PROTOTYPING

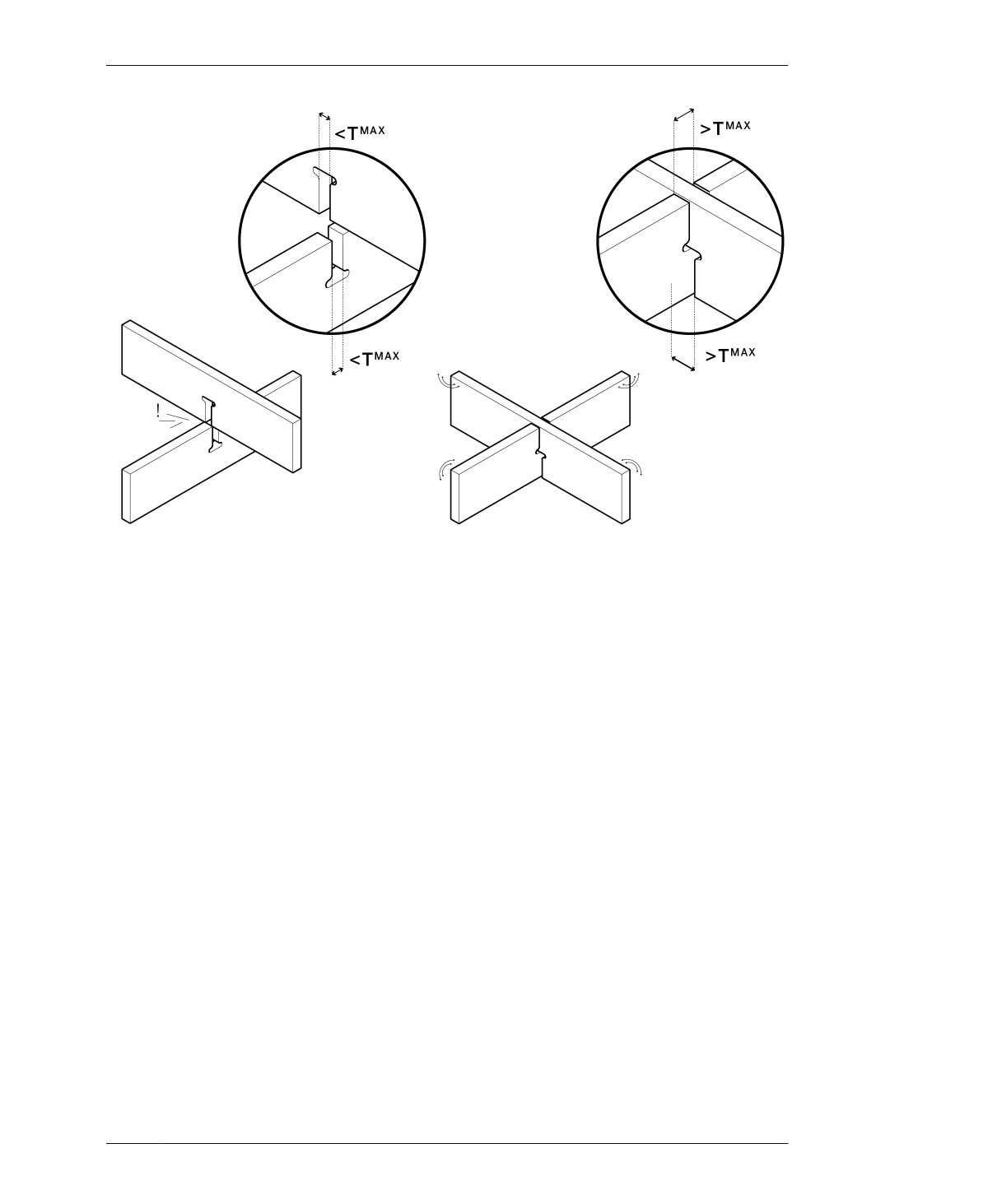

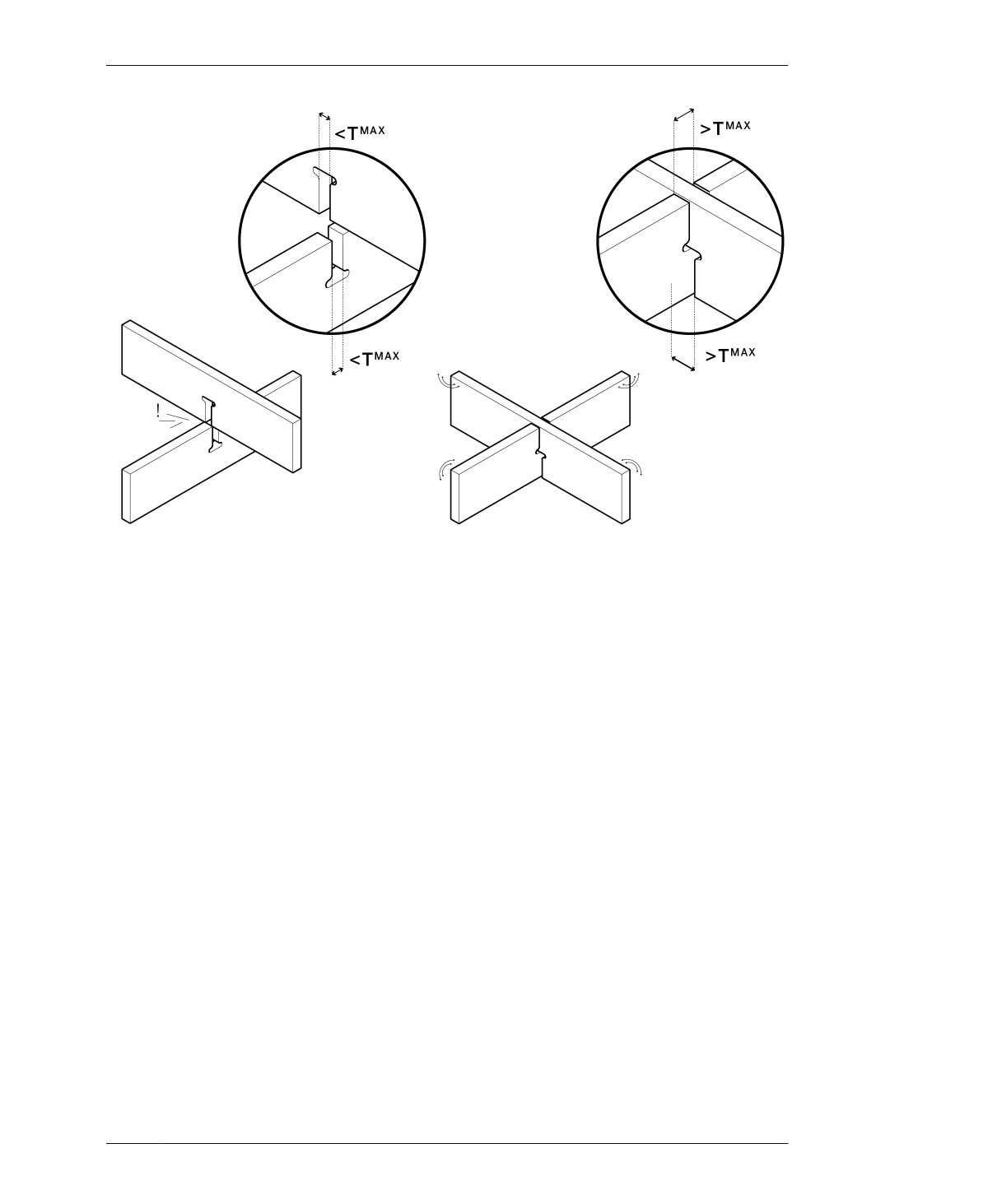

FIGURE 5-9

Joinery fit: too tight

versus too loose

Preliminary fabrication tests prevent the disap-

pointment and waste that comes from cutting

an entire piece of furniture with incorrect set-

tings. Each project’s test piece was designed to

use as little material as possible, but still be

large and detailed enough to allow a thorough

analysis of all the joint conditions within the fur-

niture piece.

To ensure that your test piece properly simu-

lates the critical joinery of your project, it’s

essential to fabricate it exactly as you would

the actual furniture piece. First, you apply iden-

tical scaling adjustments (S) to the 2D test

piece vectors in CAD (as explained in “Scale

Your CAD File” on page 133). From there, you’ll

assign identical toolpath settings in CAM soft-

ware (which will be explained in “Partial Proto-

typing: Using a Test Piece” on page 212), and

proceed to cut the test piece from the exact

material that you’ll be using for the actual

piece.

Most of the time, these careful steps lead to a

test piece with perfectly fitting joinery, enabling

you to confidently proceed with cutting your

project. When joints aren’t perfect, however,

the test piece is small enough to quickly make

digital adjustments, cut another test piece, and

compare the new fit to the previous one

(“Troubleshooting” on page 202 goes into

greater detail with these steps). The beauty of

prototypes is that they enable the iteration

that’s necessary for flush joinery, the hallmark

of digital craftsmanship.

SCALE PROTOTYPES

Scale prototypes are small-scale versions of a

design, cut with a desktop CNC or laser cutter

out of inexpensive materials like cardboard,

plexiglass, or aircraft plywood. They differ from

partial prototypes in that they can be used ear-

lier in the design process. If you have access to

a laser cutter at your workshop or fabrication

05/PRECISION-FIT PLYWOOD JOINERY

137