FASTENER HOLE TOOLPATHS

CUTTING DEPTHS

Start Depth (D)

Cutting usually begins on the material’s sur-

face, but if your material isn’t flat, is dirty, or

you simply want to machine away the top layer

for some reason, then you add a start depth to

tell the machine how much material to remove

before it begins cutting the toolpath.

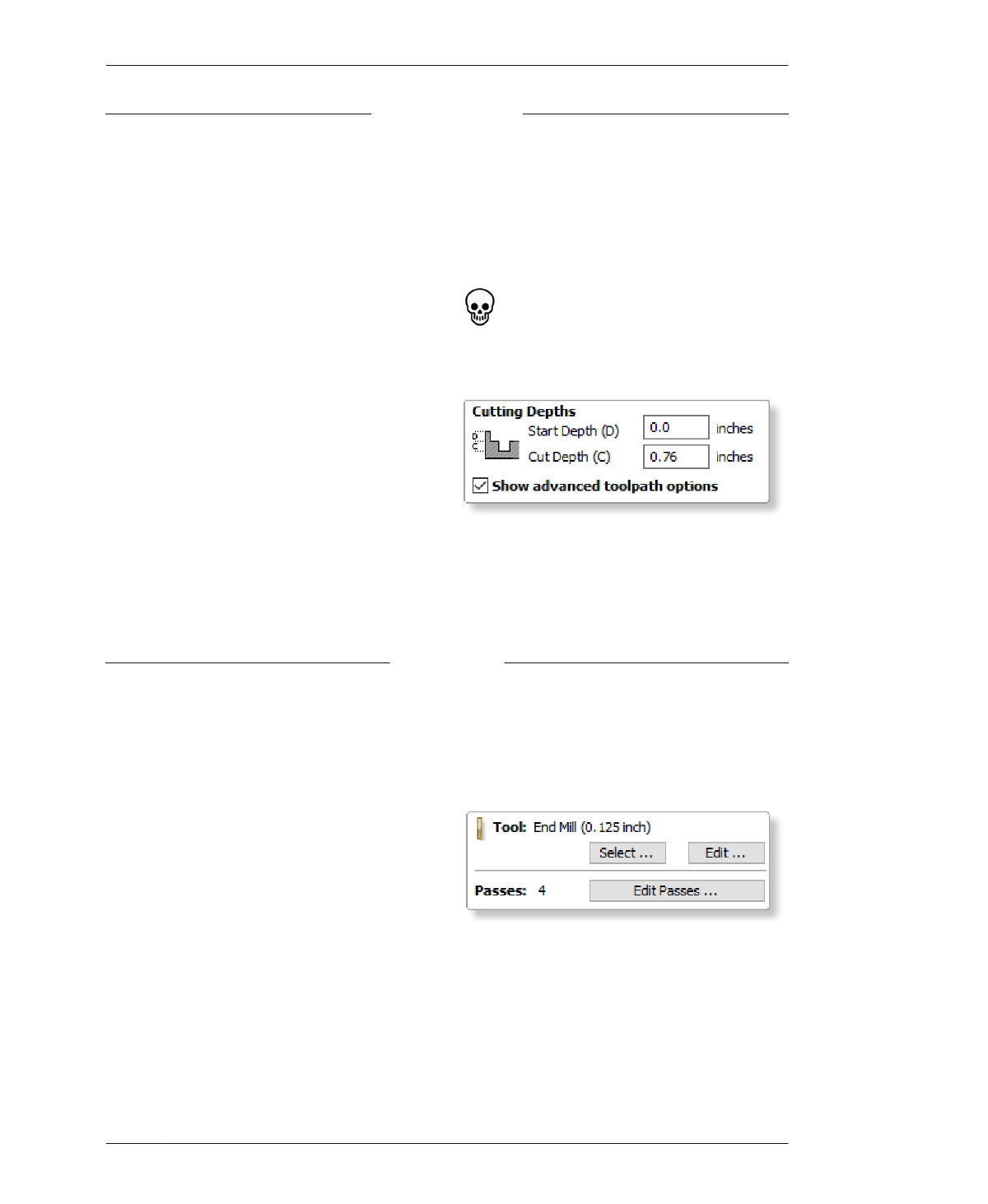

21A: Keep the default Start Depth of 0.0

inches. Plywood has a thin veneer that you

don’t want to remove. The Cutting Depths

options are located at the very top of the 2D

Profile Toolpath menu, Toolpaths→2D Profile

Toolpath→Cutting Depths, as shown in

Figure 7-29.

21B: Set the Cut Depth to 0.76 inches, or

1/100” past the measured thickness. “Show

advanced toolpath options” should be checked.

Because you’re just walking through the exer-

cise, you’re using a nominal thickness (TNOM).

If you’re actually machining, remember to

carefully measure the actual material thick-

ness to calculate TMAX, as explained in

“Nominal Thickness” on page 129.

