JOB SETUP

JOB SIZE

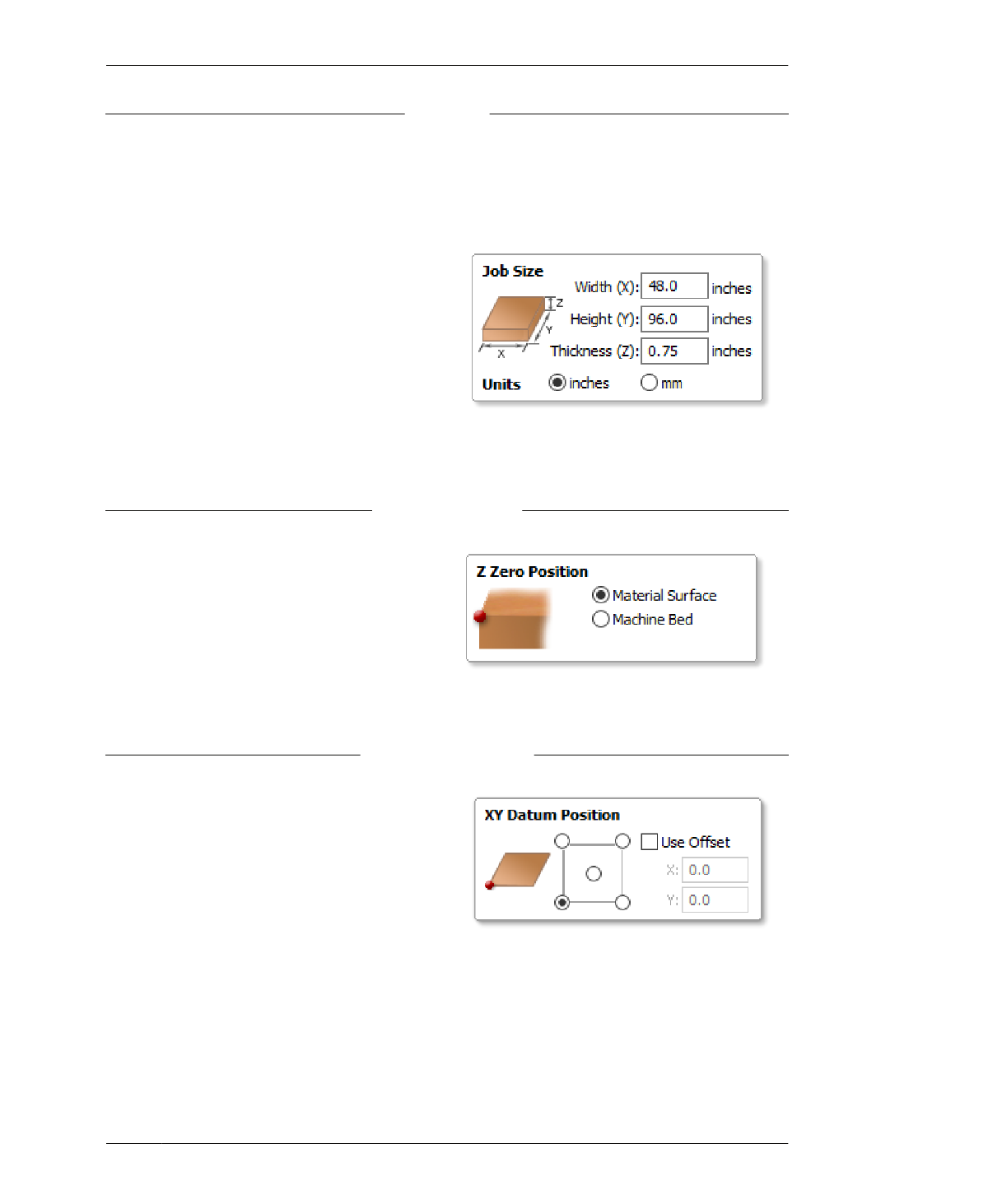

The Job Size matches the actual dimensions of

your material; this exercise uses a 4′ × 8′ × ¾″

plywood sheet. The units should match the

default units of your CNC machine. While Width

(X) and Height (Y) can be generalized, Thick-

ness (z) must be the actual measured thickness

of your sheet material, or TMAX from “Measure

Your Materials” on page 132.

the nominal value of 0.75 inches—in the Thick-

ness (z) field.

4C: Select inches, as shown in Figure 7-8.

4A: Enter 48.0 inches for Width (x) and 96.0

inches for Height (y), as shown in Figure 7-8.

4B: Enter TMAX in Thickness (z) field.

