SNIGLETS AND FASTENERS

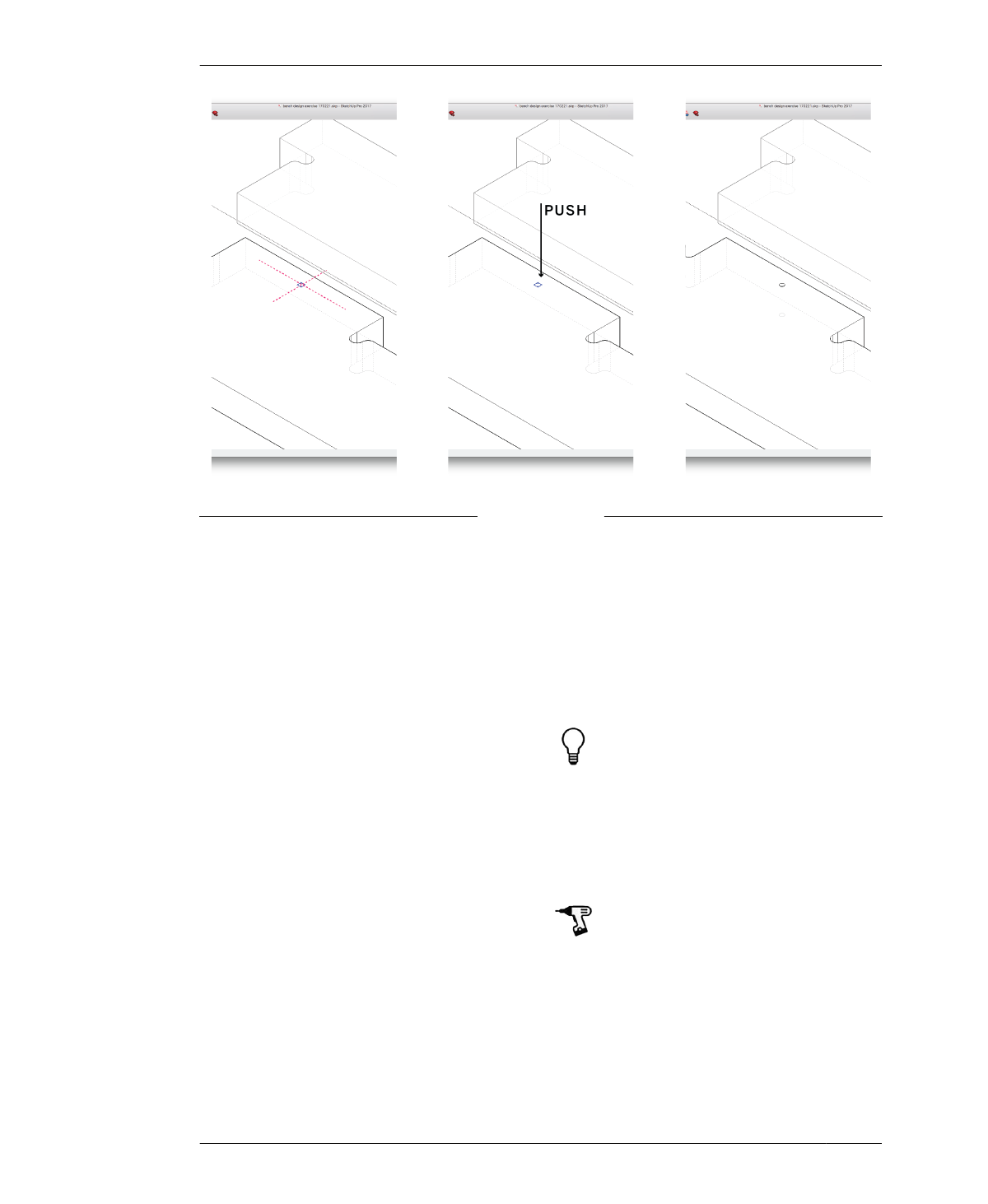

FIGURE 4-33

Locate and make holes

MODEL HOLES

To ensure a fastener securely attaches two

parts together, center holes so that they are in

the middle of a tab and in the middle of the

material thickness, as shown in the far left in

Figure 4-33. Working in the 2D parts layout,

draw temporary reference lines to assist you in

accurately placing all fastener holes.

25A: Working with one 2D part at a time, draw

reference lines to help you center holes in the

middle of each tab.

25B: Select a hole component and center the

hole at the intersection of the reference lines.

Be sure to work outside of the part component,

as you place the holes component. See the

center illustration in Figure 4-33.

25C: Select the collection of hole components

for a single part and go to Edit→Cut.

25D: Fully select and edit the part component,

place holes, and explode them.

25E: Using the Push/Pull tool, push the hole

shape into and all the way through the part, as

seen in the far right of Figure 4-33.

25F: Exit the component and repeat until all

the parts have holes.

25G: Delete the guidelines.

Sometimes it isn’t possible to fit a fastener

into tight spots, like in between tabs in the

hanger and foot assemblies. Since the fasten-

ers only need to assist the joinery in holding

parts together, you can omit any fastener hole

that seems to crowd the joinery.

A 3/16” diameter hole requires an 1/8” end-

mill to cut it. By making the hole a compo-

nent, you’ll be able to adjust its diameter to

match any end mill or fastener that you want

to introduce.

122

DESIGN FOR CNC