MAKE JOINERY

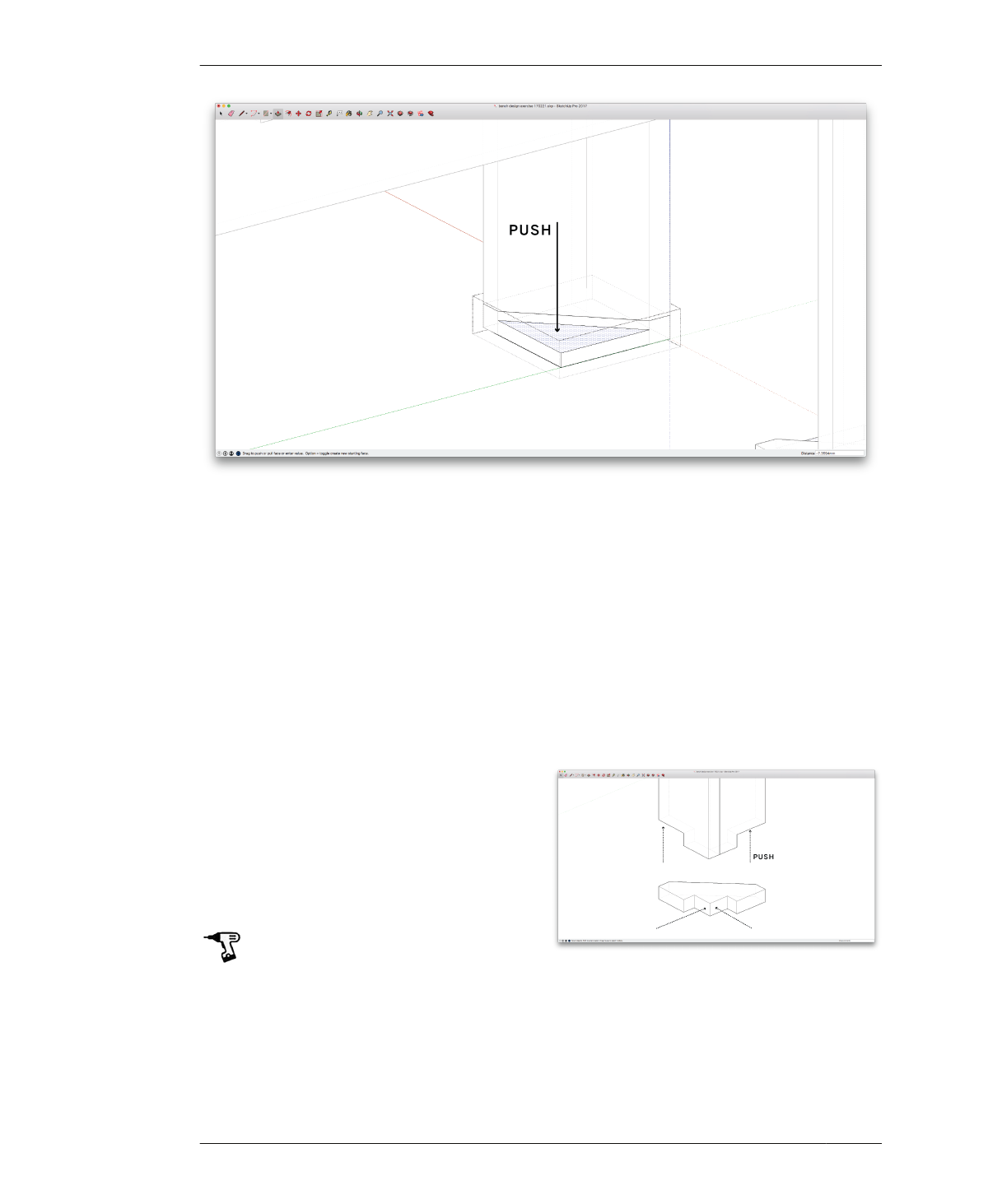

FIGURE 4-26

Push to remove triangle

shape from square foot

part by part to form the joinery that connects

the foot to the base of the legs. As you work

your way around parts, rotating the 3D view will

help you to better see and select surfaces.

20A: Rotate the view, so you can see the

inside of the leg assembly.

20B: Draw a diagonal construction line at the

intersection between the foot and each leg.

Select this line and go to Edit→Cut.

20C: Remove the inside triangular corner.

Fully select the foot component and Edit→Paste

this construction line into the component.

Using the Push/Pull tool, push down to remove

a triangular shape from the foot, as shown in

Figure 4-26.

20D: Exit the foot component.

