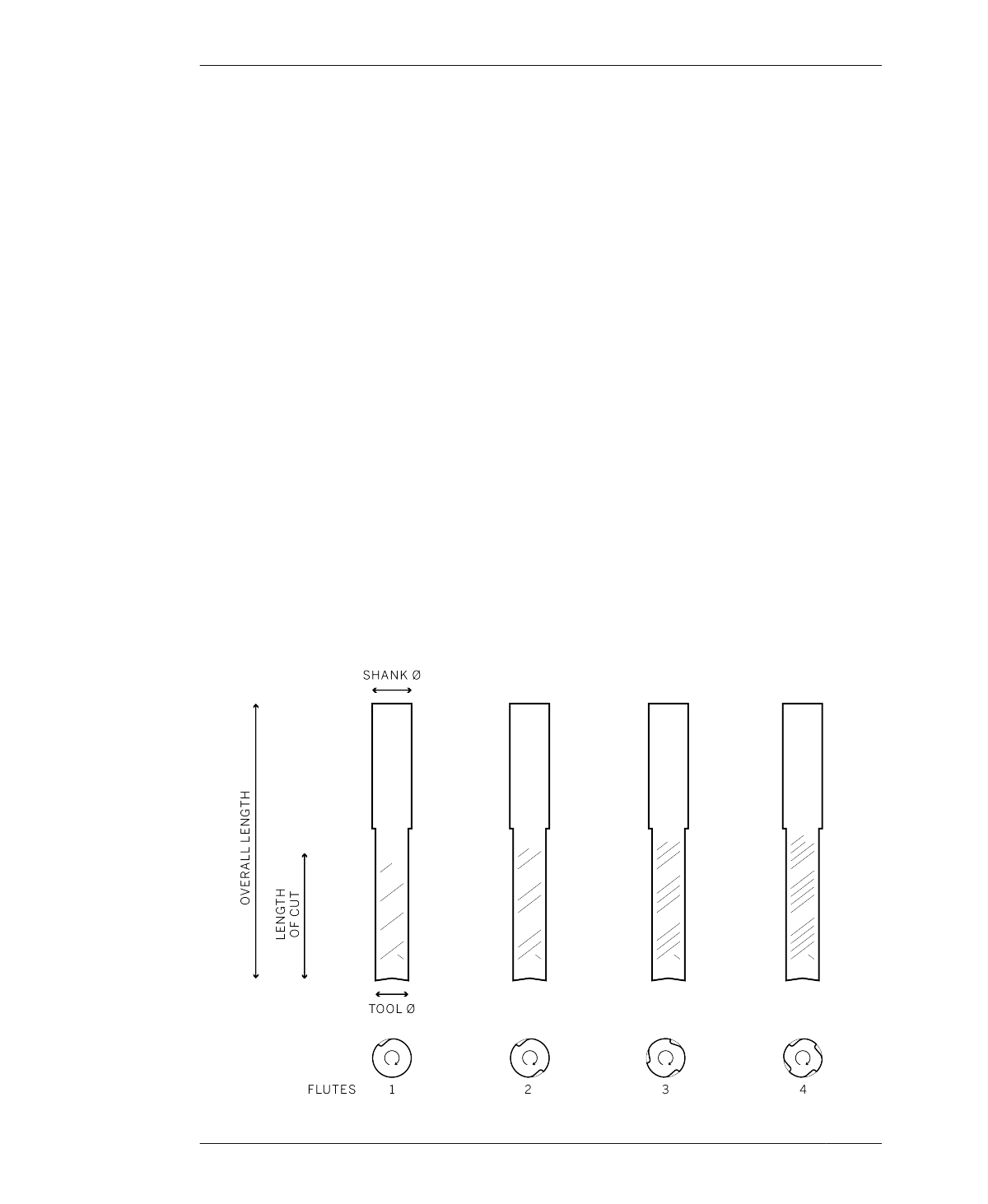

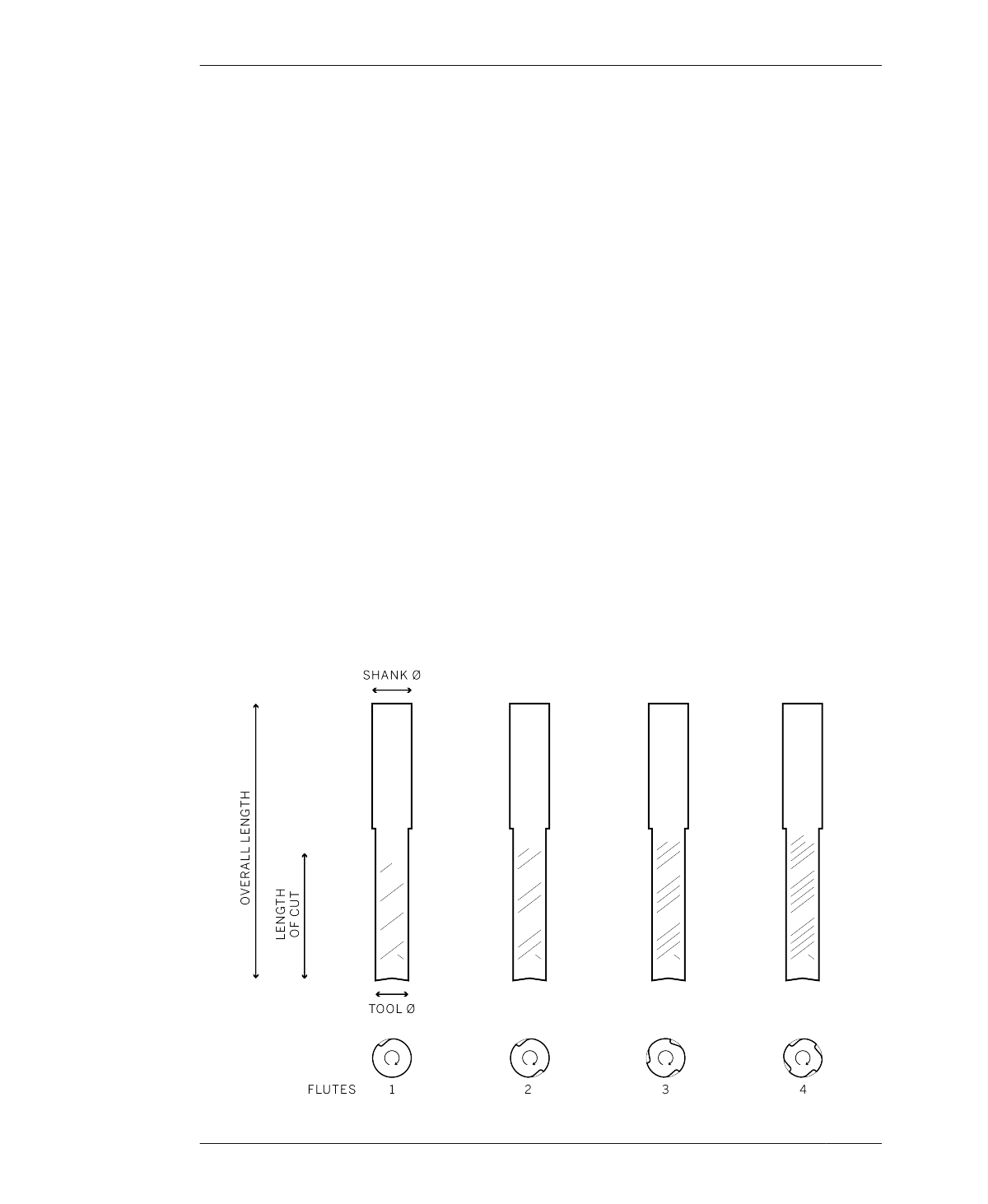

END-MILL ANATOMY

END-MILL ANATOMY

A router bit is a type of end mill. These terms

are more or less interchangeable, but there are

individual attributes that make a tool optimized

for cutting a specific material.

The term end mill has a milling/machinist ori-

gin, and mills existed long before there were

routers. Because routers and high-speed spin-

dles spin at dramatically higher RPM than tradi-

tional mill spindles, machinists created

modified end mills for routing wood without

burning it up and starting a fire. These mills

were capable of cutting at higher spindle

speeds, and were subsequently dubbed router

bits.

Fortunately, both end mills and router bits

share common anatomical features, so know-

ing their parts will help you focus on the fea-

tures that most impact your project.

Tool Materials

End mills come in a variety of materials. Tools

made of solid carbide are more expensive, but

yield the best finish, have the longest life, cut

quickly through material, and plunge well. Less

expensive carbide-tipped and high-speed steel

(HSS) tools tend not to perform as well and

prove to be less durable.

Flute

The radial or helical grooves machined into a

tool. Each flute has a sharp cutting edge (or

tooth) that cuts and then evacuates chips. End

mills with one, two, or three flutes are used in

woodworking, with two flutes being the most

common. Tools with four or more flutes are typ-

ically used to mill harder substances.

Shank

The plain region without flutes that is inserted

into the spindle. Shank diameters come in

standard sizes, the most common are: ¼″, ½″,

and 1⁄8″.

FIGURE 6-5

Key parts of an end mill

150

DESIGN FOR CNC