MACHINING VARIABLES

MACHINING VARIABLES

Each material has a range of workable spindle

speeds. For example, spindle speed for routing

plywood is somewhere between 11,000–18,000

RPM. But speed is only one of several variables

in the feeds and speeds equation that deter-

mines how the tool, material, spindle speed,

and tool movement through the material, or

feed, work together to make a cut.

Knowing the optimal spindle speed range for

plywood is helpful, but how do you determine

the exact spindle speed to use?

Speed

Spindle speed, measured in revolutions per

minute (RPM) is calculated from a combination

of specific aspects of cutter geometry, feed

rate, and chip load:

RPM =

FeedRate

NumberOfFlutes × ChipLoad

Feed Rate

Feed rate is the velocity at which the tool moves

laterally through material. Feed rate is meas-

ured in distance per time, or inches per minute,

and abbreviated IPM 1:

RELATING EVERYTHING TO

EVERYTHING

Feeds, speeds, and chip load are machining’s

trinity. They can be defined separately, but

when cutting, all three work together simulta-

neously to produce chips.

When trying to grasp a concept, always look at

how it is measured or calculated. That’s the key

to understanding exactly what the thing is,

what variables are in play, and what relation-

ships are important.

FeedRate = RPM×NumberOfFlutes × ChipLoad

Chip Load

Chip load is the amount of material removed by

each flute’s tooth as it makes one revolution

while being pushed along at a feed rate and

spindle speed. Chip load is measured in feed

per tooth, or inches per revolution, abbreviated

as IPR:

ChipLoad =

FeedRate

RPM × NumberOfFlutes

1. Under the hood, Shop-

Bots are configured in

inches per second. Either

way, feed is still length

traveled per time elapsed.

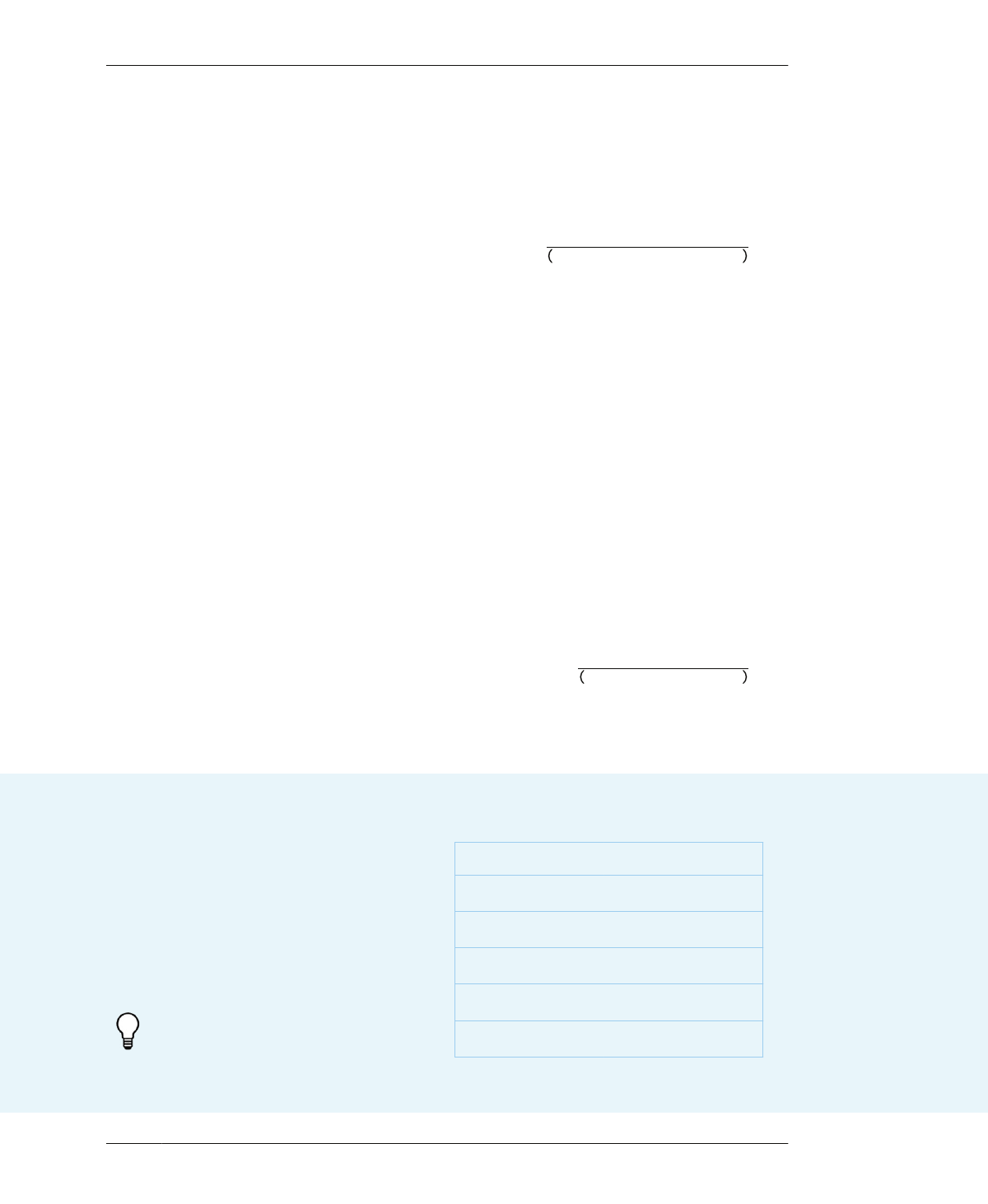

ROUGH CHIP LOADS BY MATERIAL

The chip load, feed, and speed formulas all take individ-

ual tool geometry into account by including the number

of flutes (cutting edges) into the equation.

While actual chip load is different for each specific tool

geometry, chip load generally increases gradually with

bit diameter. Some rough chip loads for sheet materials

are shown in the following table. 2

Onsrud provides chip load data specific to

their tooling. For more information, see http://

www.onsrud.com/xdoc/Feed-Speeds.

CHIPLOAD

Softwood

Hardwood

MDF

Plywood

Laminated Chipboard

1/4 inch

.002-.020

.005-.020

.005-.030

.005-.020

.008-.020

1/2 inch

.003-.030

.005-.030

.005-.020

.005-.030

.010-.030

2. Onsrud data compiled

by ShopBot and Centurion

Tools

06/MACHINING FOR DESIGNERS

145