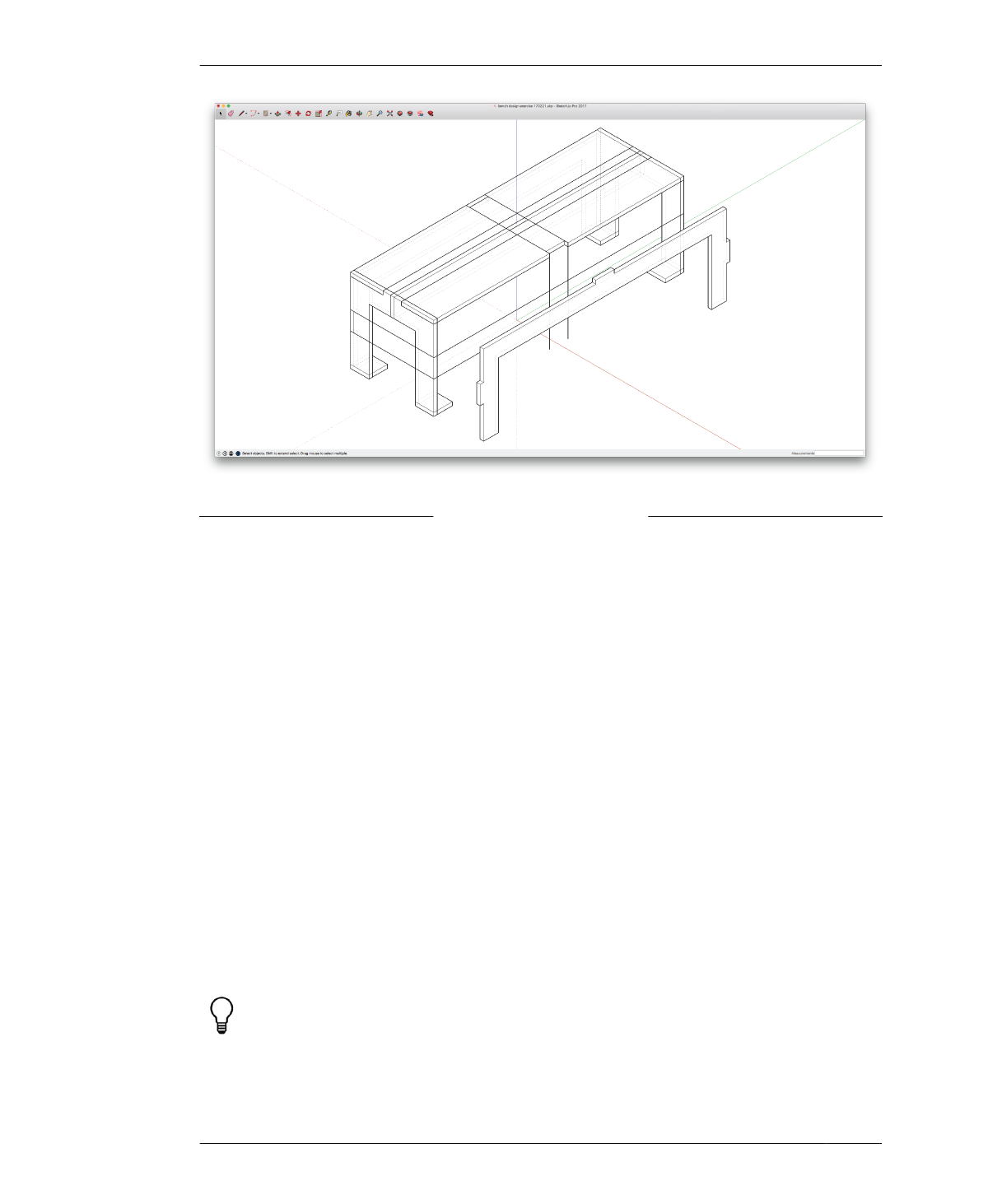

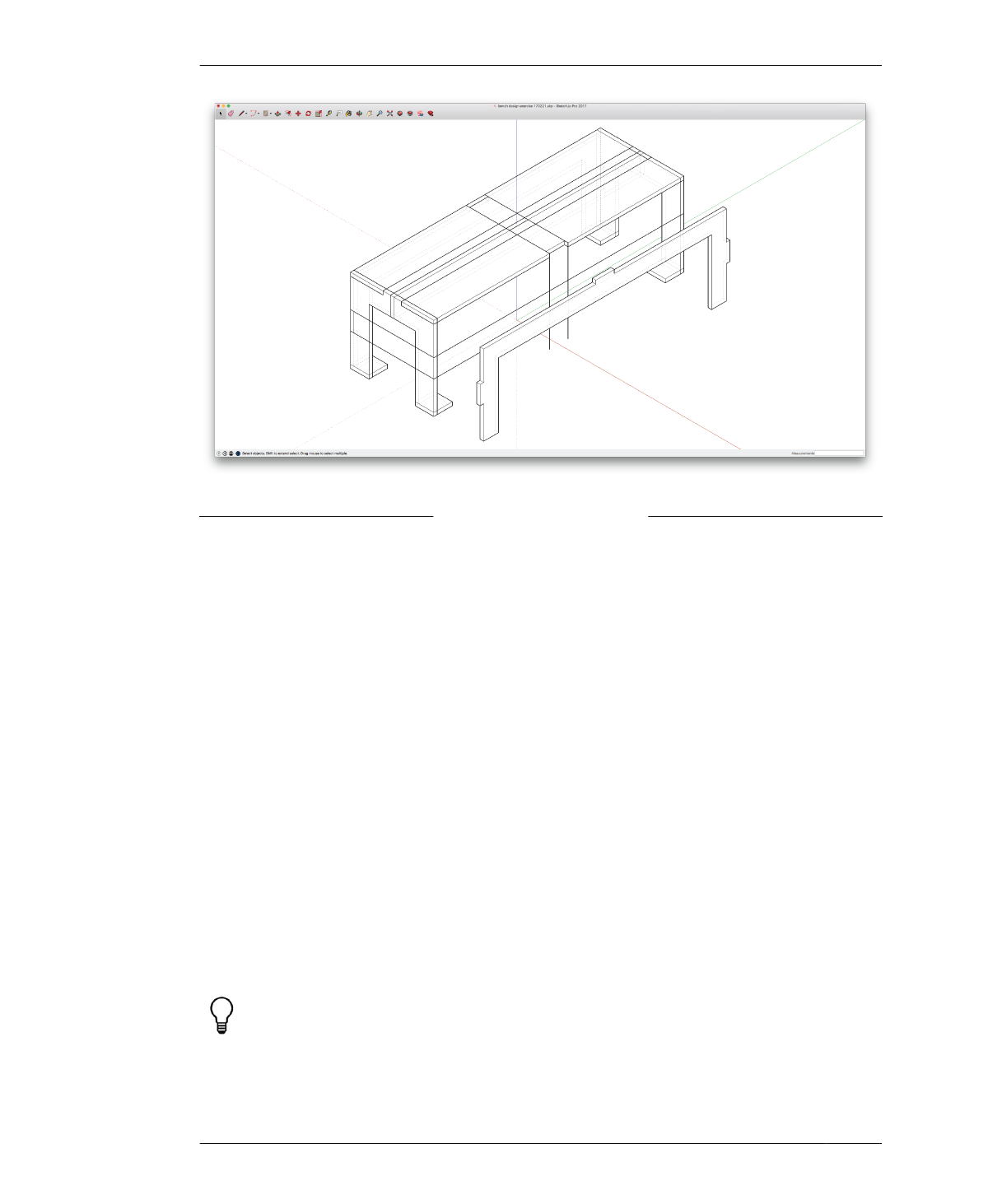

MAKE JOINERY

FIGURE 4-21

Front with three new

tabs

MAKE JOINERY ON FRONT

In this section, you’ll form slots and tabs to cre-

ate the end-to-end joints that comprise the cor-

ner assembly, connecting the front, back, and

sides. In these steps, you will apply the same

techniques of drawing construction lines to

help accurately define surfaces that you will

then push/pull into tabs and slots.

17A: Draw construction lines on the top edge

and two side edges of the front component,

using the guidelines as well as the slot you just

modeled on the seat front as a reference.

Select all construction lines and select

Edit→Cut.

17B: Fully select the front component three

mouse clicks are required to select and edit the

component. Edit→Paste the construction lines

into place.

17C: Using the Push/Pull tool, push either

end of the top edge down so that these edges

align with the bottom face of the seat. This

leaves a 4″ × ¾″ × ¾″ tab at the middle that fits

the front seat slot.

17D: Form a tab on the side of leg by using the

Push/Pull tool. Push the surfaces above and

below each side tab, leaving a 4″ × ¾″ × ¾″ tab

centered on the edge of the leg. Repeat on the

other end of the part.

17E: Exit the front component. The front part

should have three tabs, as illustrated in

Figure 4-21. Notice that the back part will auto-

matically update.

Use previously modeled slots and tabs as ref-

erences to assist you in drawing construction

lines and for pushing/pulling corresponding

slots and tabs into alignment.

112

DESIGN FOR CNC