VCARVE PRO

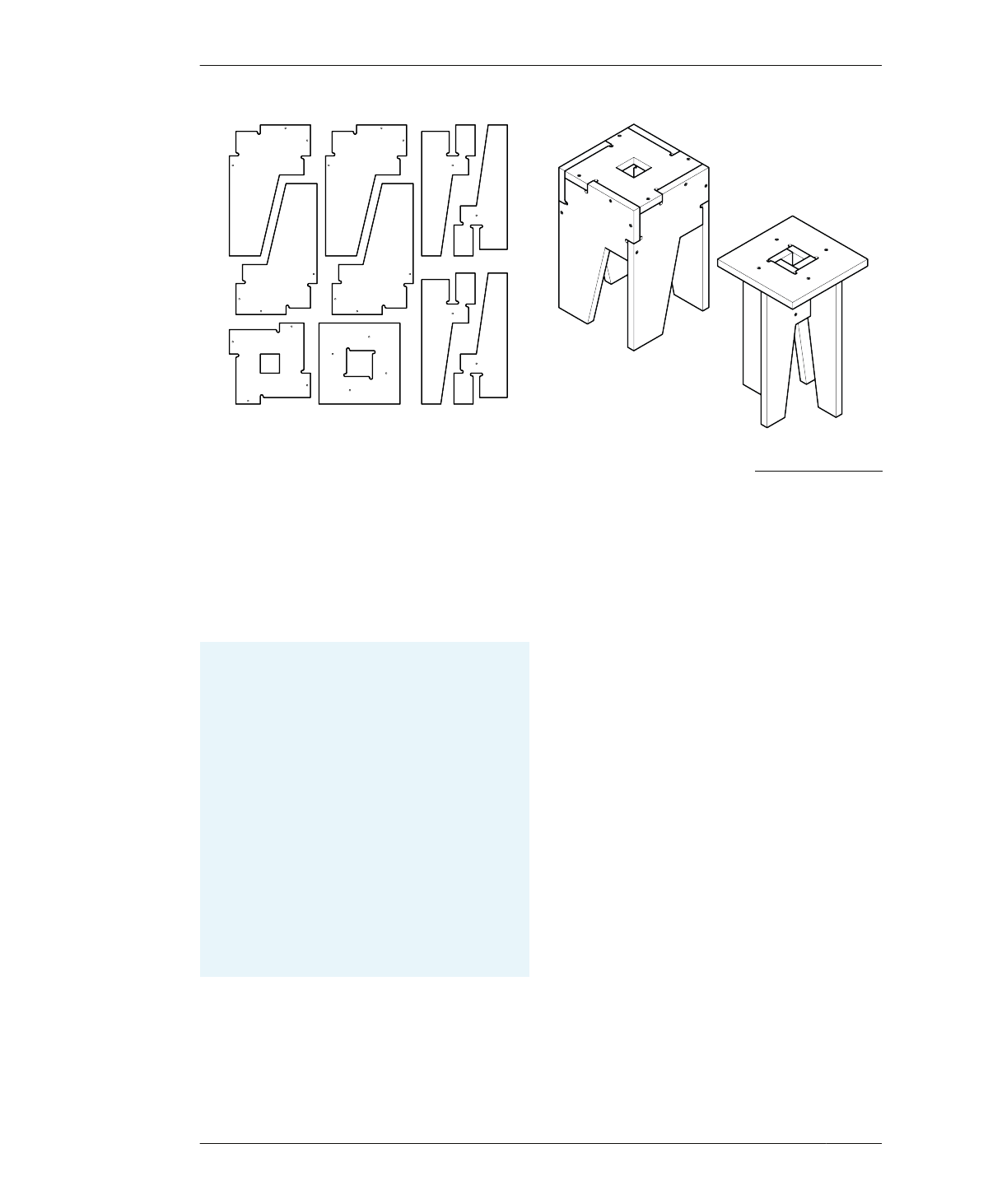

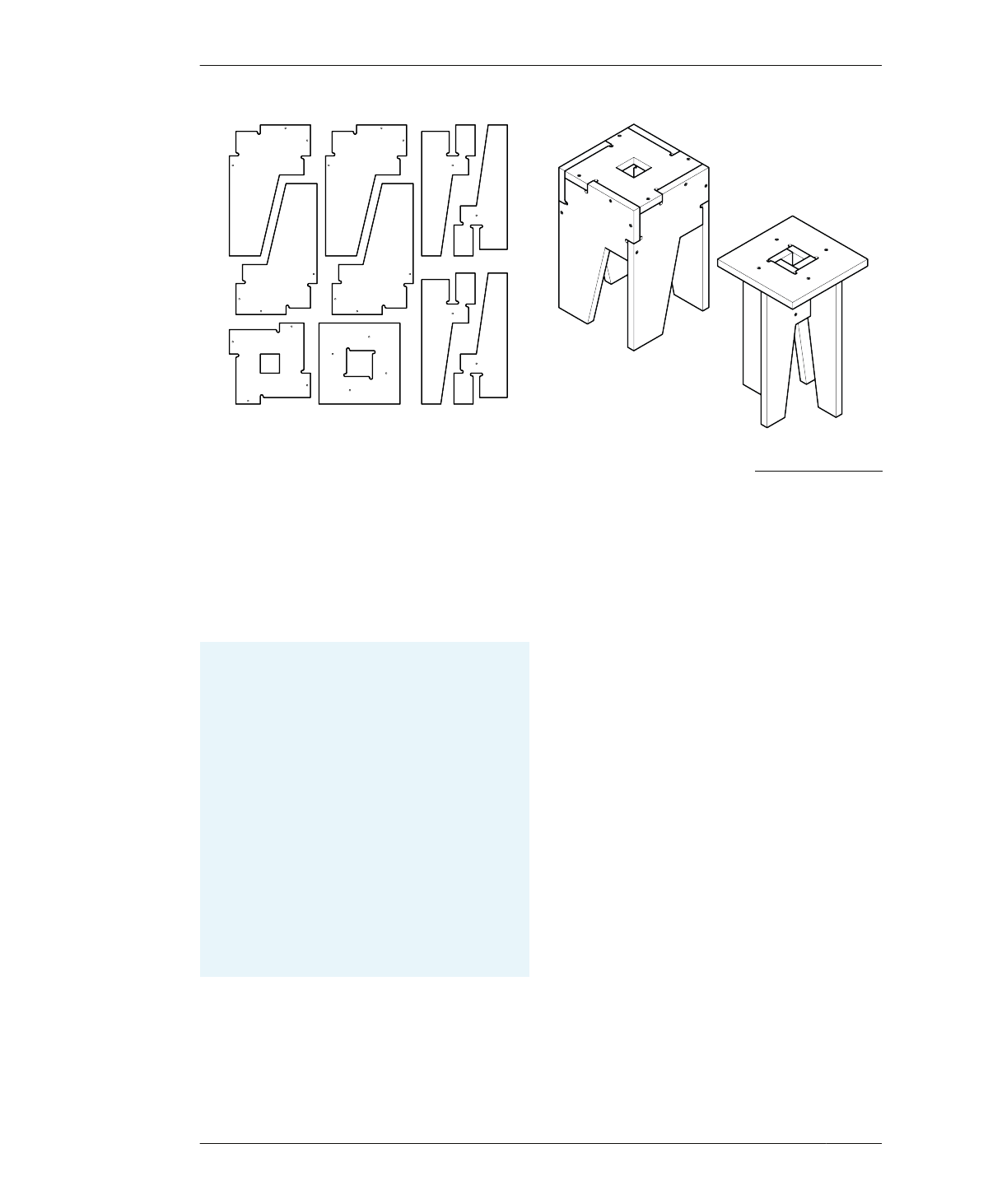

FIGURE 7-3

The Lazy and Lively

Rotational Stools and

vectors

you create to a physical machine. That’s com-

pletely fine for the purposes of this book,

because if you already have your own CNC—or

have access to one in a shared shop—that

machine will already have a CAM software tool-

chain in place. The toolpath creation principles

will remain the same, regardless of software.

CAM WORKAROUNDS FOR MAC OS

VCarve is only available for Windows machines, and

although times are changing, this is typical for CAM

software. If you are running Mac OS and you have

the hard disk space to install a copy of Windows, I

highly recommend Parallels (https://www.paral-

lels.com). In addition to creating CNC toolpaths, I

use it whenever I need to run CNC machines using

Windows- or Unix-flavored control software

machines from my Mac. You can also use Mac’s

built-in Boot Camp, Virtual Box, or another Windows

emulation program.

—Anna Kaziunas France

DOWNLOAD AND INSTALL

1A: If you don’t already have Vectric’s VCarve

CAD/CAM software, download and install a free

trial from the Vectric site (http://

www.vectric.com). For this project, you’ll need

the Rotational Stools (Figure 7-3) SketchUp file

(ATFAB_STL_D4CNC.skp), which can be found

on the book’s website (http://design-

forcnc.com).

This file, like all project files for this book, was

organized and saved as SketchUp 2014 using

the same process you followed in Chapter 3.

When you open the file in SketchUp, you’ll find

the 2D part profiles placed onto toolpathing lay-

ers, with individual parts and the overall cut file

grouped into SketchUp components. You’ll also

find a fully modeled version of the Rotational

Stools on 3D modeling layers.

Chapter 8 will walk you through the process of

fabricating the stool parts from your finished

CAM file. If you already have your material—

and want to fabricate the stools after complet-

ing this CAM setup exercise—you’ll need to

scale your CAD file to match your material’s

thickness (TMAX). Refer to “Measure Your

Materials” on page 132 and “Scale Your CAD

168

DESIGN FOR CNC