MAKE JOINERY

MAKE JOINERY

This next section walks you through the pro-

cess of modeling the joinery, by using the refer-

ence lines you just drew. Going part by part,

you’ll get started on making a corner assembly,

and what will eventually become a tab assem-

bly. You’ll start with the simple task of adding

slots in the seat, and follow up by modeling

both slots and tabs in the front, back, and side

parts. The section will then walk you through

the slightly more complex task of modeling a

hanger assembly and foot assembly, which

involve joining together three parts.

construction lines help you accurately form the

surfaces from which you use SketchUp’s Push/

Pull tool to shape the slots.

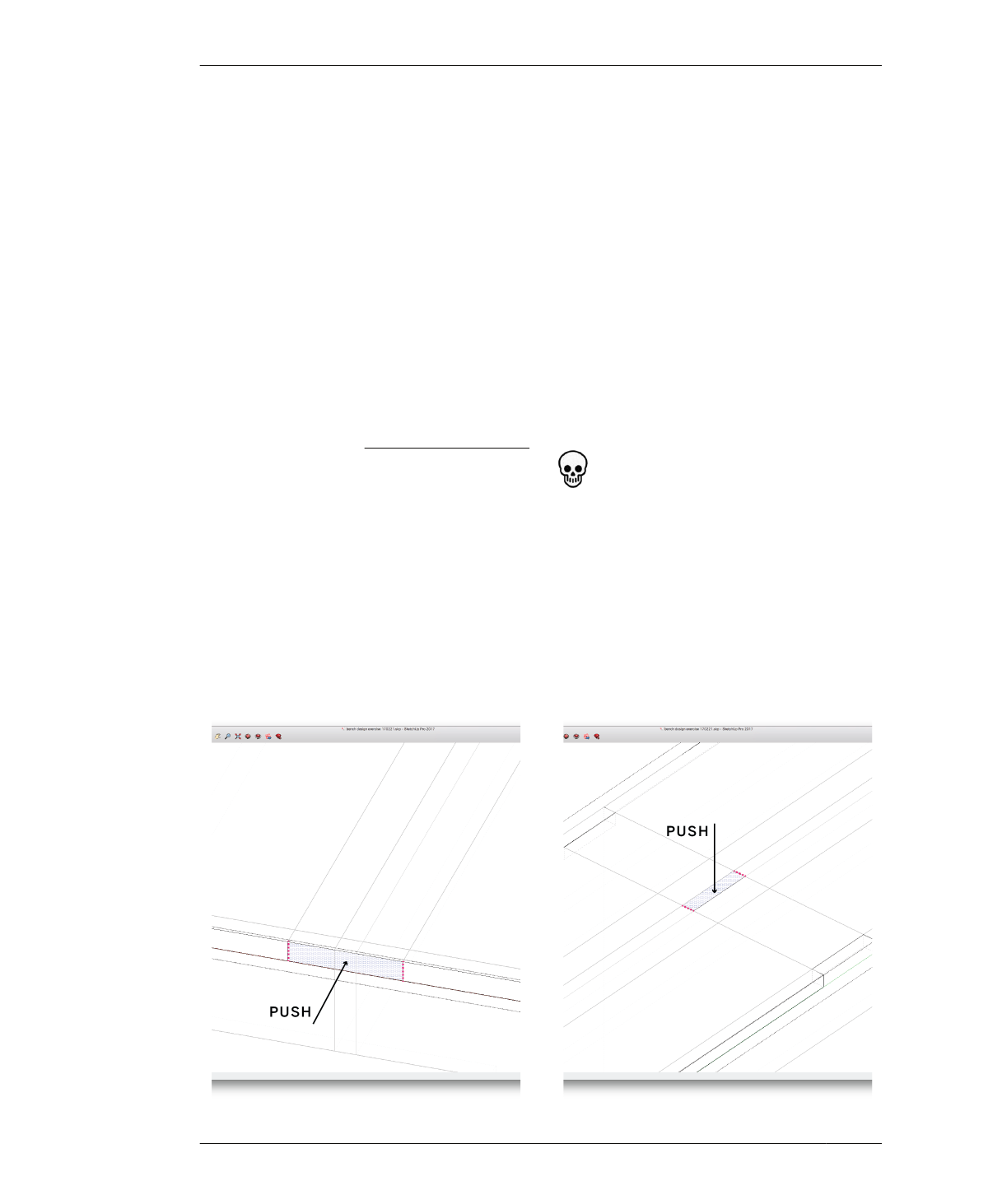

16A: Draw two vertical construction lines at

one end of the seat, by using the guidelines as a

reference. Each construction line should be ¾″

(19 mm) tall and spaced 4″ (100 mm) apart.

See the left-hand side illustration in Figure 4-19.

Select all construction lines and go to Edit→Cut.

