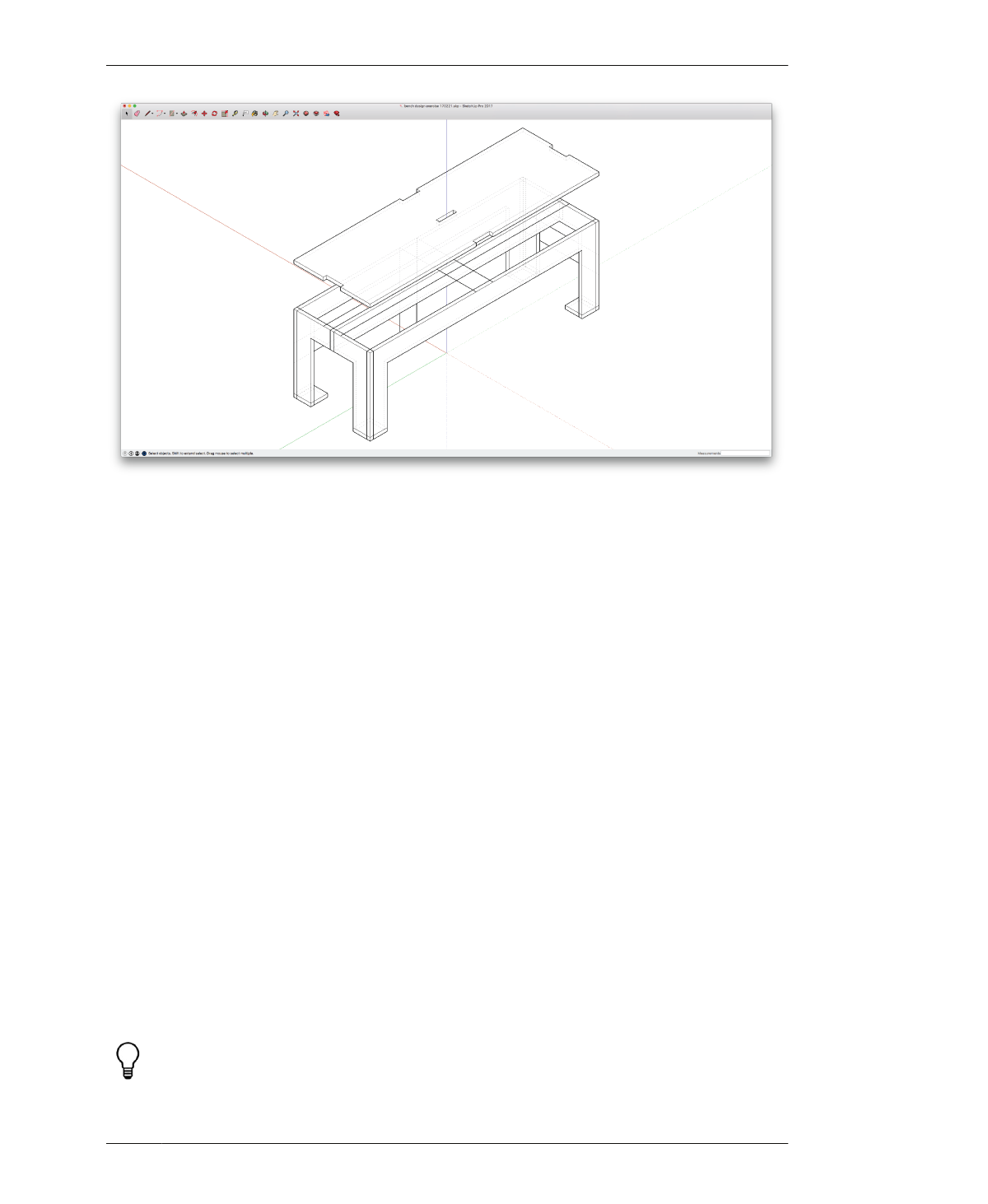

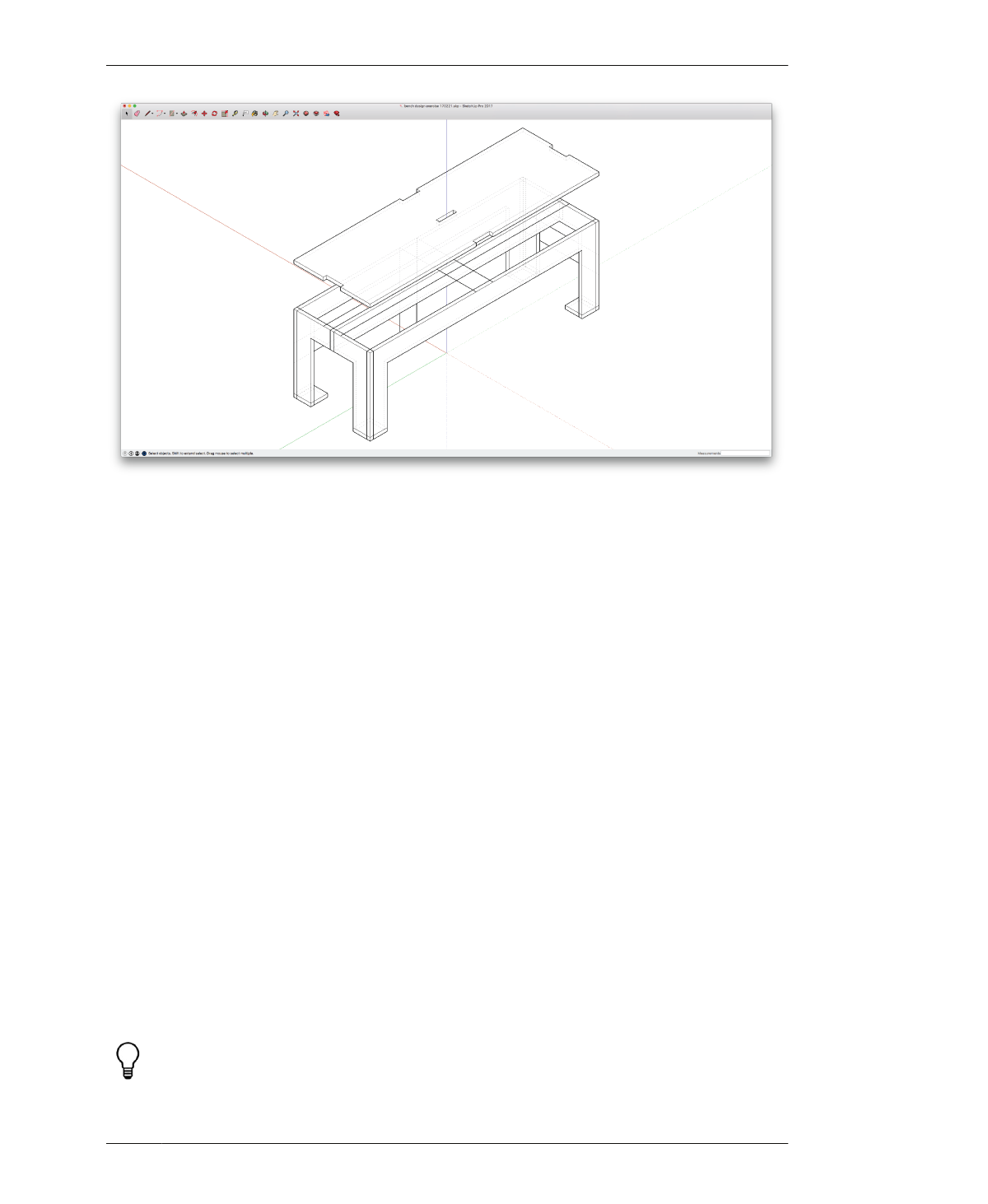

MAKE JOINERY

FIGURE 4-20

Seat with slots in sides

and top

16C: Form a 4″ × ¾″ slot at the end of the

seat, using the Push/Pull tool. Push the rectan-

gle ¾″ into the seat edge. The resulting slot

should be 4″ × ¾″ × ¾″.

16D: Create an identical slot on the opposite

end of the seat.

16E: Create 4″ × ¾″ slots on front and back

seat edges. Exit the component, and using

guidelines, locate two vertical construction

lines at the middle of the front edge. Cut and

paste the construction lines into the compo-

nent.

16F: Push a 4″ × ¾″ × ¾″ slot into the front

edge, using the Push/Pull tool. Repeat these

steps to create an identical slot on the back

edge of the seat.

16G: Double-check length and width with the

Measure tool. It’s especially important that

your perimeter slot width aligns with the ¾″

thickness of the adjacent part.

faces align, and that you modeled the length

and width precisely.

16H: Create two horizontal construction lines

in the seat center. Exit the component and

draw using the guidelines and the beam as your

reference. These construction lines will be ¾″

tall and 4″ apart, as seen on the right in

Figure 4-19. Cut and paste the construction

lines back into the component.

16I: Make the center slot in the seat, using the

Push/Pull tool to push the 4″ × ¾″ rectangle all

the way through the seat.

16J: Exit the seat component.

Measure as you go, after making slots (and

tabs). Use the measure tool to check that

04/GETTING STARTED WITH DESIGN

111