- You are here:

- AM.CO.ZABuythisCNC Utilities Homepage

- PowerRoute-CNC-Router

- Mill Programming Manual.pdf

- Page 98 of 151

1. G Function Description

Description:

1. use G00 to move tool to specified (X, Y) point, when performance

start

2. use G00 reach the specified R point(not include spindle

positioning)

3. use G01 reach point Z at the bottom of the hole, dwell P(s) and

spindle positioning and stop the drill

4. shift Q distance

5. use G00 raise to initial point (G98) or programmable point R

(G99)

6. shift Q distance in reverse direction

7. drill start

※ alarm:

Q is a Modal Value that requests in G76 cycle, we must specify

this Q value carefully, because it also use in G73/G83.

OSS(Oriented Spindle Stop) direction is decided by parameter No.

4020:

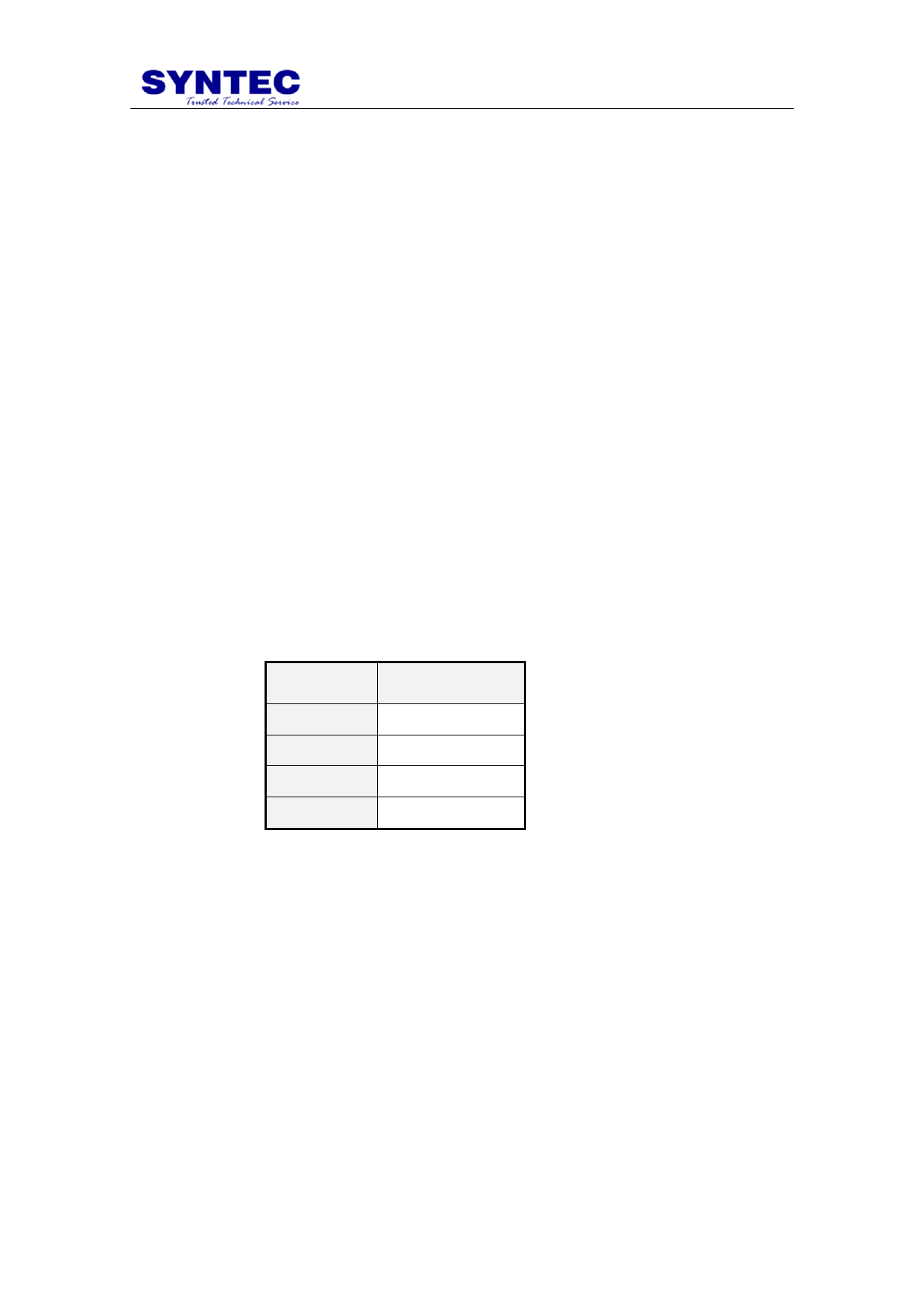

Parameter

4020

0

OSS direction

+X

1

-X

2

+Y

3

-Y

Note:

1. before G76, use M Code let drill start to rotate CW.

2. if M Code and G76 are specified in the same block ,this M Code

only executes in the first time of positioning in that block

3. when K is used to specify numbers of times, this M Code is

executed for the first only, for the second hole and subsequent

holes, the M Code is not executed.

4. G76 is module G Code ,it is always effective when we use

once ,we only specify (X,Y) in next line of program ,controller

will execute drilling at (X,Y)

93