CREATING PROFILE TOOLPATHS FROM VECTORS

CREATING PROFILE TOOLPATHS

FROM VECTORS

Each profile toolpath has a unique combination

of cutting attributes. “Toolpaths” on page 44

explained how a tool could be programmed to

cut inside, outside, and on the vector. Depend-

ing on where the tool cuts, relative to the vec-

tor, the kerf shifts position, and, in turn,

changes the dimensions of the part.

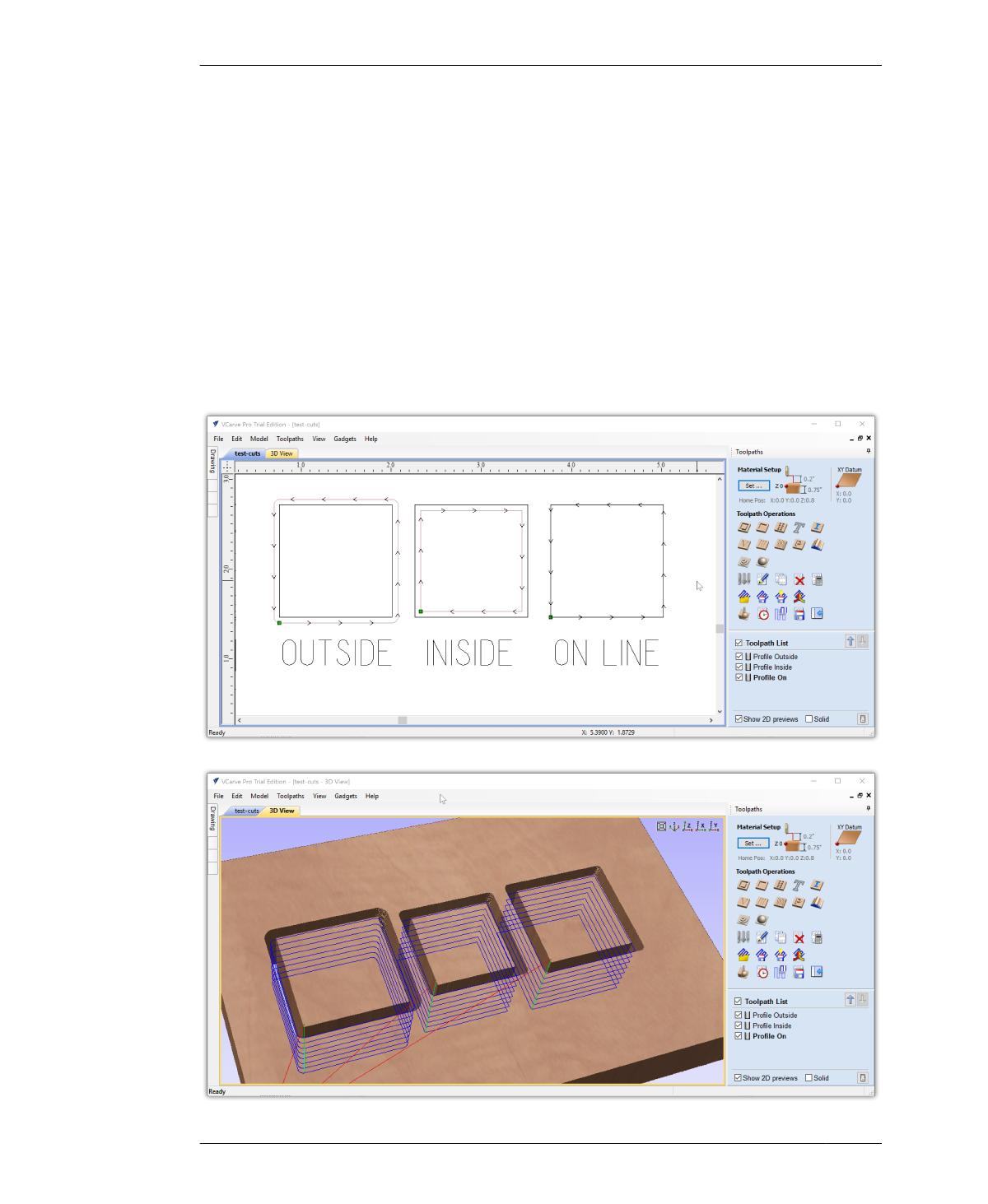

Before you create the toolpaths for the Rota-

tional Stools, take a look at Figure 7-22, which

contains three identical squares drawn with

identical dimensions. Each square is cut with a

1⁄8″ profile toolpath, each toolpath having a dif-

ferent relationshp to the drawn vector.

