FROM CAD TO CAM

This chapter introduces CAM fundamentals,

walking you through file setup and toolpath cre-

ation in VCarve Pro, using the AtFAB Rotational

Stools SketchUp file. You’ll learn the principles

and practices of file setup, toolpath settings,

and machining simulation that are essential to

the pursuit of digital craftsmanship.

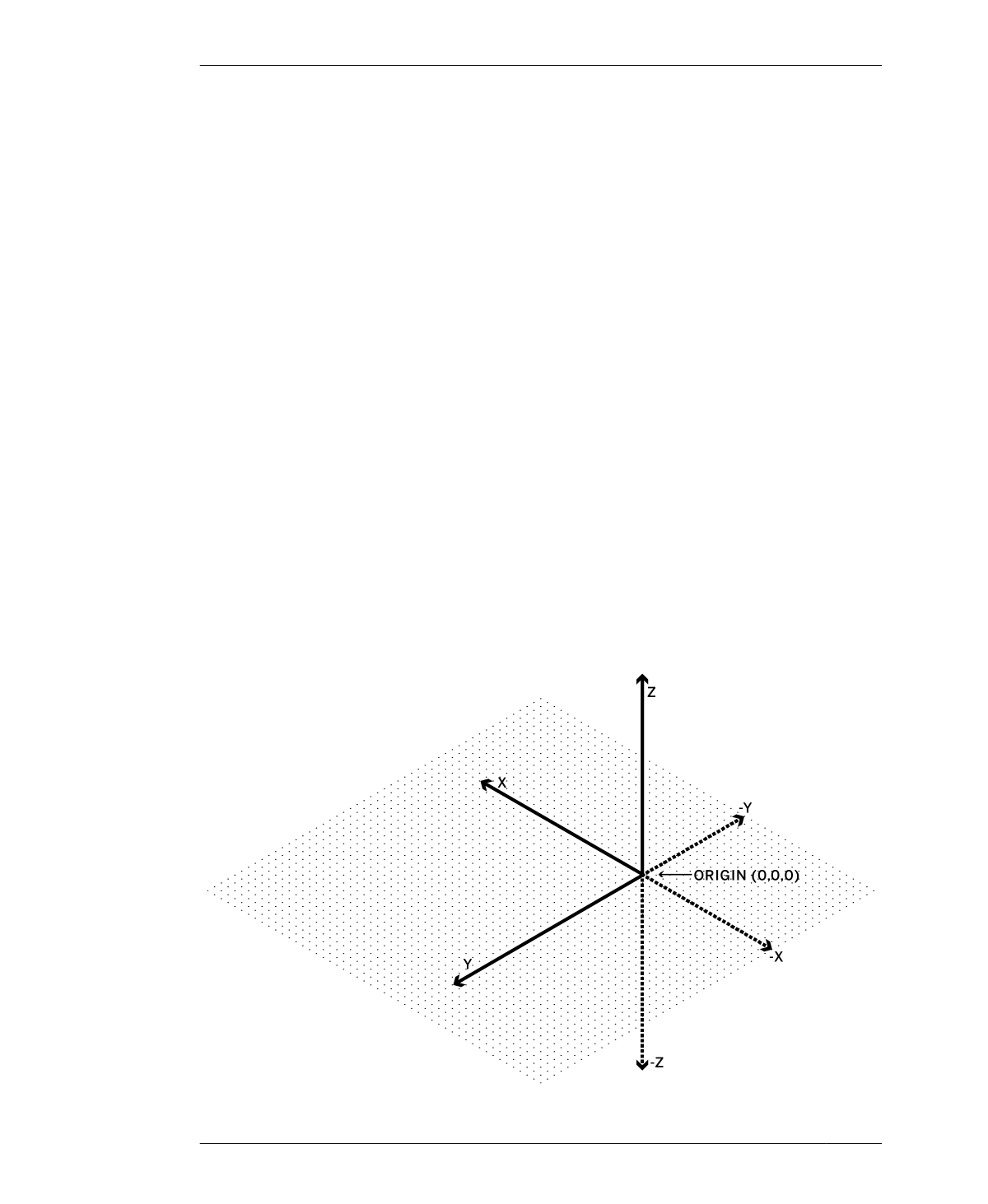

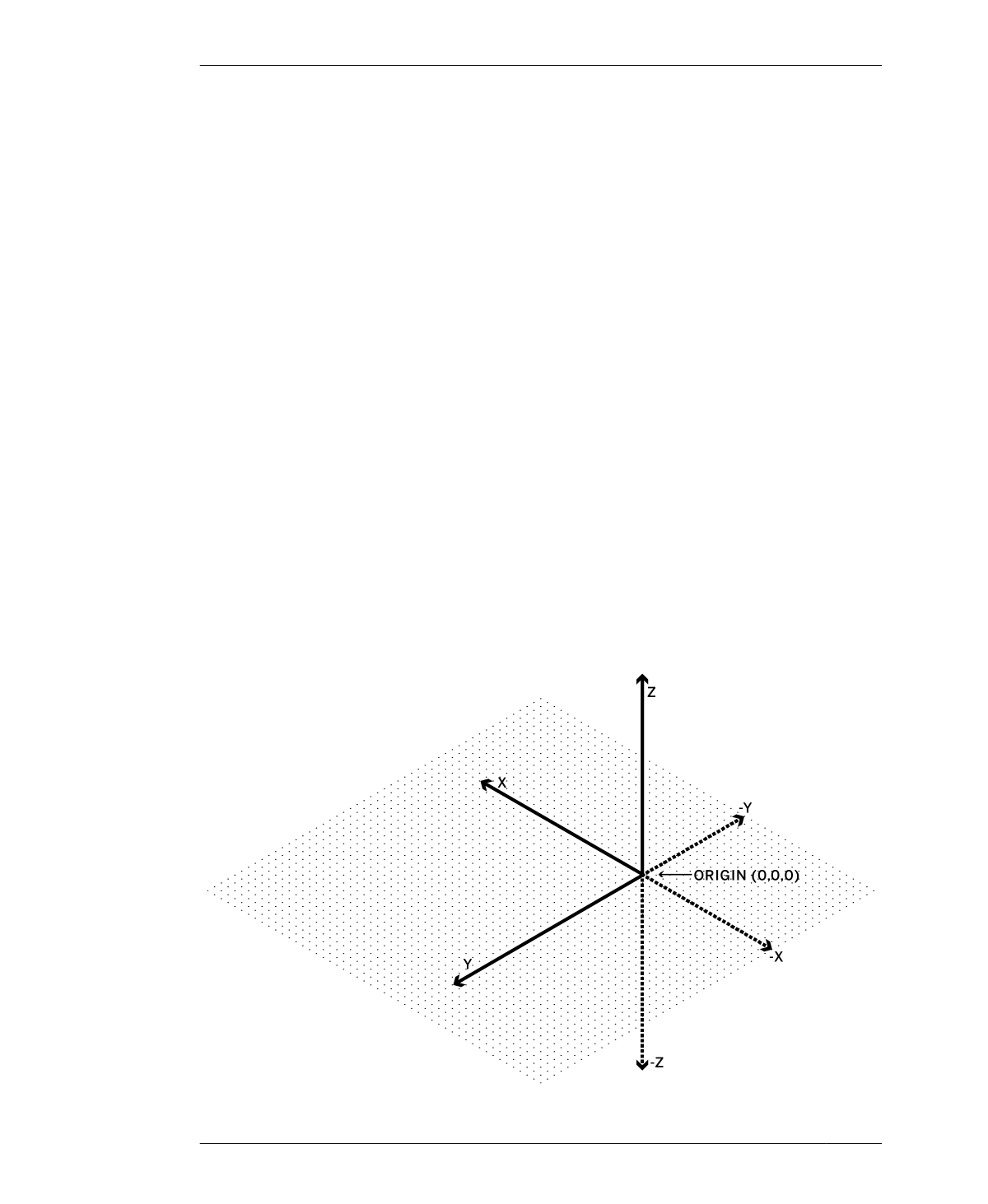

DIGITAL/PHYSICAL ALIGNMENT

Machining your files is exciting; your digital

dreams are about to become real objects! How-

ever, when the tidy virtual space meets reality,

things can get a little messy. CAM software is

where your digital “model space” meets the

physical properties of your machine and mate-

rial.

CAM programs are organized to help you man-

age the transition from digital file into reality.

Before you begin importing the digital informa-

tion, it’s critical to first identify the physicalities

of both your machine and your material. Know

the dimensions of your machine bed, as well as

the length, width, and thickness of your antici-

pated sheet material. It’s also key to locate the

XYZ origin (Figure 7-2) and orientation of the

machine bed, as well as its default units. With

these physical attributes identified, you are

ready to start setting up a CAM file that coordi-

nates physical machine and material with the

digital information in your CAD file.

UNITS

When you transition from designing to machin-

ing, you inevitably export and import files

across multiple programs. It’s a good practice

to pay attention to the unit settings in your file

and familiarize yourself with import/export set-

tings in your CAD and CAM software. Mixing

units can cause trouble with parts that scale to

the wrong dimensions or cause your machine

settings to go wildly off.

The digital/physical alignment process

becomes much clearer and easier once you’ve

become acquainted with the toolpath creation

FIGURE 7-1

Digital CAD file origin in

“model space”

166

DESIGN FOR CNC