SNIGLETS AND FASTENERS

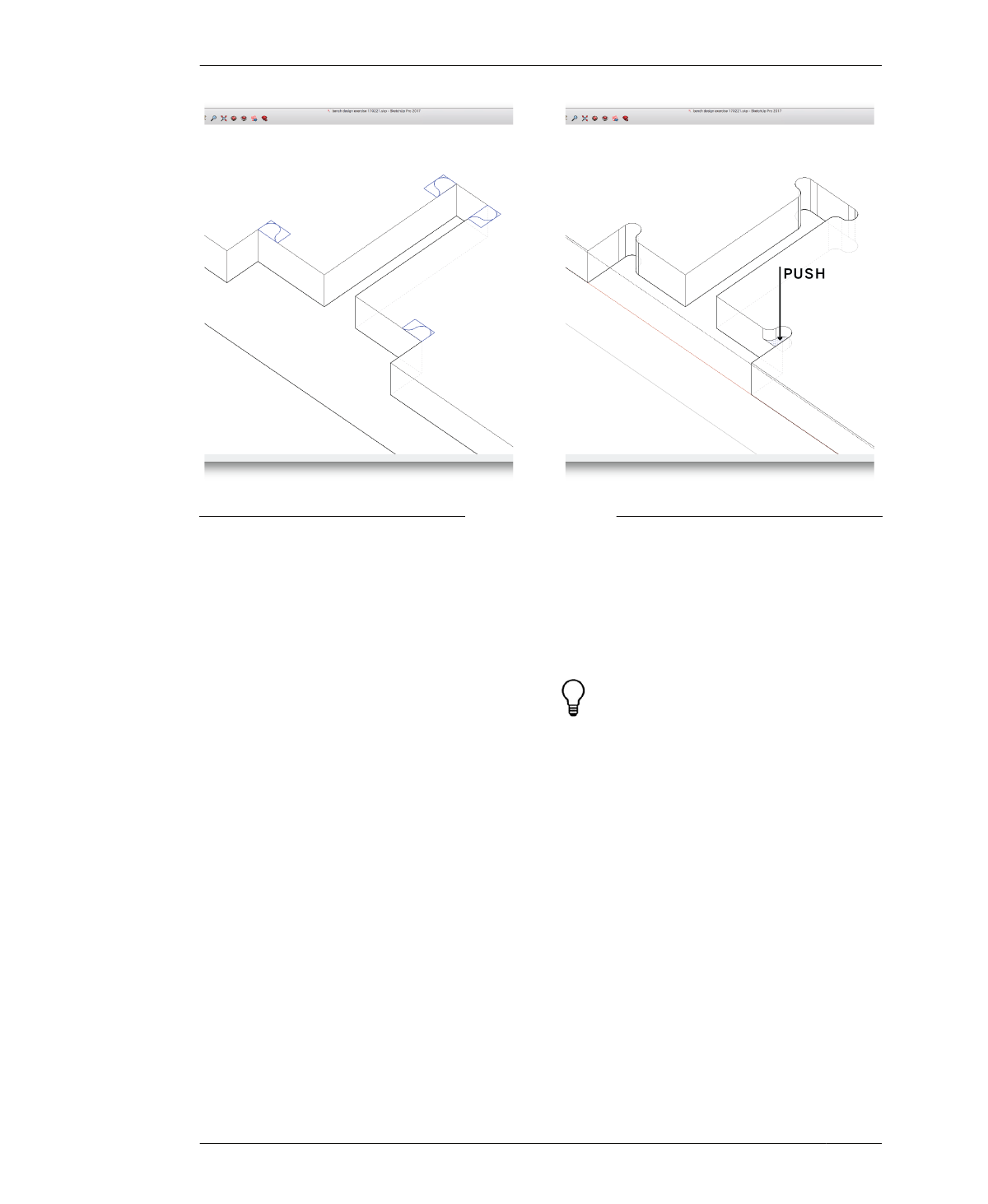

FIGURE 4-30

Locate sniglet profiles

and then form into 3D

MODEL SNIGLETS

Sniglets go into every interior corner, to elimi-

nate corner material and to accommodate

flush-fitting joinery. While some CAM programs

(like VCarve Pro) have utilities you can use to

add dogbone or T-bone fillets to your design,

this extra step allows you a bit more control.

You can pay more attention to the actual corner

detail profile, while also thoroughly considering

its exact direction and placement in the overall

design.

24A: Working on a 2D flattened part, place a

sniglet at every inside corner. Be sure to work

outside the component itself as you place and

arrange sniglets.