Cut Depth (C)

Setting cut depth to a small increment past

your material thickness will ensure that the end

mill cuts a profile all the way through. Set depth

to .76” or 1/100” past the measured thickness.

FIGURE 7-29 Cutting Depths menu

EDIT PASSES

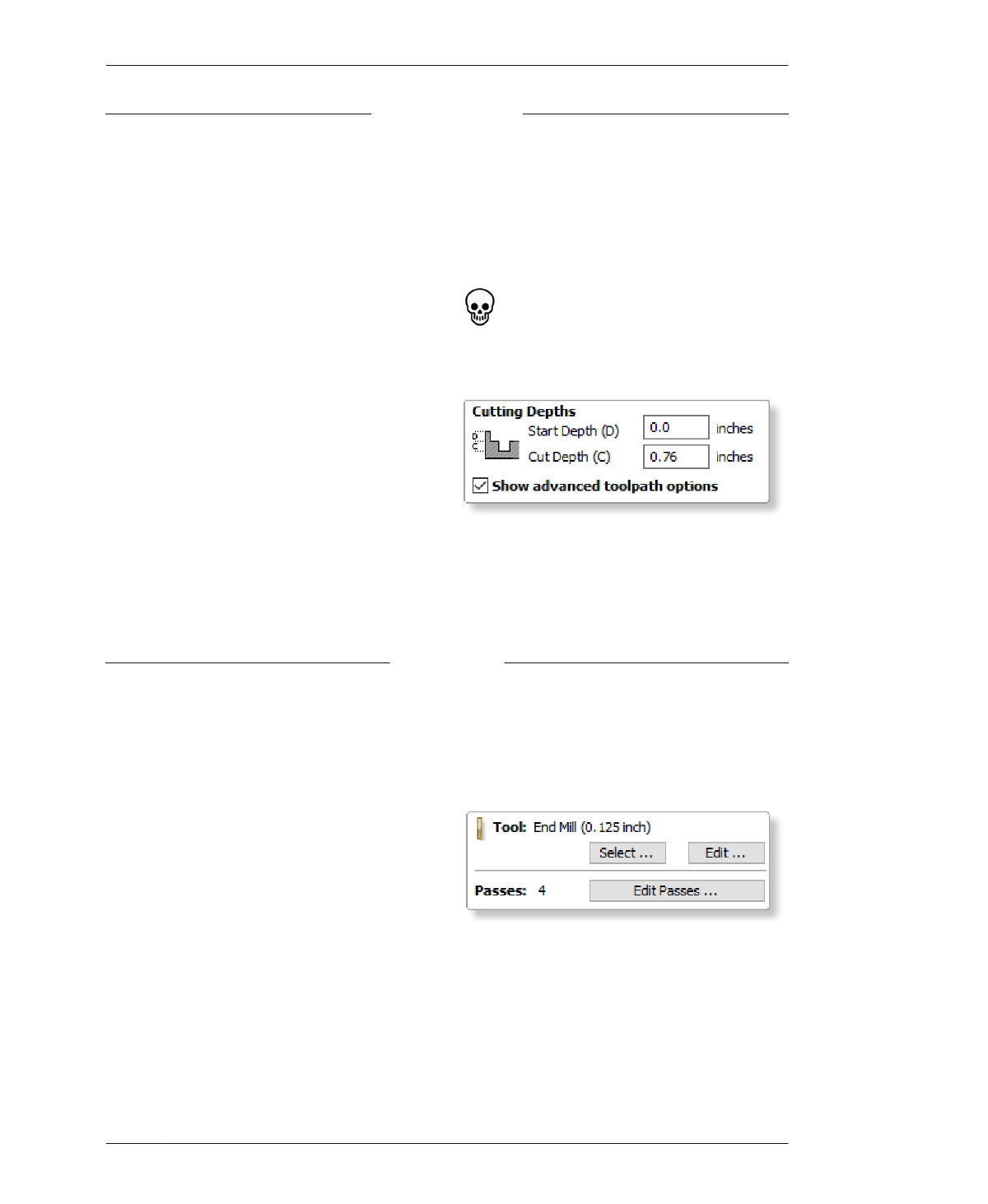

VCarve assigns a number of passes for the end

mill to cut through the material. Depending on

the thickness of your material and the size of

your end mill, multiple passes may be needed

to achieve the desired cut depth. Pass depth is

the vertical amount of material removed by

each small cut; their sum total is the cut depth.

Factors like material hardness, end-mill type,

edge quality, and desired cutting time deter-

mine the number of machine passes. In this

case, four passes will efficiently cut through ¾″

plywood, leaving edges that require only a light

sanding.

22A: Click the Edit Passes… button to open

the Edit Passes pop-up menu, changing the

Number of Passes at the bottom of the menu

to 4.

FIGURE 7-30 Tool Settings

07/MODELING SOFTWARE TO MACHINE

185