PROTOTYPING

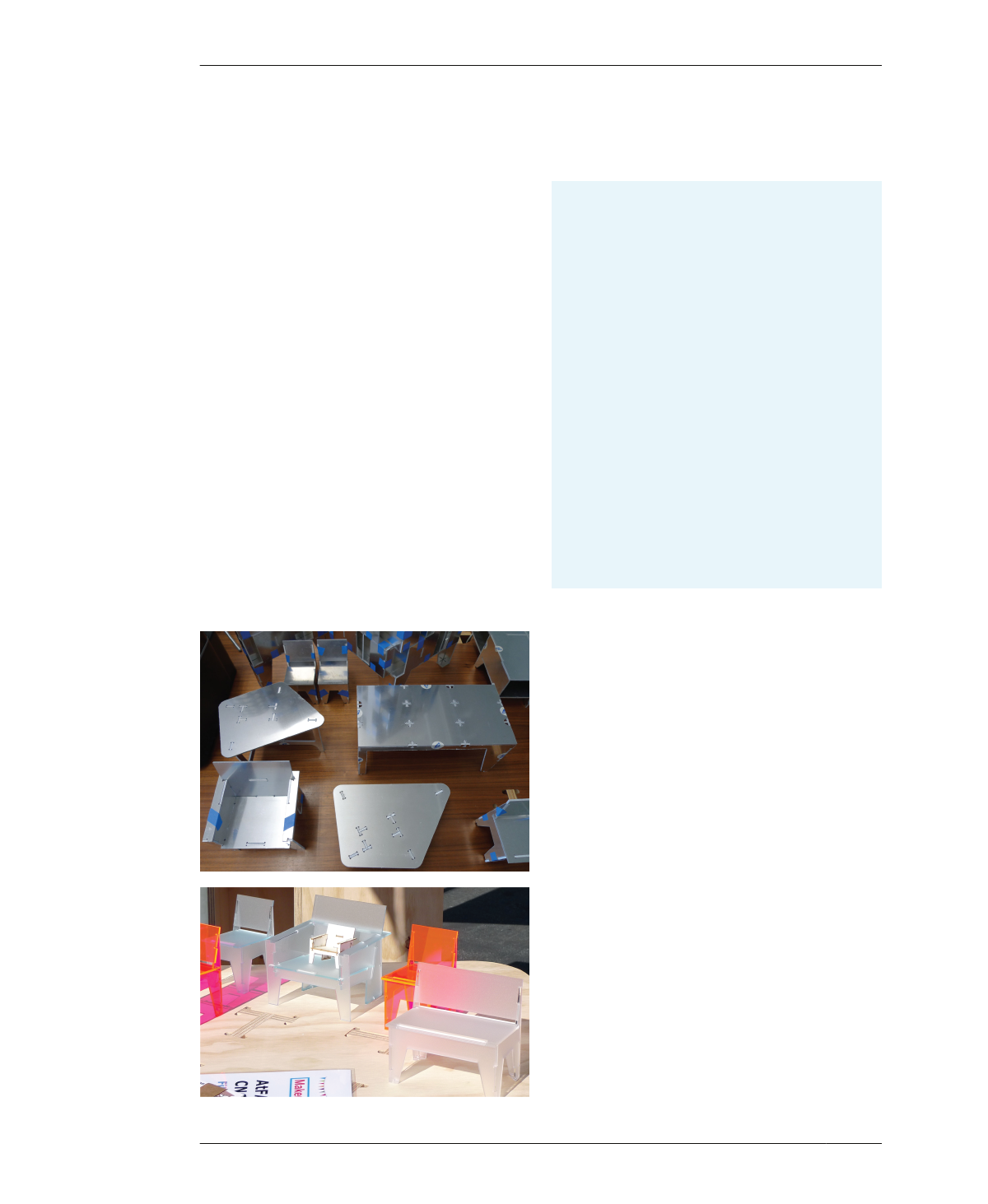

FIGURE 5-10

Scale furniture proto-

types made of 1⁄8″ alu-

minum cut by a CNC

waterjet

space, you have a quick and inexpensive way to

make scale prototypes of digital designs.

Although they are small, scale prototypes can

assist you in analyzing structural integrity, test-

ing accurate fit between parts, and evaluating

complex patterns or embellishments. They’re

also helpful if you’re making modifications to

the projects throughout this book, as they help

confirm that you haven’t misplaced a sniglet or

misaligned a joint. Scale prototypes allow you

to see the overall composition of details in

physical space. Understanding the whole

object enables you to intelligently analyze a

design in ways that you may have not imagined,

when looking at the CAD screen.

To prepare a scale prototype file, you simply fol-

low the same steps as you would in adjusting a

CAD file (explained in “Scale Your CAD File” on

page 133). The only difference is that thin pro-

totyping materials like acrylic or cardboard

have a TMAX, which is much smaller than

nominal plywood thickness. Scaling toolpaths

to match this thickness requires a much

smaller S percentage.

