SPINDLES AND SPEED

SPINDLES AND SPEED

Generically, a spindle is a rotating shaft that

transfers motor power to a cutter as it spins

around an axis. When applied to a material, the

tool attached to the spinning spindle bites into

the substance, creating subtractive waste

products, called chips, with each revolution.

The frequency of rotation, or speed, of a turn-

ing mechanical component around a fixed axis

is measured in revolutions per minute. Rota-

tional speed can be abreviated as: RPM, rev/

min, or r/min.

On a machine, the term “spindle” refers to the

entire motorized assembly that moves up and

down the z-axis, not just the shaft. Spindles

conventionally spin clockwise (although there

are a few that spin counter-clockwise), and

most tooling—and all the machining informa-

tion in this book—assumes a clockwise rota-

tion.

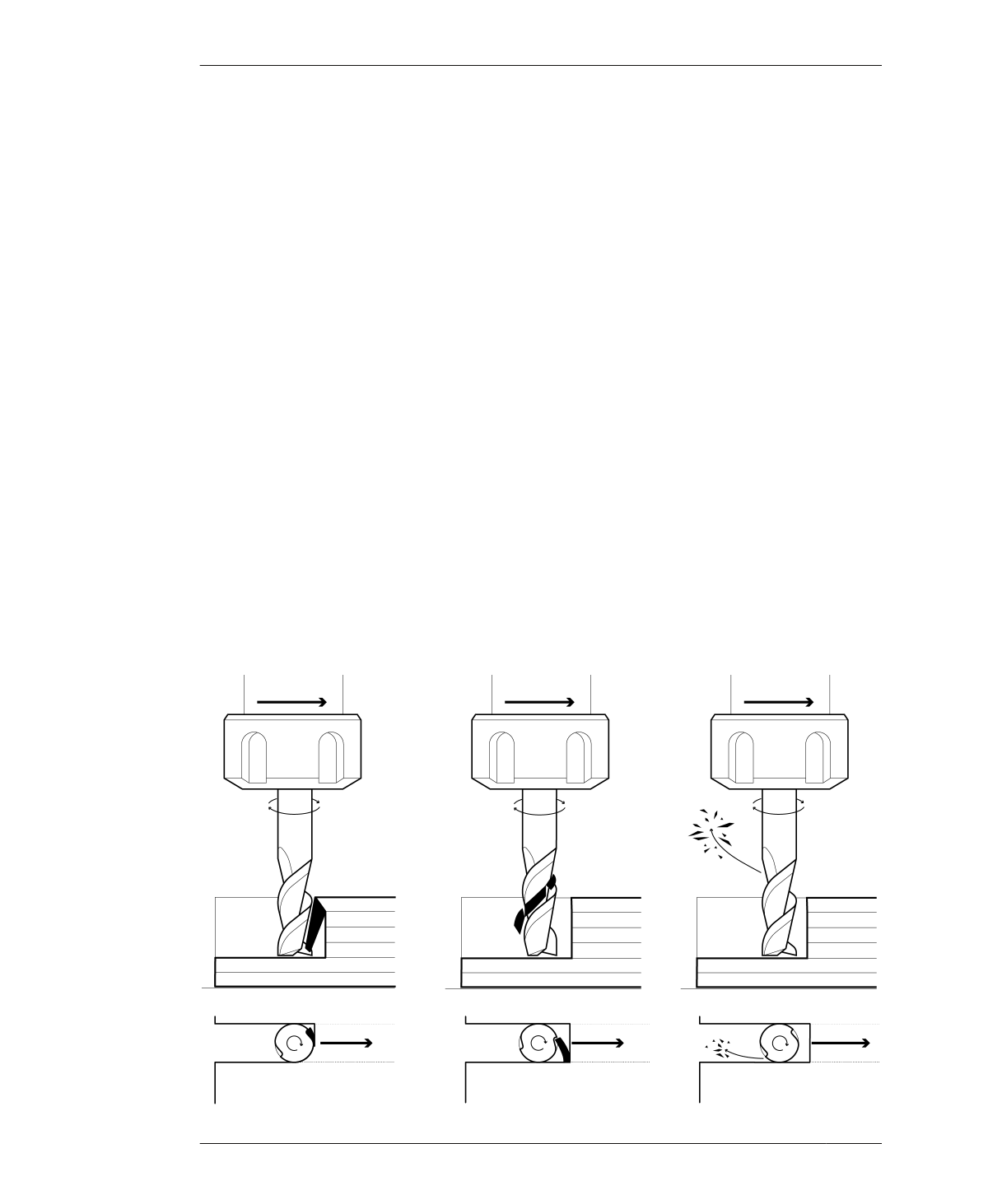

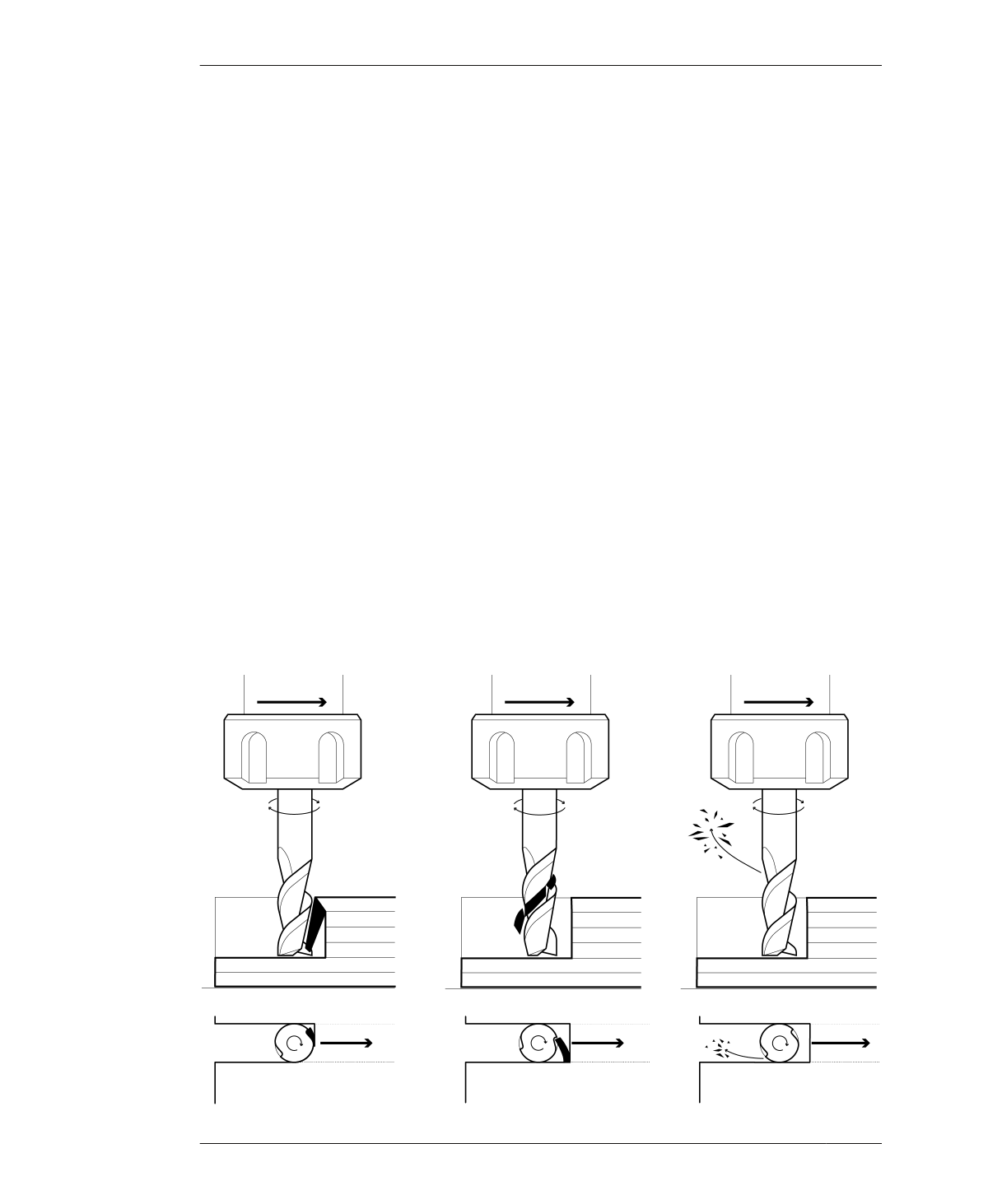

CHIP FORMATION

As the spindle turns a tool, the cutting edge sli-

ces into the material, removing a fragment

called a chip. The size of the chip is called chip

load.

Chips are not just the waste product of machin-

ing—they are key to heat dissipation. The act of

cutting a chip generates a small amount of fric-

tional heat. Chips absorb this heat, pulling it

away from the tool and the workpiece, as they

are ejected through the flutes. If this heat were

allowed to build up, it could quickly dull tools,

leave burn marks on wood, or even start a fire.

Creating chips that dissipate heat quickly while

balancing both cut quality and time spent is

fundamental to machining. The speed that a

machine turns a cutter has an impact on what

materials can be cut and what type of tool can

be used. Different machine types have different

ranges of spindle speed.

FIGURE 6-1

Chip formation

142

DESIGN FOR CNC