16B: Fully select the seat component three

mouse clicks are required to select and edit the

component, and Edit→Paste the construction

lines into it.

CREATE SEAT SLOTS

The seat has five slots. You’ll first model its four

perimeter slots, each at the midpoint. Then

you’ll start on the tab assembly by modeling a

fifth slot centered exactly in the middle of the

seat.

To form each perimeter slot, you’ll start by

drawing small, precise construction lines out-

side the component, by snapping to the guide-

lines and to the model parts themselves. These

Always draw construction lines outside of the

component; then cut and paste them into the

component when it’s selected for editing.

Drawing construction lines directly inside the

component can cause the lines to interfere

with geometries. This process of drawing, cut-

ting, editing, and pasting becomes automatic

after you do it a few times.

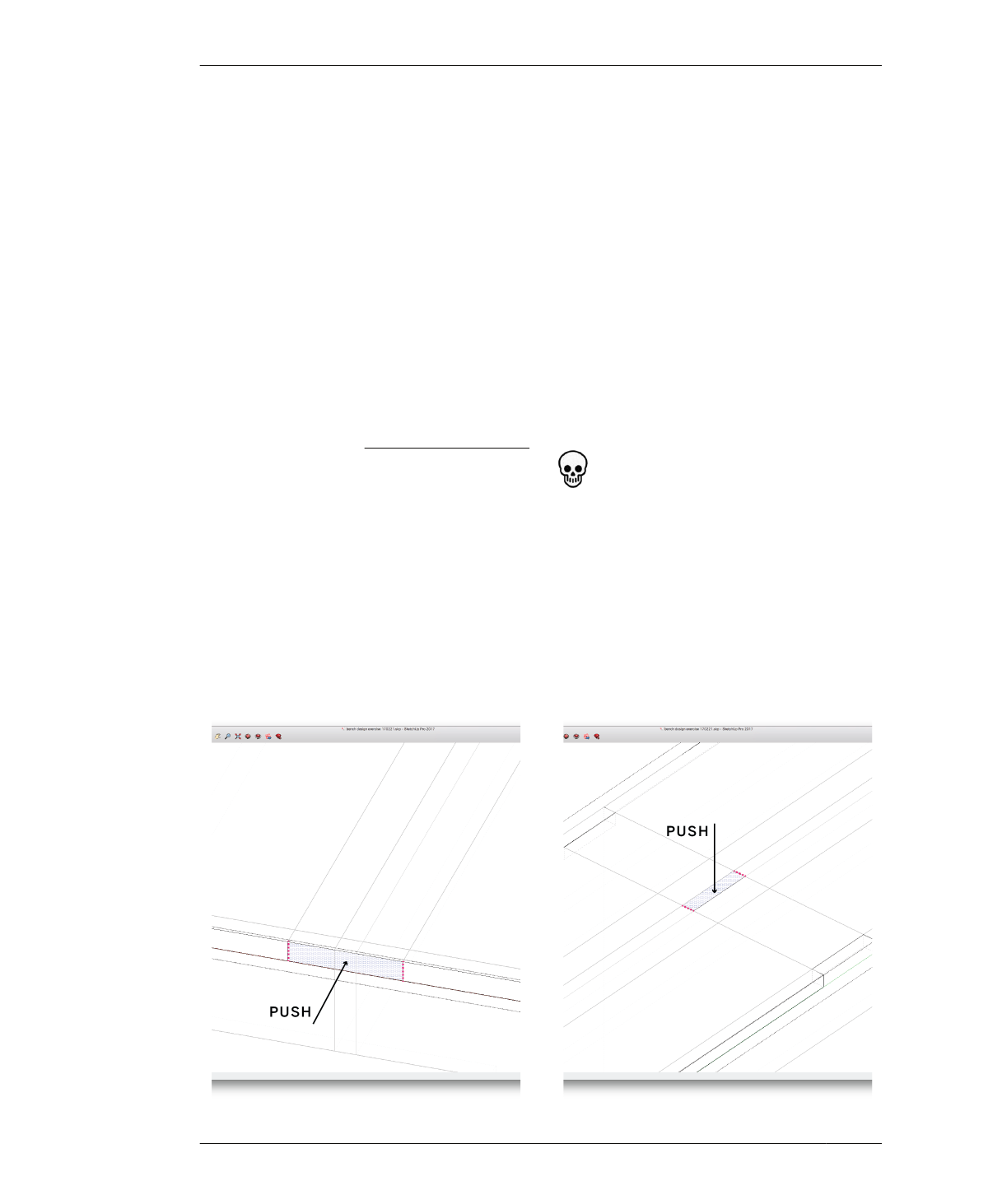

FIGURE 4-19

Push slots into the

sides and top of seat

110

DESIGN FOR CNC