PROTOTYPING

PROTOTYPING

Prototypes are used to evaluate a design at

varying stages during the design and fabrica-

tion process.

From a practical standpoint, prototyping allows

you to identify errors and troubleshoot defects

before committing to making a full-scale, final

piece. From a design standpoint, prototypes

enable you to take risks with innovative ideas

and to gather immediate feedback. Working

digitally enables rapid prototyping, where you

can iteratively cycle through a process of

designing, prototyping, and making improve-

ments, over and over.

Prototypes can take many forms, but for CNC

furniture there are two kinds that are especially

useful. Partial prototypes made at full scale are

essential to digital craftsmanship, by helping

you to dial in machine settings and to evaluate

finishing techniques. Scale prototypes, made

by fabricating your digital file at a smaller scale,

are great for evaluating a new or modified

design.

PARTIAL PROTOTYPES

Partial prototypes are small samplers of a larger

design that you make using your actual project

material. A partial prototype is great for trying

out especially complex and tricky portions

within the design, before committing to the fab-

rication of an entire design. Partial prototypes

are also quite useful for evaluating joinery fit

and ensuring that you scaled the CAD file to

perfectly match TMAX.

TEST PIECES

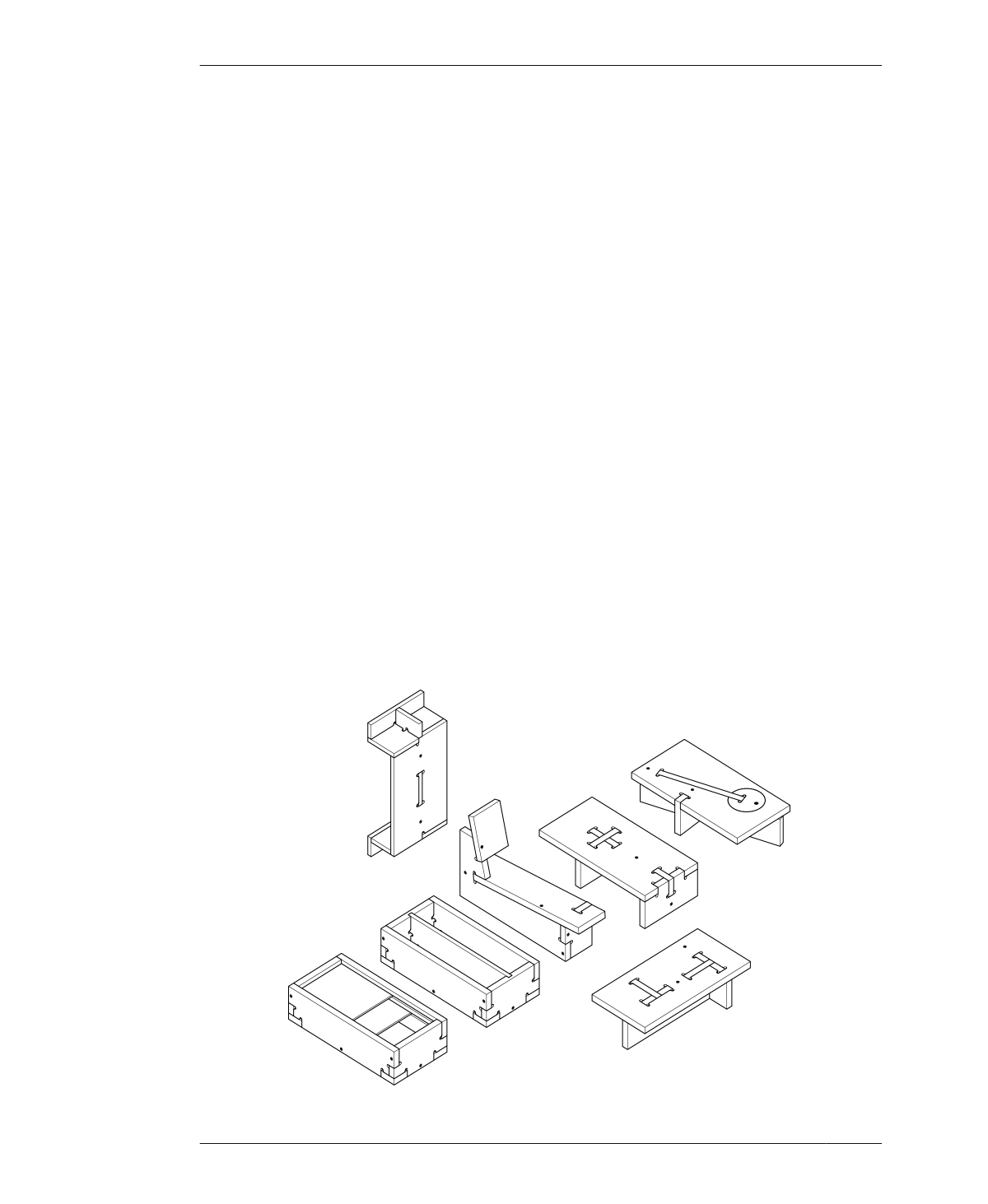

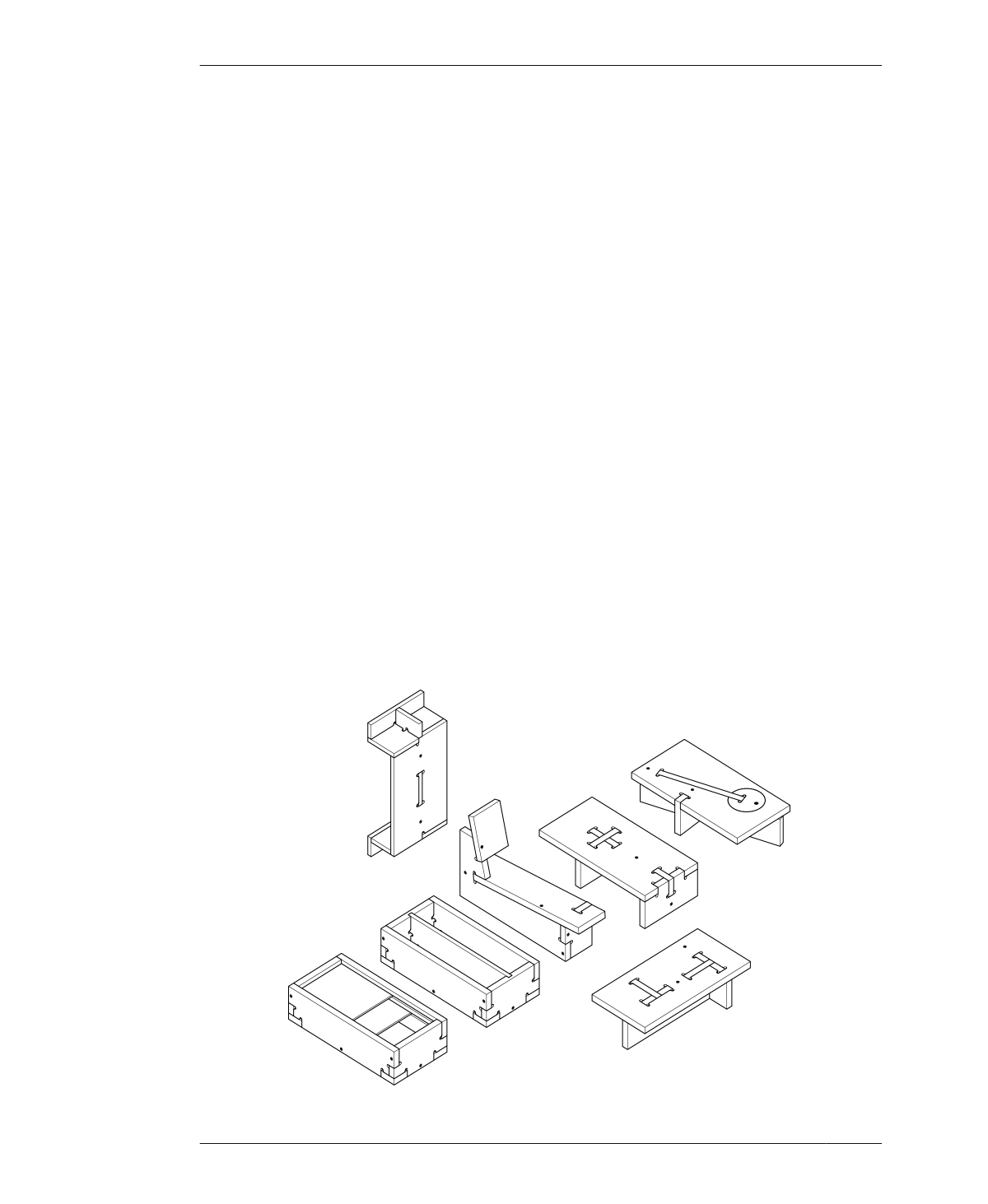

Each project in this book is accompanied by a

partial prototype called a test piece, shown in

Figure 5-8 and in the image that opens this

chapter. They were designed to simulate the

most complex joint combinations within each

project. After measuring materials and scaling

a CAD file, fabricating this test piece is the next

step for ensuring tight-fitting joinery.

FIGURE 5-8

Partial prototype test

pieces for each project

136

DESIGN FOR CNC