END-MILL GEOMETRIES

angles and depths, depending upon your

desired depth and width of cut.

Engraving

Engraving tools make a shallow cut along a

toolpath. They are capable of etching very fine,

often decorative, details into a surface.

FLUTE TYPES

End mills for machining wood have radial or

helical flutes. Radial flutes are straight grooves

that are parallel to the tool’s axis, while helical

flutes wrap around the tool.

Higher helix angles clear chips away from the

cutting edge faster. Straight tooling with radial

flutes have a 0° helix angle, while spirals for

cutting wood can have a helix angle of up to 35°.

In addition to high helix angles, router bits also

have steeper rake (tool attack angle) and clear-

ance angles to evacuate the chips much faster

than a traditional end mill.

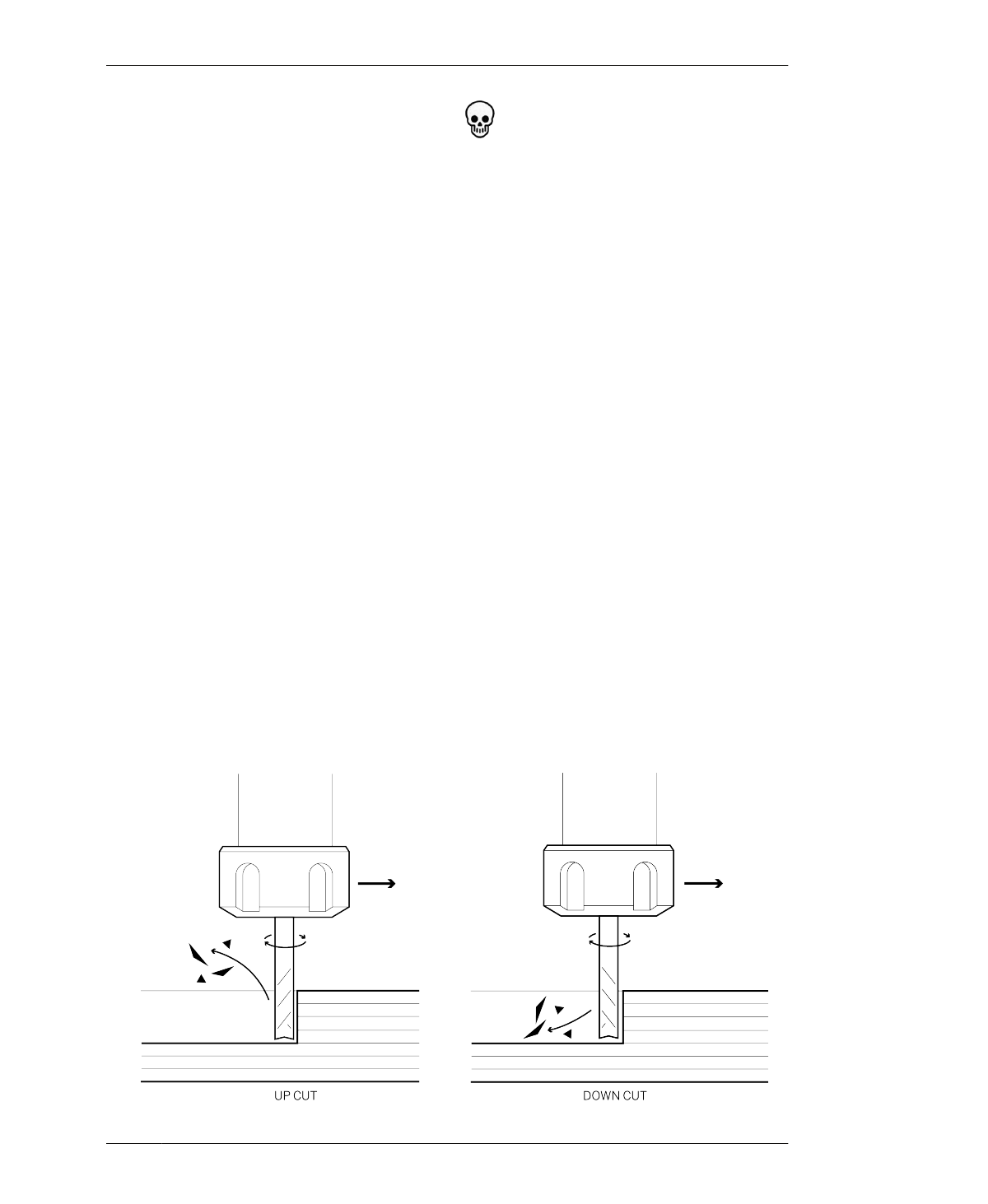

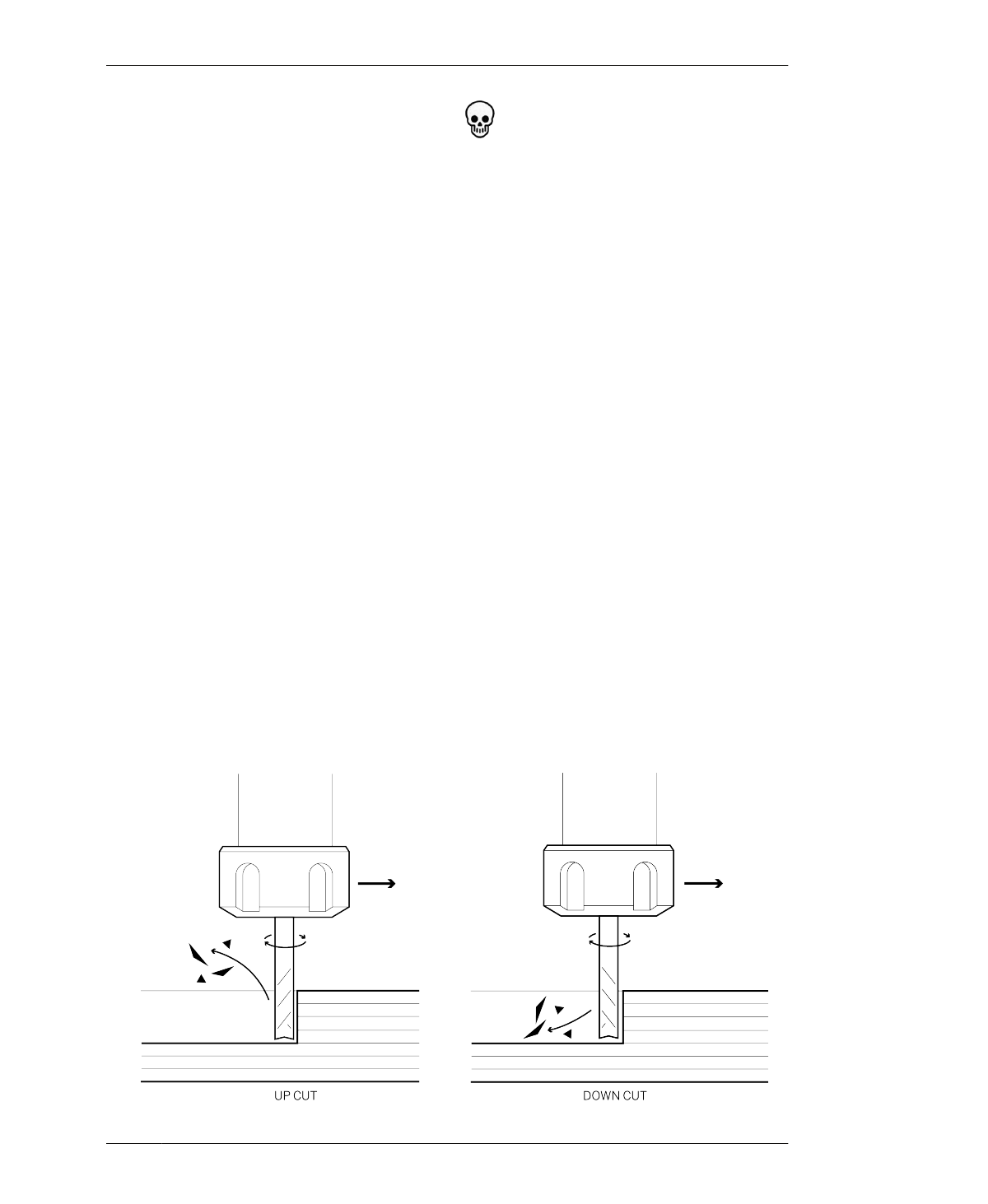

As the tool turns, the direction of the spiral

determines which way chips are ejected. The

two basic types of helical end mills are upcut

and downcut, shown in Figure 6-7.

Stay away from left-hand rotation tools, often

indicated with an “L” or “LH” in the tool num-

ber. They are meant for spindles that rotate

counterclockwise.

Upcut Spiral

This tool’s flutes eject chips upward, out of the

gap created between the cut piece and the

waste material (kerf). Because the chips are

forced up, the material’s top surface can

become chipped or frayed (known as tearout),

while the bottom face will be cleanly cut.

Although upcut tools are very efficient at dissi-

pating heat and clearing chips, they have some

undesirable effects that can make them a poor

choice for routing plywood. The upward chip

movement pulls the material up from the cut-

ting bed, creating a troublesome lifting effect

on lighter, thinner materials. This movement

can also pull at small cut parts and long skinny

parts. This can be problematic for vacuum hol-

downs, and you’ll need to use tabs to keep

parts in place.

Downcut Spiral

A downcut spiral’s flutes push chips downward,

toward the machine bed. When cutting with ¼″

FIGURE 6-7

An upcut tool pushes

chips up and out, while

a downcut tool forces

them down into the

kerf, as it cuts

06/MACHINING FOR DESIGNERS

153