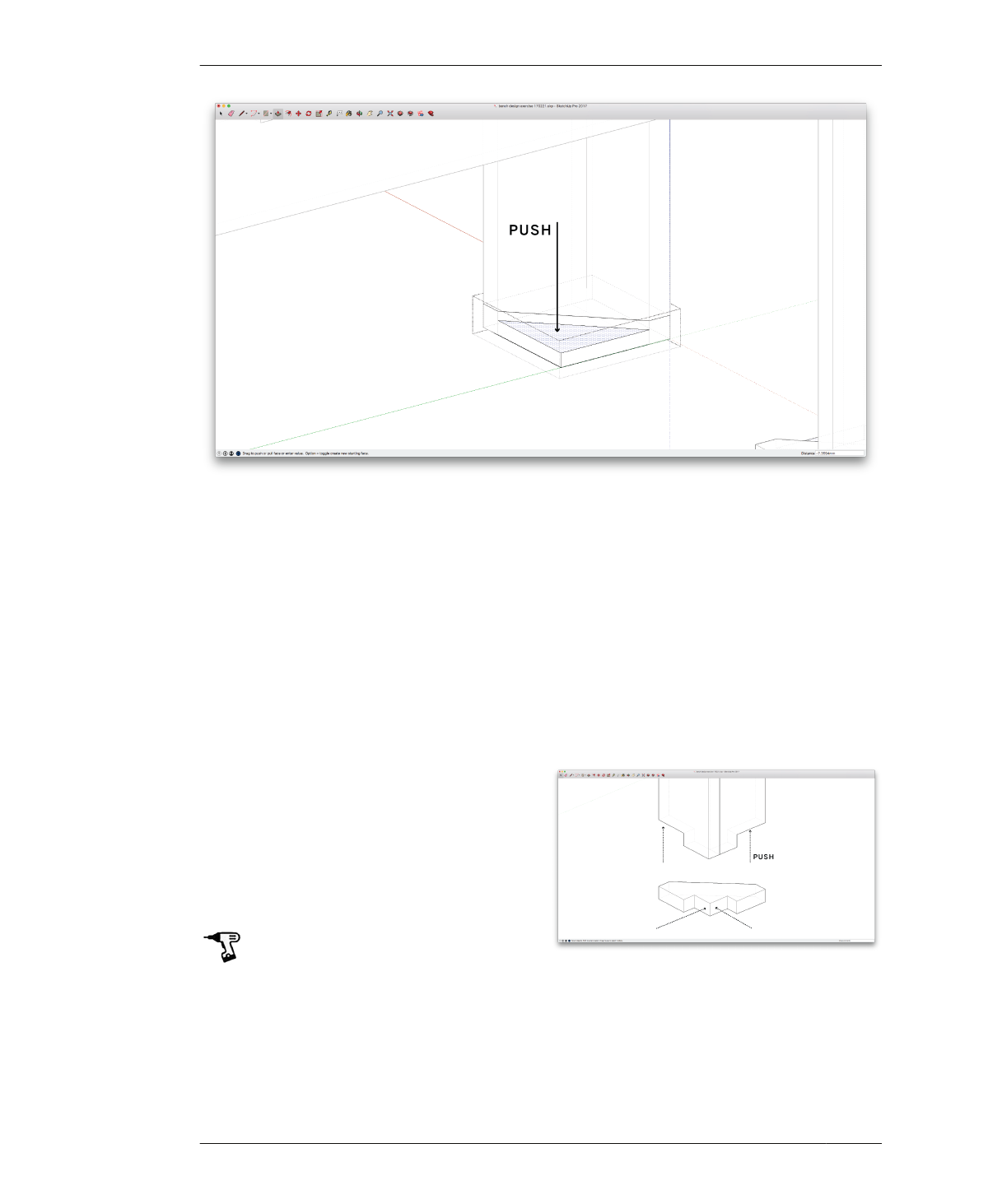

20F: Locate the tabs on feet and legs. Draw a

vertical construction line on the midpoint of

each outside face of the foot.

20G: Form the joinery between the foot and

legs, as shown in Figure 4-27. Starting with the

foot, use the Push/Pull tool to push slots into

the foot.

20H: Make tabs at the base of the legs, start-

ing with the side leg and then front leg. Make

matching slots on opposite legs of each part.

Now that you’ve given the foot a direction,

check your 3D model. You may need to rotate

your other foot component copies so that

they properly align with each leg.

FIGURE 4-27 Shape end-to-end-to-end joint

20E: Rotate the view, so the outside of the leg

and foot is visible.

116

DESIGN FOR CNC