24B: Select the collection of sniglet compo-

nents and go to Edit→Cut.

24C: Select and Edit the part component.

Edit→Paste the sniglet collection and explode

the individual sniglet components.

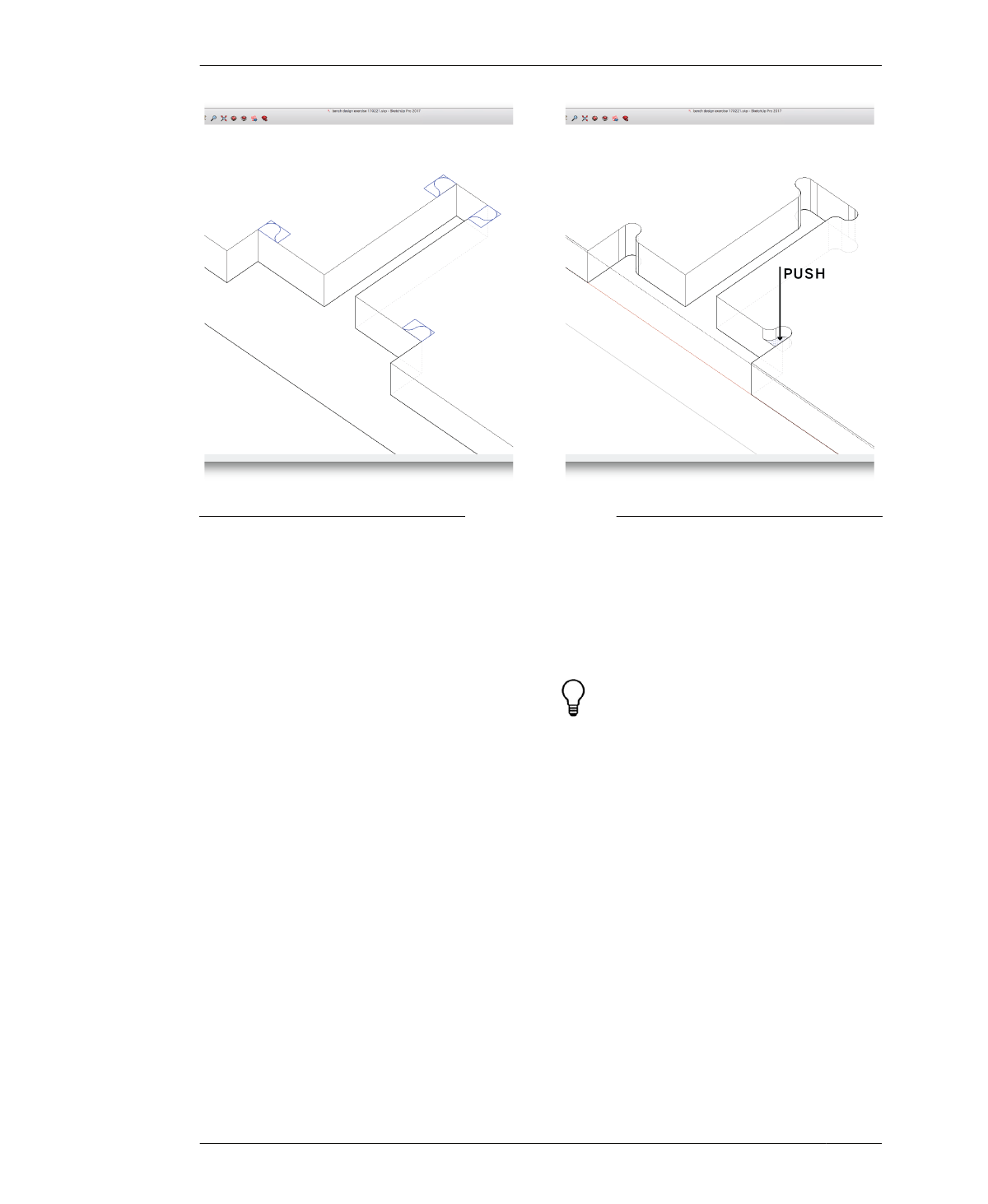

24D: Using the Push/Pull tool, push the snig-

let shape into and through the part.

24E: Exit the part component and repeat until

all parts have sniglets on every inside corner.

It’s usually more convenient to work on the 2D

parts as you introduce sniglets and holes,

especially in those cases where access to the

part is limited. When you want to work on

parts configured in 3D, it’s helpful to use

transparency view options as much as possi-

ble, so you can clearly understand parts. It

can also help to isolate or temporarily move

components in 3D to work on them.

120

DESIGN FOR CNC