HOW TO DIGITALLY DIAL IN JOINERY FIT

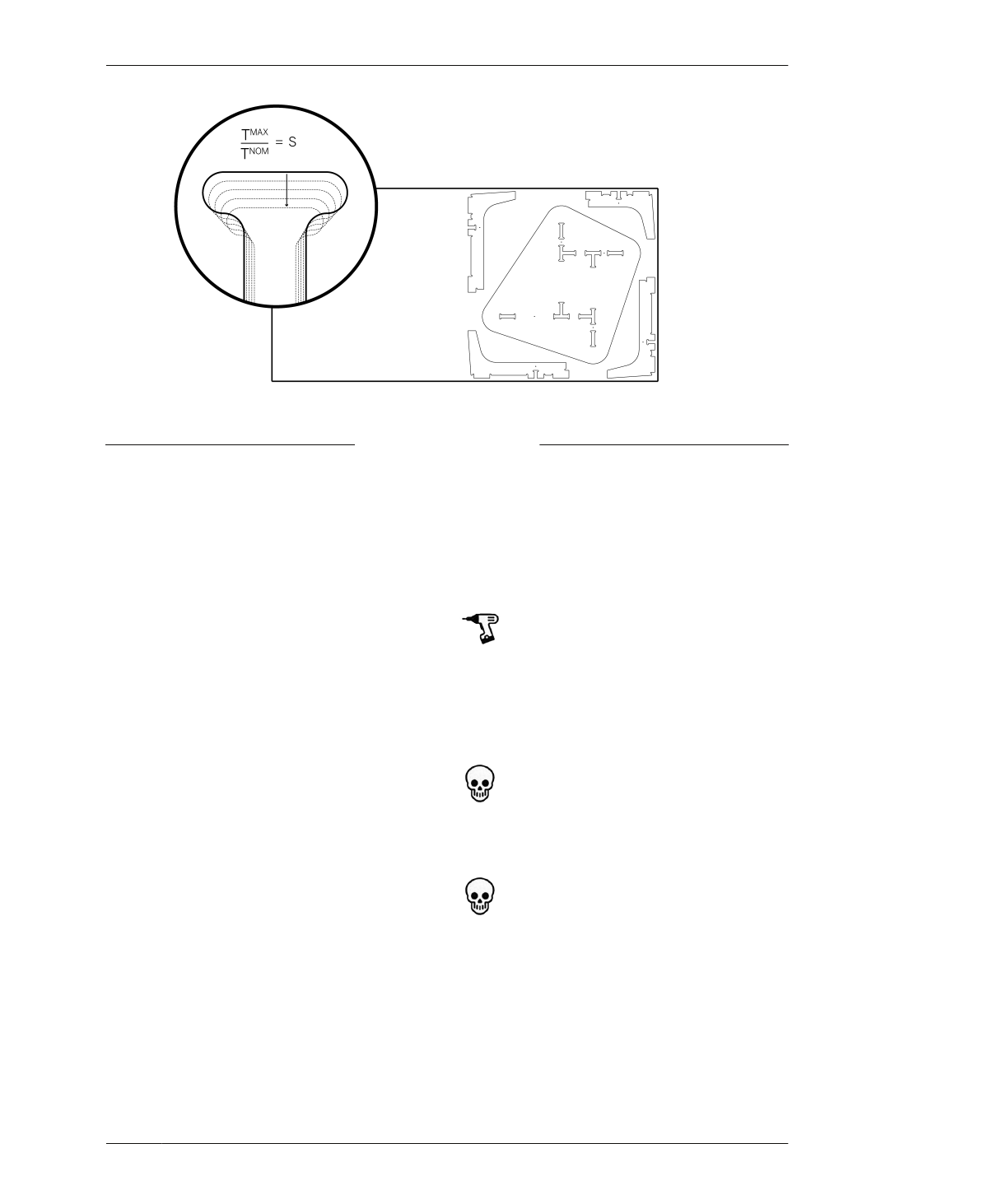

FIGURE 5-4

Scale cut file by S,

matching joinery to

TMAX

SCALE YOUR CAD FILE

The natural fluctuation of sheet material thick-

nesses makes standardization—and standard

cut files—impossible. Because your actual

material thickness (or TMAX) will never pre-

cisely match the designs file’s nominal thick-

ness (or TNOM), you’ll need to scale your CAD

file to match your material thickness or your

joints won’t fit together. Cutting parts from an

unadjusted CAD file will produce parts that

won’t fit. Joinery will either be too loose, leaving

parts to rattle around, or too tight, with tabs

too fat to fit through slots.

Luckily, scaling your CAD file is a simple pro-

cess.

2A: TMAX / TNOM = S. Divide your measured

material thickness (or TMAX ) by the nominal

material thickness of TNOM to get S—a scaling

percentage.

2B: In the SketchUp file, turn on only the

toolpathing layers.

2C: Select all 2D toolpaths on the toolpathing

layers and then scale them by S, the scaling

percentage.

2D: Save and rename the file. Add the amount

scaled to the filename (e.g., AtFAB_CiBii-.

9867.skp). This differentiates it from the origi-

nal, unscaled version of the file, and indicates

the file’s scale. You’ll forget!

Small-scale adjustments usually won’t have

an impact on fastener holes. If you want to

maintain a specific hole diameter for particu-

lar fasteners or pegs, scale holes with the rest

of your vectors and then change the dimen-

sion of the 2D hole component.

Check that S does not reduce the cut file

scale by too much. Sniglet diameter should

always be equal or greater to your end-mill

dimension.

Since different designers may use different

standards, it’s good to make a habit of meas-

uring slots and material thickness in any CAD

file that you download. AtFAB files on Open-

Desk, and other files floating around the inter-

webs, may use an 18mm TNOM.

05/PRECISION-FIT PLYWOOD JOINERY

133