RAMP MOVES AND TABS

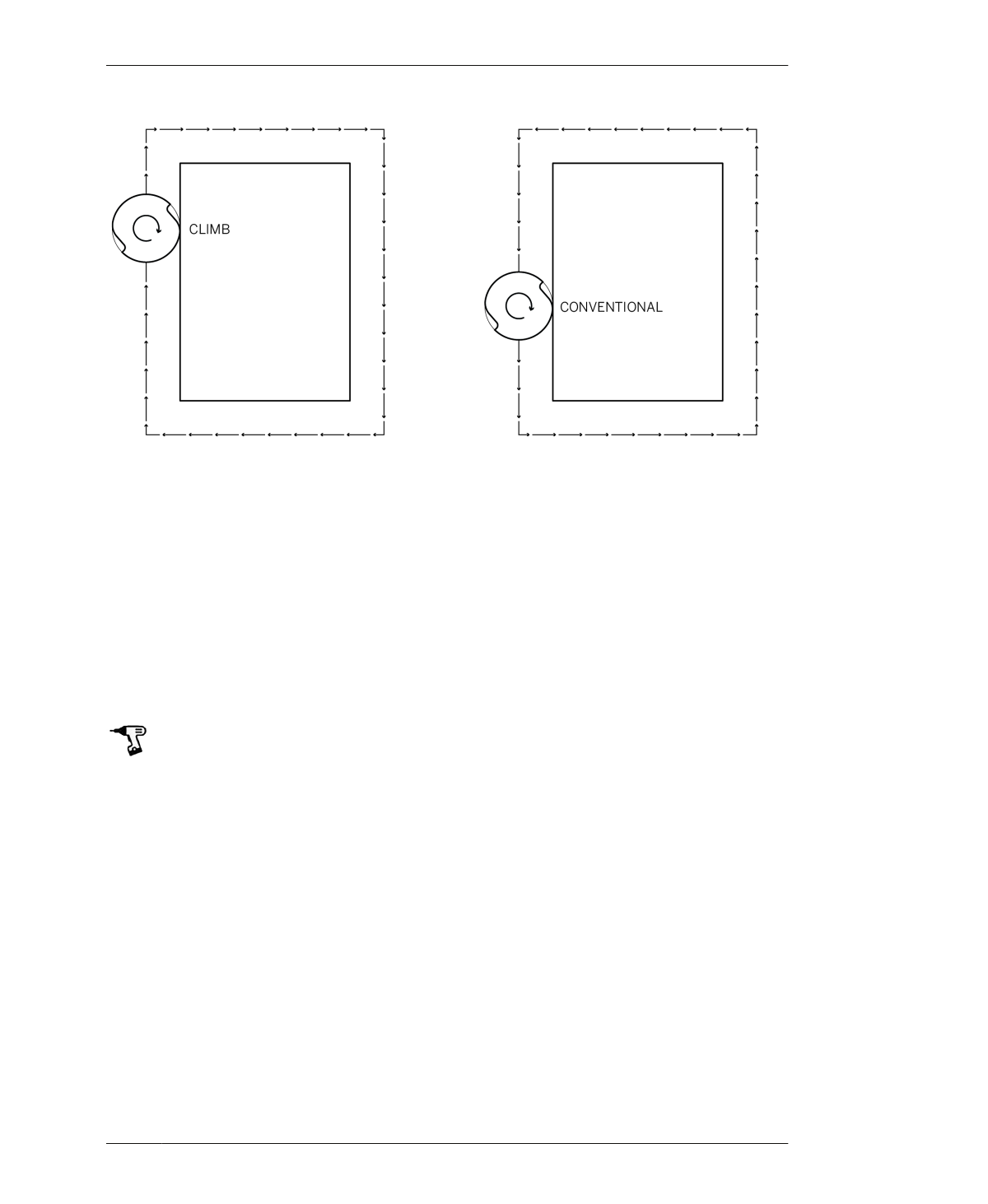

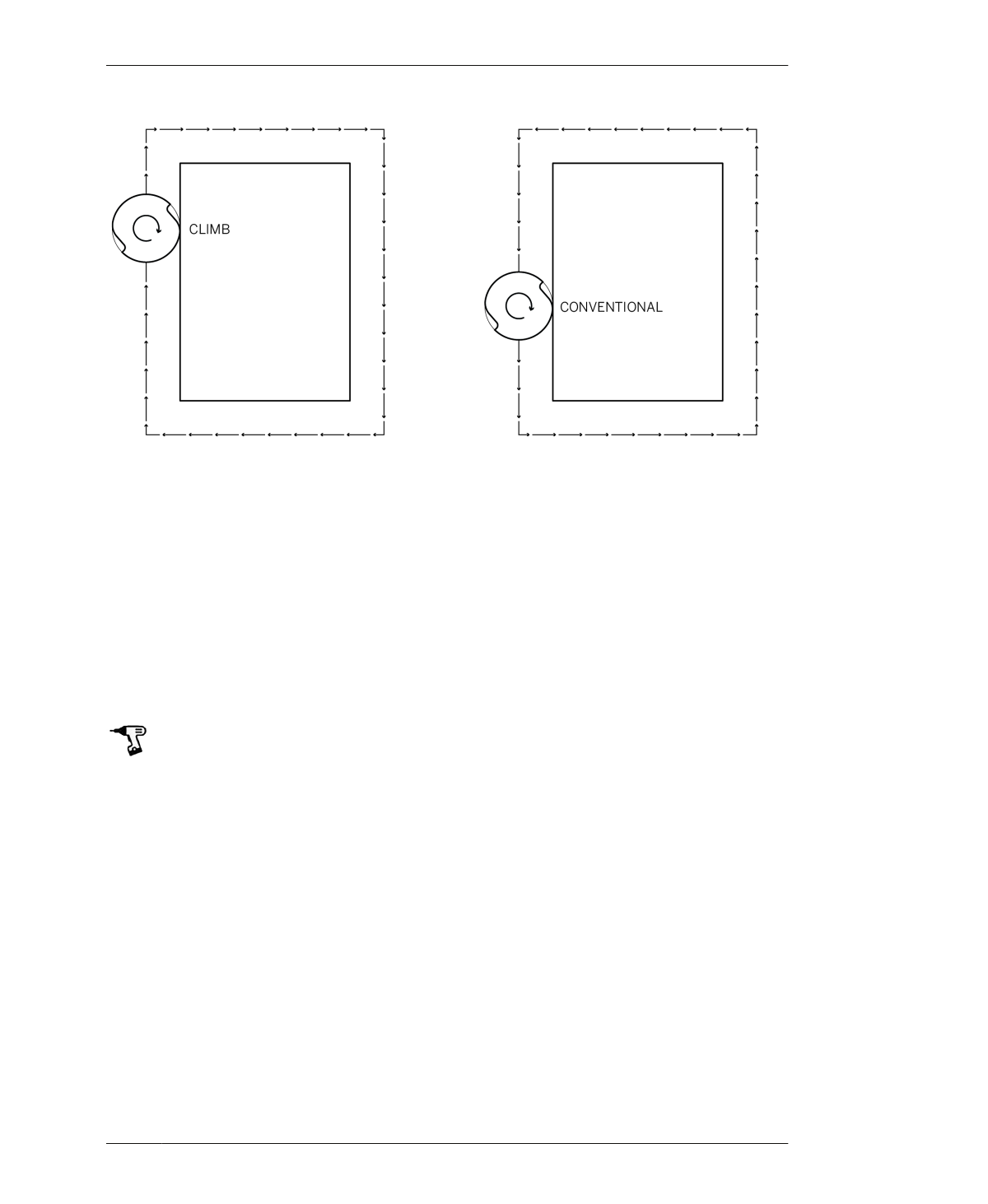

FIGURE 6-8

Climb versus conven-

tional

CLIMB CUTTING

In a climb cut, the chip starts thick and ends

thin. This can result in a smoother cut in mate-

rials such as hardwood because it eliminates

end-grain splintering. However, the forces cre-

ated can also mar the finsh and push parts

around due to the bit trying to “climb” out of

the cut. In addition, the forces created can

deflect the tool.

Conventional (counterclockwise) and climb

(clockwise) feed directions are reversed when

pocketing or cutting the interior of a part.

When making interior cuts, a conventional

feed direction will move clockwise, and a

climb cut will move counterclockwise.

FEED DIRECTION STRATEGIES

Although we’re recommending a conventional

cut for plywood, this isn’t gospel. Machining

advice is always specific to the exact materials

and tooling you’re using. Plywood varies greatly

between brands, types, and even between

batches. Sometimes climb cutting may work

better than conventional.

The key is to jump in and test your material/

tool pairing and settings. Always cut in the

direction that gives you the best finish. Cut

some test pieces and look at both the part and

the scrap/waste material. If the scrap looks

better than your cut parts, reverse the feed

direction.

You can also try using an onion-skin strategy.

This is a machining methodology that utilizes

the strengths of both climb and conventional

cutting. First, climb-cut the part, but leave a

thin “onion skin” layer behind. Then cut the

final pass as a conventional cut. 1

RAMP MOVES AND TABS

Although center-cutting end mills can plunge

straight into the workpiece when beginning a

toolpath, it’s hard on the cutter and leads to

premature wear—while it is possible to drive

them axially into your workpiece that doesn’t

mean you should.

Ramp moves are a much gentler way to ease

the tool into the material. Ramping in at a grad-

ual angle reduces heat buildup and spindle/z-

1. Router Bit Basics for

CNC by Steve Glassel

describes the process in

detail, see Appendix A.

06/MACHINING FOR DESIGNERS

155