- You are here:

- AM.CO.ZABuythisCNC Utilities Homepage

- PowerRoute-CNC-Router

- Mill Programming Manual.pdf

- Page 77 of 151

1. G Function Description

1.2.27 G64: CUTTING MODE

Command form:

G61 ; // exact-stop examination mode

G62 ; // curved surface cutting mode

G63 ; // tapping mode

G64 ; // curved surface cutting mode

G64;

Description:

G64 is similar to G09, G61 in usage, NC use smooth cutting face mode

to cut. This mode does not decelerate and stop between G61 and reverse

cutting feed block, the mode will continue to execute next block. G64 can

be canceled by G61, G62, G63.

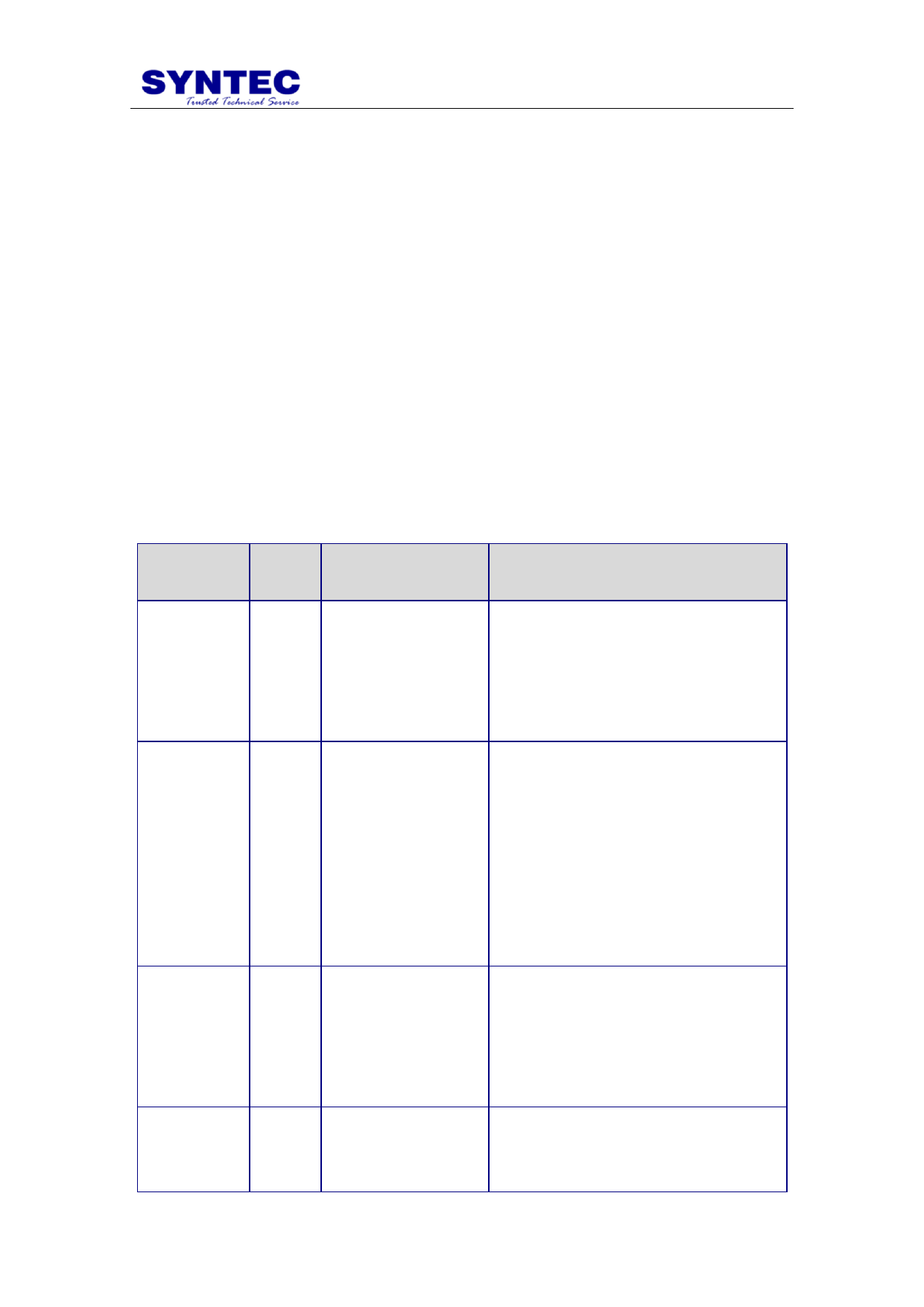

Command

name

Exact stop

Exact stop

G code range

description

When tool decelerates at the end of

path, The precision error occurs at the

Only effective in

G09

corner when the tool direction turns.

block with G09.

G09 is used to control the precision

error.

G61 is similar to G09. The difference

is G61 effective until we set G62, G63,

or G64. Tool decelerates at the end of

G61 is effective until

corner. When tool arrived at the

G61 we set G62, G63,

terminal, a feedback signal is sent to

G64.

ensure the position is in the setting

range. The next path is executed after

the feedback control.

Applicable to curved surface cutting.

G62 is effective until Tool does not decelerate at the end of

G62 we set G61, G63, or path (refer to the speed command

G64.

curve shown below) and continue

execute next path.

G63 is effective until Applicable to tapping. To synchronize

G63 we set G61, G62, or spindle and feed axis. The relation

G64.

between spindle and feed axis is

72