In Figure 7-22, the red line with black arrows

visually represents the path the tool will travel

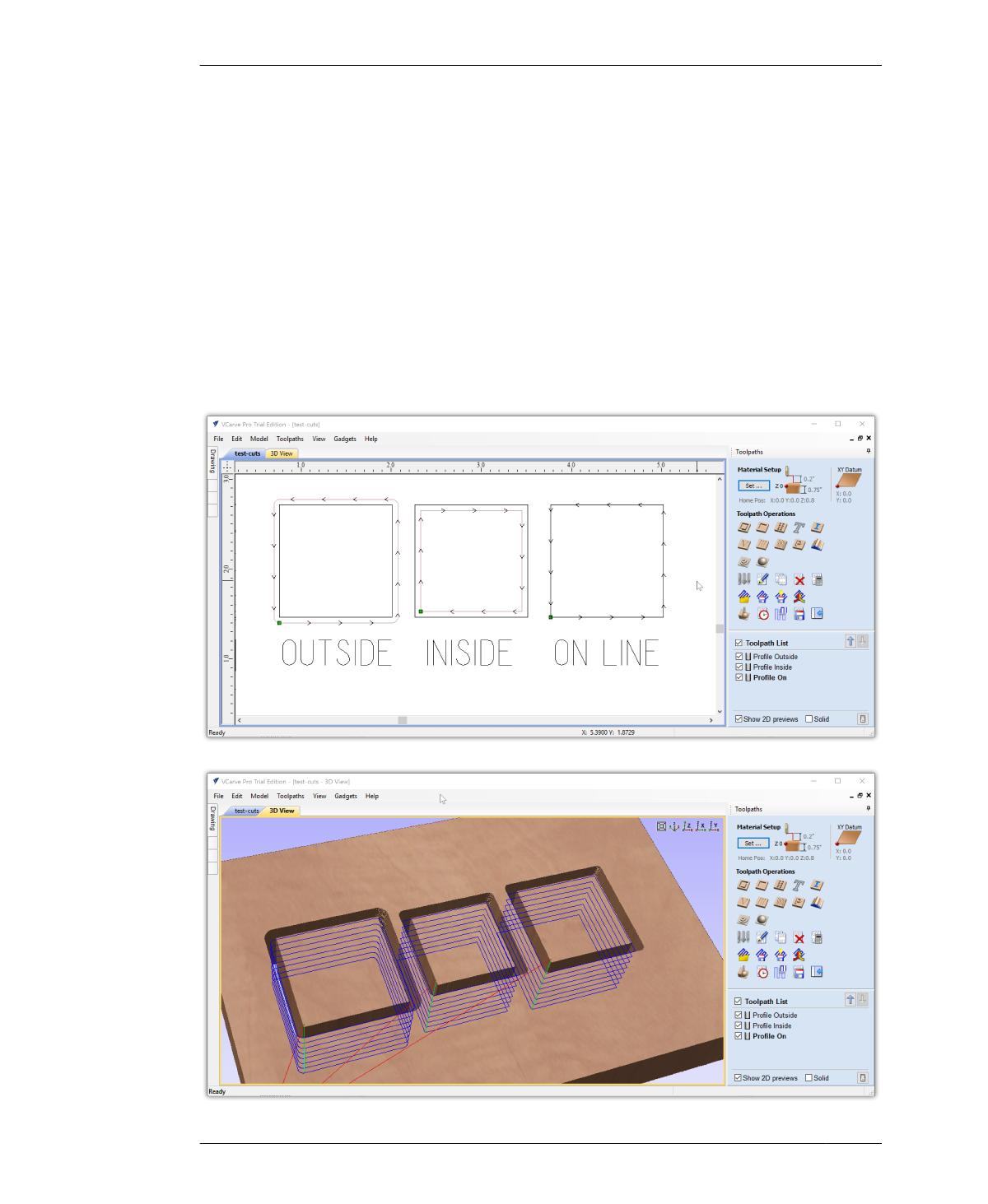

to machine the part. Figure 7-23 shows a 3D

machining simulation of the toolpaths.

FIGURE 7-22

The same size, equally

spaced boxes with out-

side, inside, and on line

profile toolpaths

applied

FIGURE 7-23

3D machining simula-

tion of outside, inside,

and on line toolpaths in

Figure 7-22

180

DESIGN FOR CNC