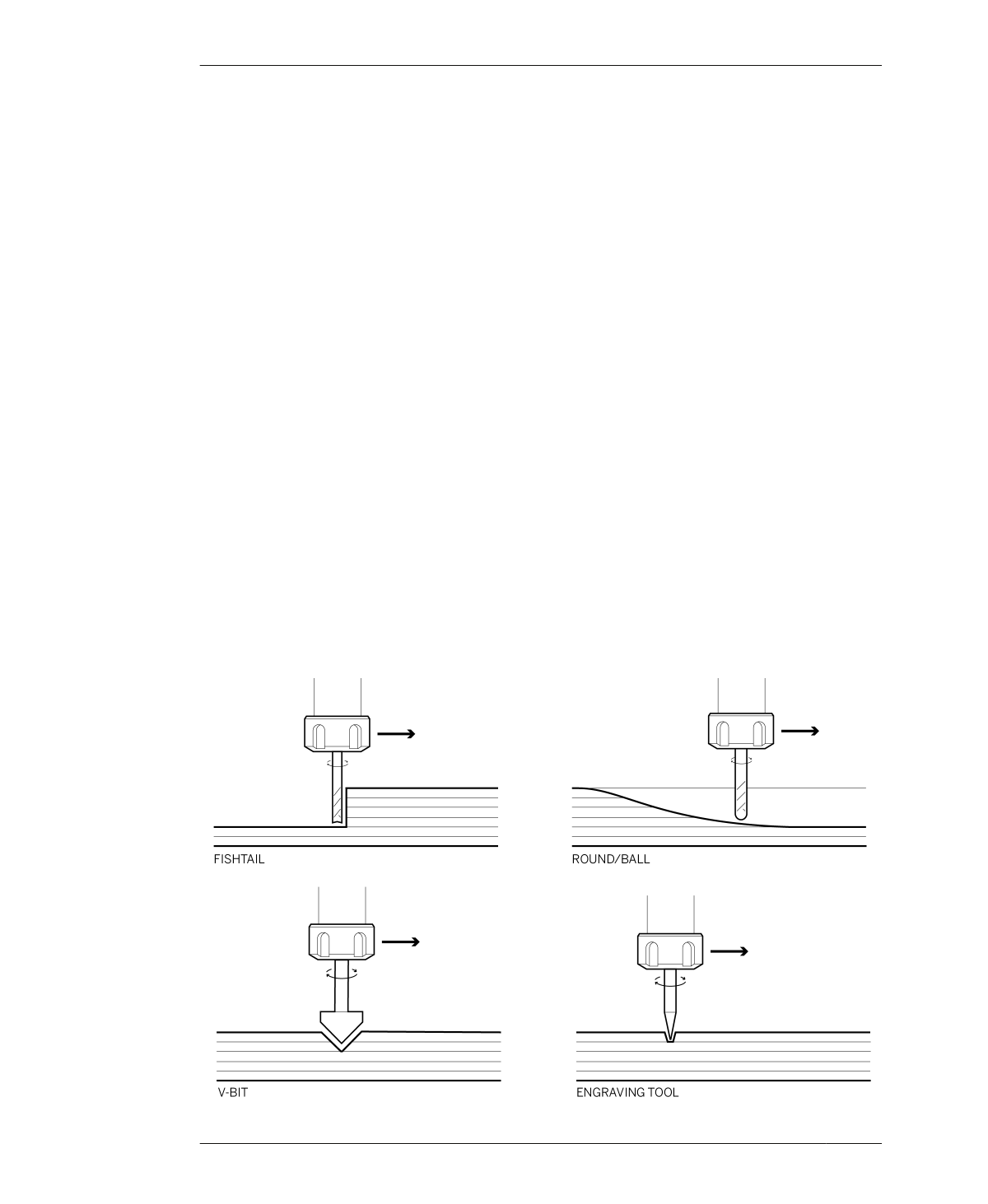

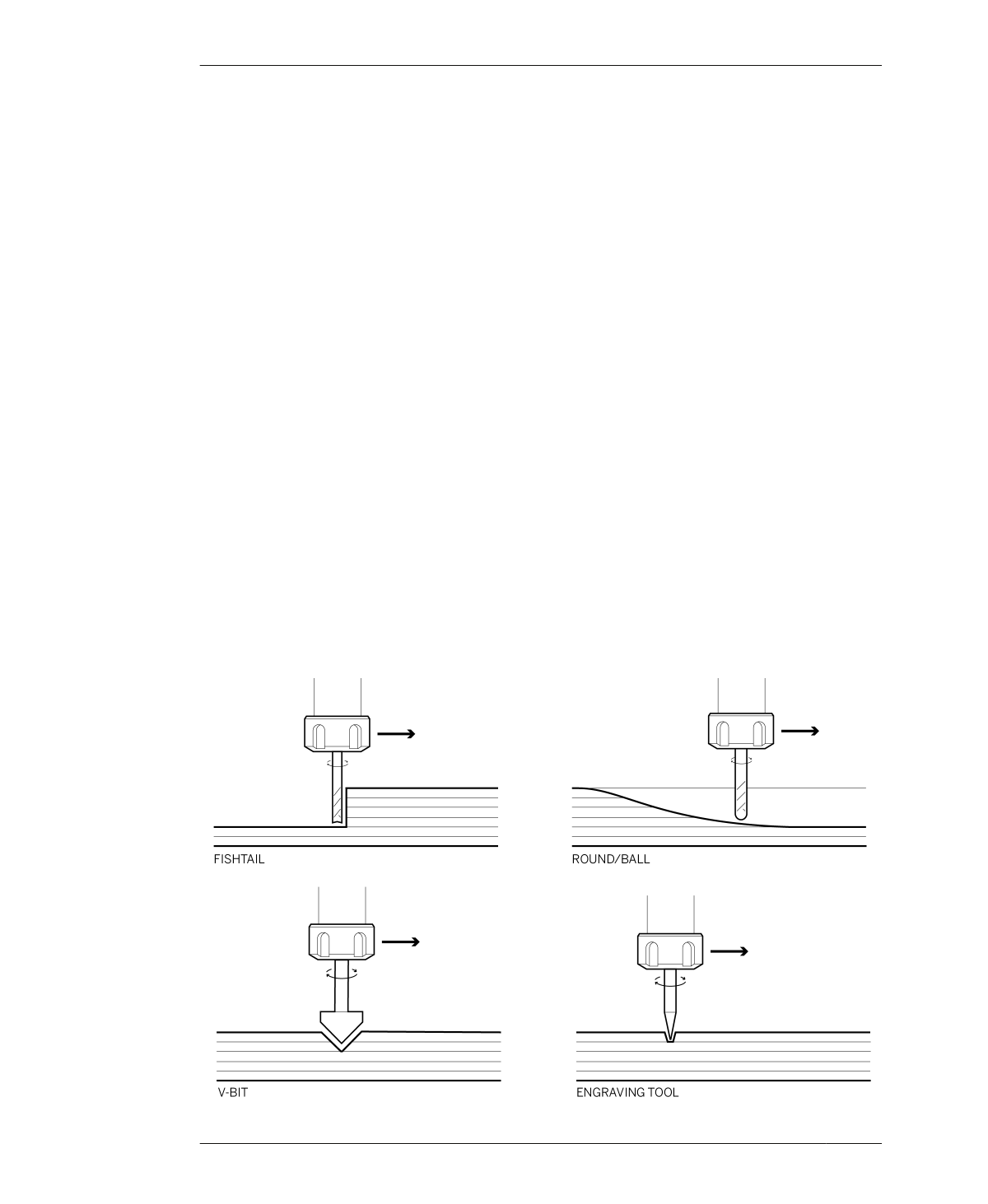

FIGURE 6-6

Tool end types

END-MILL GEOMETRIES

END-MILL GEOMETRIES

Pairing your material and machine setup with

the proper tool is vital, but it can be a challenge;

there are an immense variety of cutter types

and shapes available for every conceivable

material and cut type. But don’t worry, we’ll

walk you through the basic principles and tool

types—and provide tool recommendations for

routing plywood with part numbers and suppli-

ers to get you started.

END TYPES

End mills for machining wood have two basic

end types: those that are able to plunge

straight into material, and those with flattened

end flutes that must be ramped in.

Standard/Plunge End

These tools are sometimes called fishtail or

swallow tail end mills, due to the indentation at

the end of the tool. These tools work well for

both profile and pocket cutting. For profile cuts,

it produces a completely flat edge surface. For

pockets, it leaves a clean, 90-degree angle

between the side and the bottom, and gives the

bottom of the pocket a flat surface (for further

details, see “Pockets” on page 158).

Finish/Flat End

The fishtail-style plunge end mill can leave tool-

mark scratches in the bottom of a pocket,

which can be eliminated by using a finish or flat

end mill (FEM), which must be ramped into the

cut due to its much flatter end.

Ball-nose

A ball-nose end mill has helical flutes and a

round end, which is best for contour cutting,

and is capable of creating topographic smooth-

ness because its ball end makes minimal con-

tact with curved surfaces.

V-Bit

A v-bit has an angled tip that carves a deep v-

shaped groove into the material surface. Typi-

cally the sharp bottom of a v-bit is aligned with

the toolpath, making it ideal for v-carving, or

cutting decorative details with a three-

dimensional effect without the need for an

actual 3D model. V-bits come in a variety of

152

DESIGN FOR CNC