POCKETS

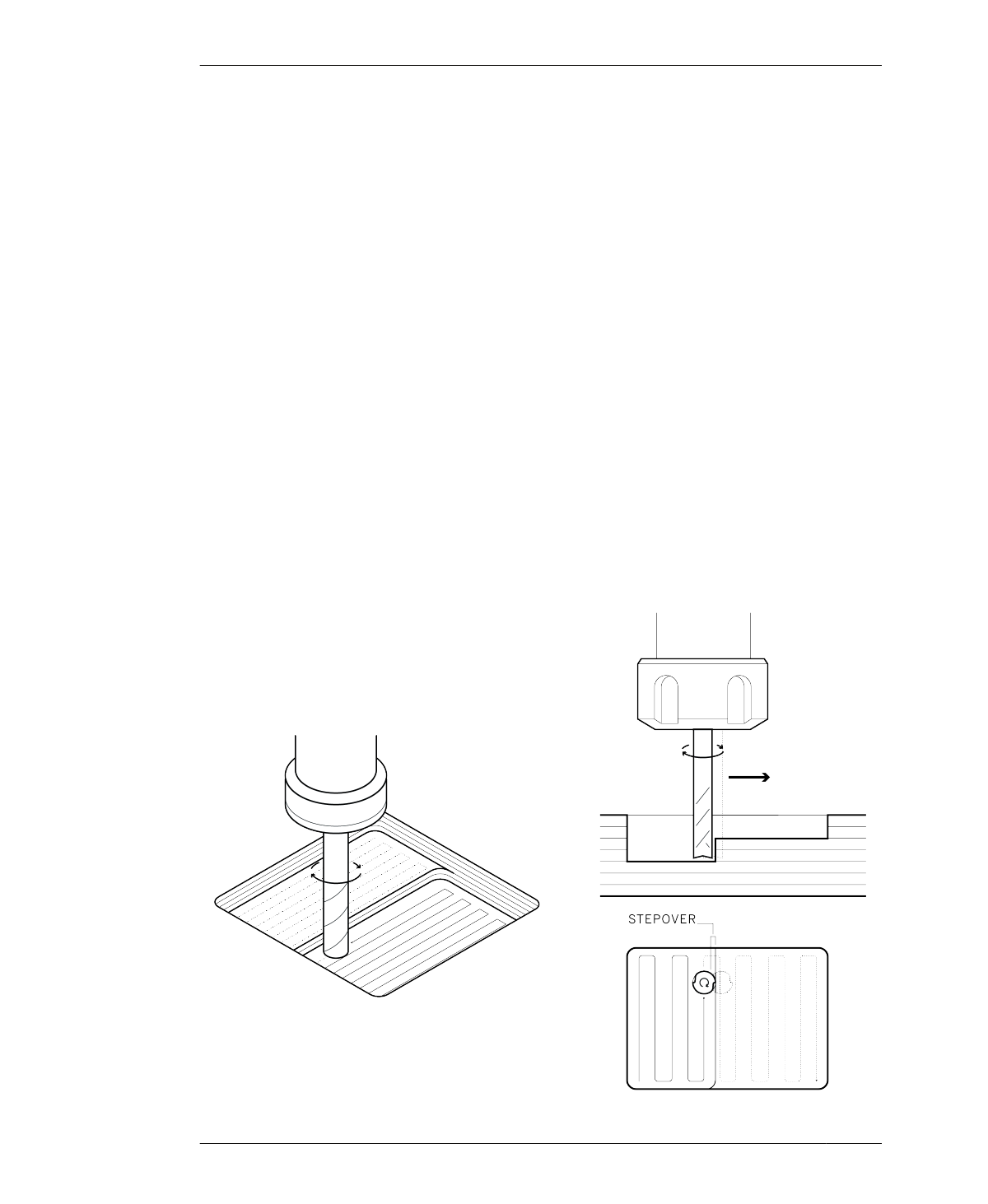

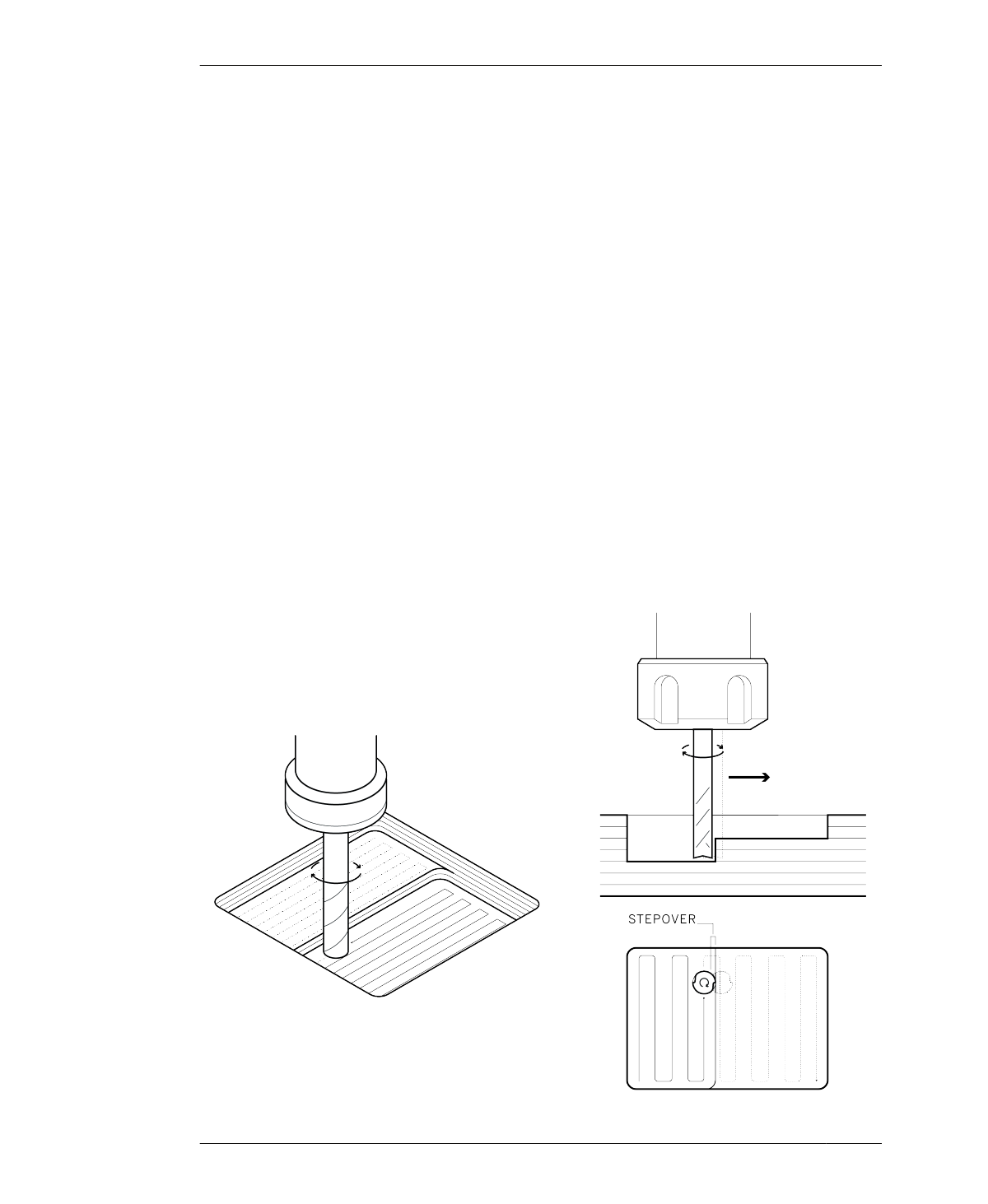

FIGURE 6-11

Multiple views of cut-

ting a pocket via the

raster method and

showing tool stepover

POCKETS

Pocket cuts have vertical sides and a flat bot-

tom and can be used to create a recessed area

for anything you can imagine, from joinery con-

nections to adornments. Pocket toolpaths are

similar to inside toolpaths; they both cut on the

inside of a closed line, but pockets also remove

all the material inside the cut line to a specified

cut depth.

If you’re familiar with the traditional hardwood

slot creation techniques of grooves, rabbets,

and dados, you can think of a pocket as the

“Swiss Army knife” of CNC slots. If you’re

attempting to translate a woodworking design

created by more traditional means for CNC

sheet goods, woodworking slots (grooves,

dados, and rabbets) are defined in terms of

how they run with or cut across the grain. How-

ever, because plywood is made from individual

sheets turned at right angles and glued

together, it doesn’t have a singular “grain” like

hardwoods do.

When clearing pockets, there are two basic

ways to remove the material: offset and raster.

OFFSET

Pockets cut using the offset method start at

the center of the pocket indentation and move

in a spiral pattern until the tool reaches the

pocket’s outside edge.

RASTER

A raster pocket begins at one end, and the tool

moves side to side from one end of the pocket

to the other, clearing out a recessed area, as

shown in Figure 6-11.

When pocketing visible designs or features,

rastering with the grain can help hide tool-

marks in wood. However, grain direction when

pocketing is more relevant when working with

158

DESIGN FOR CNC