SURPLUS MATERIAL

Always purchase extra material for testing and for

recutting parts. Surplus plywood is also useful for

partial prototypes and in the event that a part is

damaged during the cutting, finishing, or assembly

process. With extra material on hand, you can easily

cut a replacement part for one that was damaged by

human or machine.

As you embark on your first projects, we recom-

mend that you purchase a second sheet of plywood,

or cut a small project and reserve the other half

sheet for testing.

In the project chapters, we recommend that you

have at least 1'x4’ of additional material on hand for

every project in this book—but it’s a best practice to

have an extra half or full sheet around.

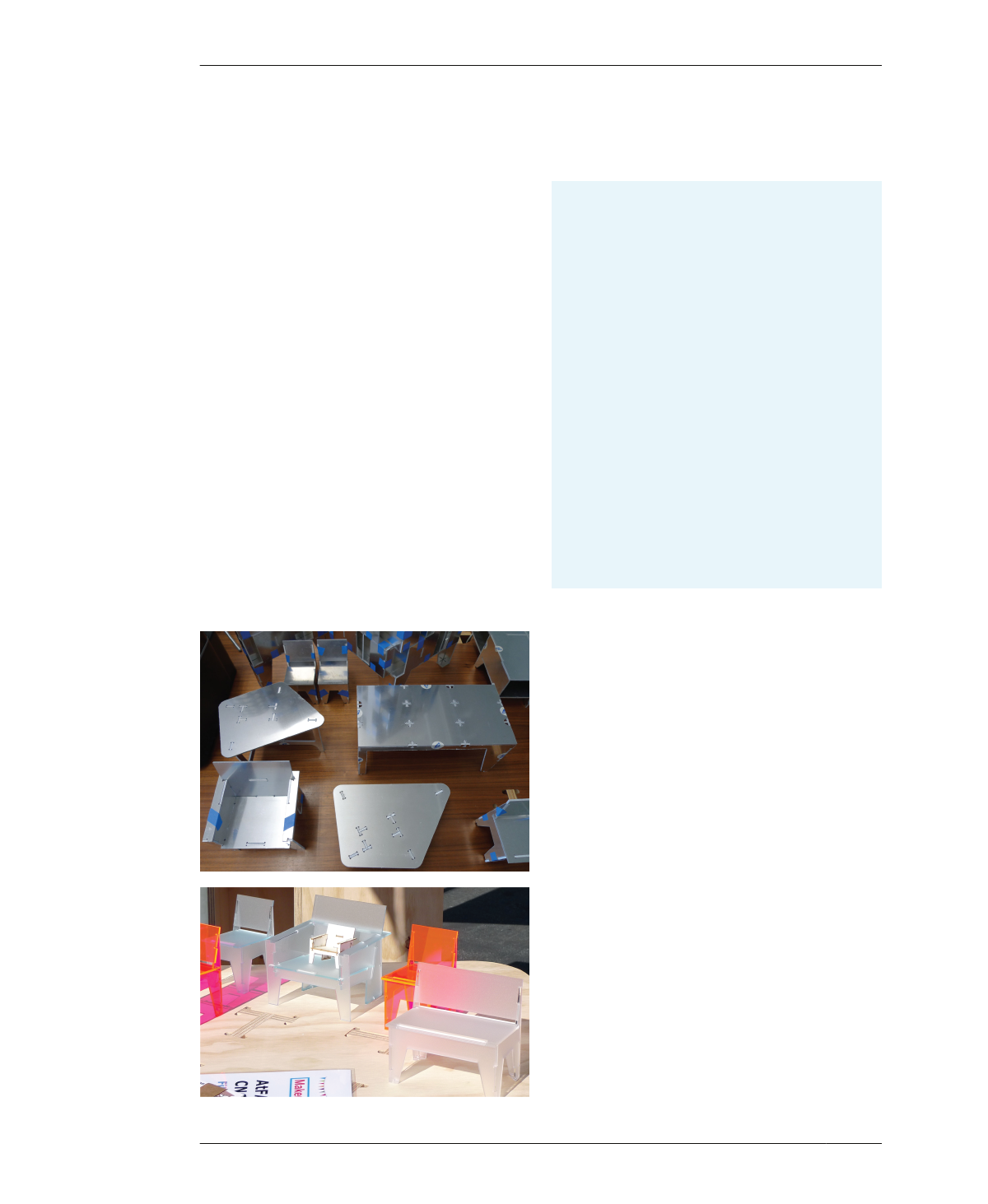

FIGURE 5-11

Chair prototypes in dif-

ferent scales made of

laser-cut plexiglass and

chipboard

138

DESIGN FOR CNC