If you’re working through the exercise, without

plans to machine immediately, enter TNOM—

Z ZERO POSITION

FIGURE 7-8

Job Size

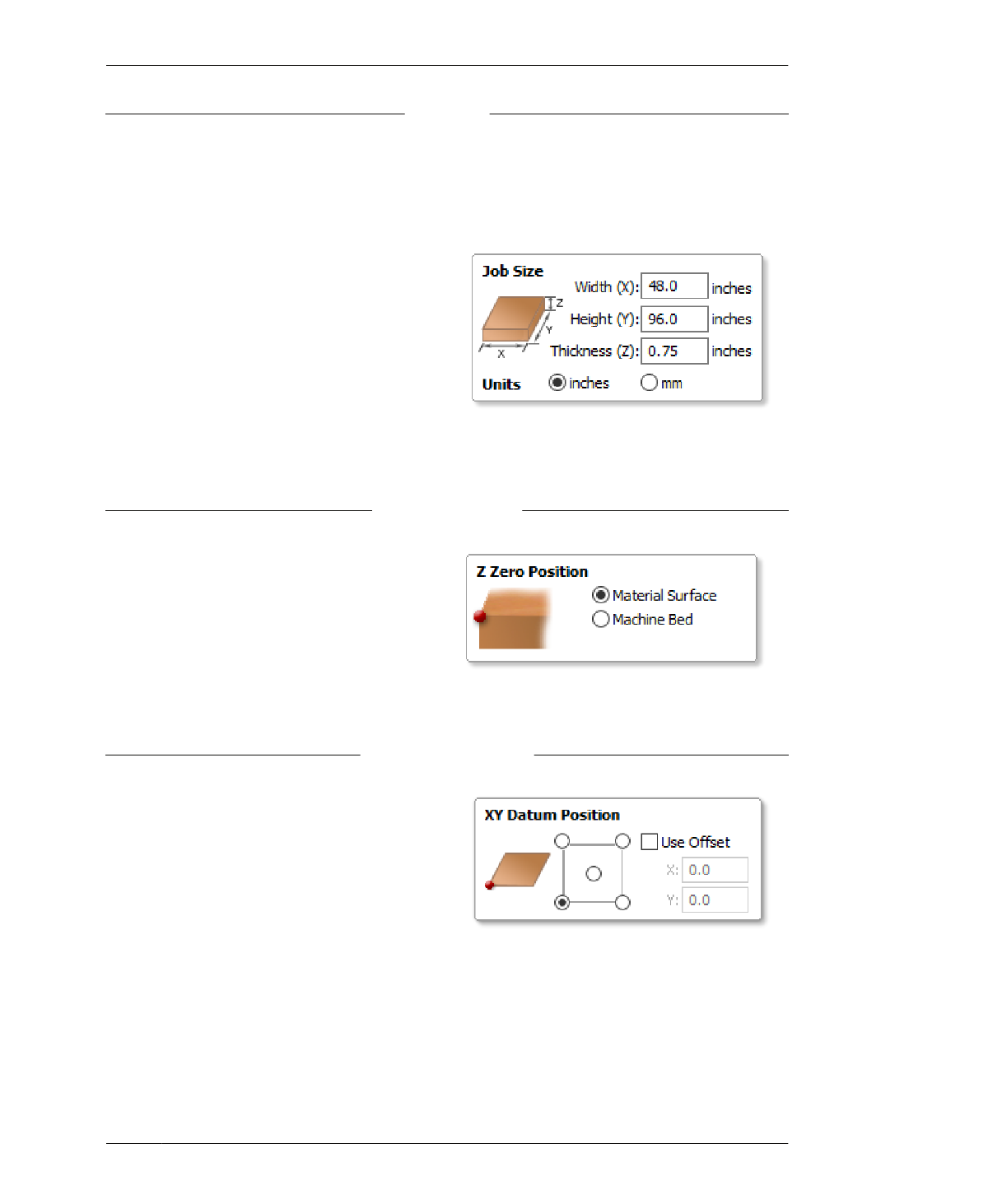

The default Z Zero option sets the z-axis origin

to the surface of the material. It’s also possible

to set Z Zero to the surface of the machine bed.

(“Pocket Cutting: Top Down or Bottom Up?” on

page 244 elaborates on why you would do this.)

5A: Keep the default Z Zero option selected

(Material Surface, as shown in Figure 7-9.

FIGURE 7-9

Z Zero Position

XY DATUM POSITION

A datum is a fixed starting point of scale or

operation. The datum position is intended to

correspond to the machine’s origin or (0,0),

which is usually set separately using machine-

specific control software, but can be offset in

CAM. Offsetting shifts the origin of your CAM

file by a specified (x,y) amount relative to the

machine bed size. Since the digital files you’re

using are mapped to a full sheet, you don’t

want to offset.

6A: Keep the default datum options selected,

shown in Figure 7-10 (unless your CNC is con-

figured differently); “Use offset” should be

unchecked.

07/MODELING SOFTWARE TO MACHINE

FIGURE 7-10

XY Datum Position

171