MAKE JOINERY

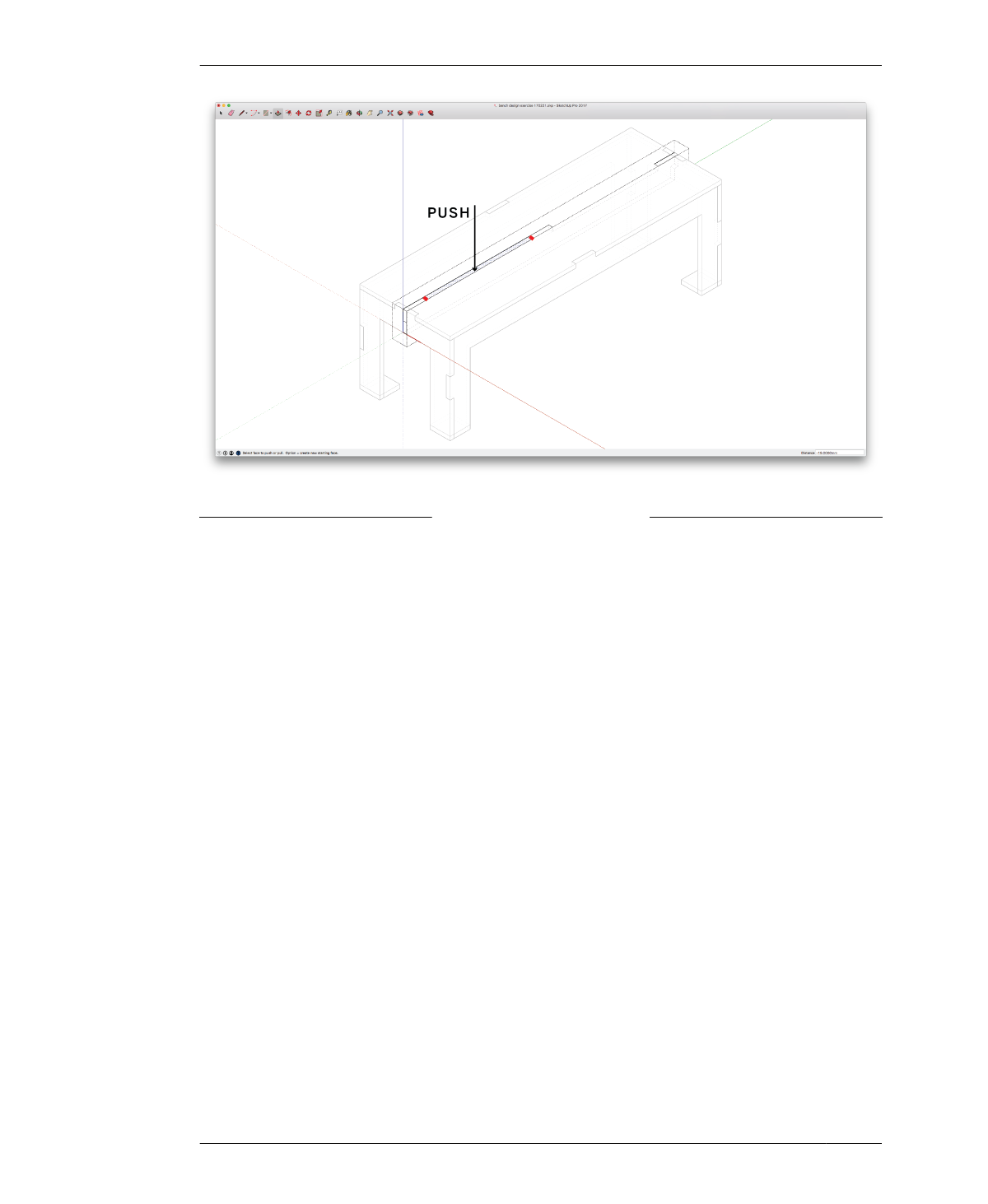

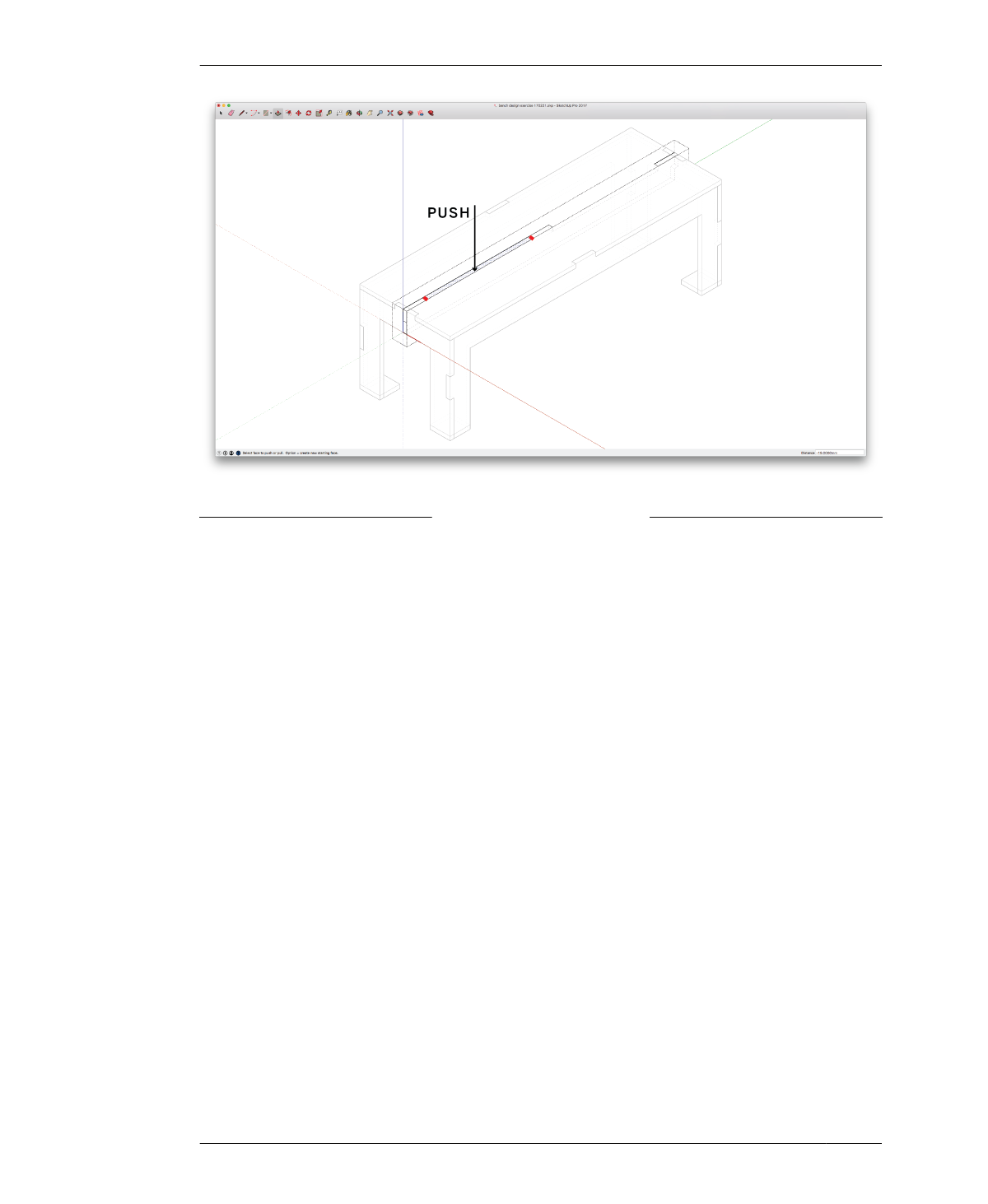

FIGURE 4-23

Push into top of beam,

to form center and end

tab

MAKE HANGER ASSEMBLY

Forming a hanger assembly requires the same

techniques used previously, this time to modify

three parts, the beam, side, and seat. While it

seems like a complex intersection of parts, they

are easily shaped if you go part by part and

draw construction lines to form the Push/Pull

surfaces. Use the guidelines, as well as previ-

ously drawn slots, to help you locate construc-

tion lines accurately.

19A: Draw a horizontal construction line 4′

across the top end of the beam. Draw a second

construction line where the end of the seat slot

intersects the beam. Select all construction

lines and select Edit→Cut.

19B: Select the beam component. Paste the

construction lines into the component. Using

the Push/Pull tool, push the surface between

both lines ¾″ down, as shown in Figure 4-23.

19C: Repeat on the other end of the beam.

This leaves a 4″ × ¾″ × ¾″ tab at the middle

that fits the center slot of the seat.

19D: Draw a horizontal construction line at

the midpoint on the end of the beam. Cut/

Paste it into the component. Using the Push/

Pull tool, push the surface below the construc-

tion line ¾″ into the beam. This leaves a tab at

the top half of the beam. See far left illustration

in Figure 4-24. Repeat this on the other side of

the beam.

19E: Exit the beam component.

19F: Create a slot for the newly formed beam

tab. Use the beam tab to locate a construction

line. See far right illustration in Figure 4-24.

19G: Select the side component. Paste the

construction line into the component and push

the corresponding slot through the side.

19H: Exit the side component.

19I: Create a slot in the seat for the top beam

tab. Use the beam tab to locate a construction

line in the seat. Select the construction line and

go to Edit→Cut.

114

DESIGN FOR CNC