESIGN FOR CNC