- You are here:

- AM.CO.ZABuythisCNC Utilities Homepage

- PowerRoute-CNC-Router

- Mill Programming Manual.pdf

- Page 70 of 151

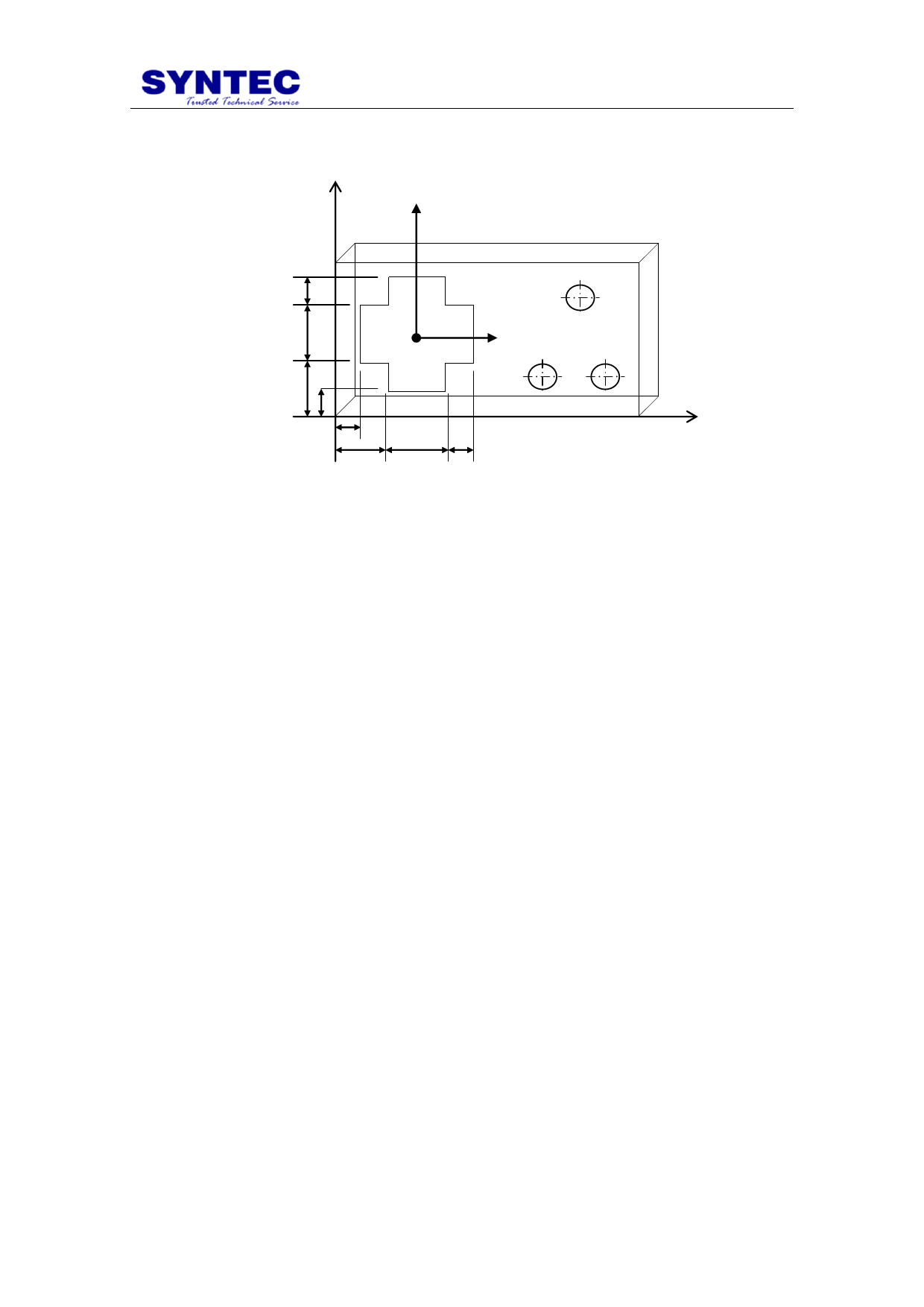

Example:

1. G Function Description

Y

10

20

20

10

10

G54 20

G

52

20 10

3rd hole

thickness10mm

1st hole

(100, 65)

2nd hole

(90,15)

(110, 15)

X

Program description:

N001 T1 S1000 M03;//tool No.1(diameter 10mm), spindle 1000rpm

(CW)

N002 G54 X0.0 Y0.0 Z0.0;//specify work coordinate (G54)

N003 G00 X90.0 Y15.0 Z10.0;//positioning to above of specified

position

N004 G43 H01;//tool length compensation (tool No.1)

N005 G99 G81 Z-15.0 R2.0 F1000;//execute drilling cycle, stop at R

point when return, feedrate 1000mm/min, drill 1st hole

N006 X110.0;//drill 2nd hole

N007 X100.0 Y65.0;//drill 3rd hole

N008 G80;//cancel cycle

N009 M05;//spindle stops

N010 G28 X0.0 Y0.0 Z10.0;//reference point return, X0.0,Y0.0,Z10.0

to be center point

N011 T2 M06 S1000 M03;//execute tool exchange(tool No.2 diameter

10mm), after finishing, spindle start to turn, 1000rpm(CW)

N012 G52 X30.0 Y30.0 Z0.0;//specify local coordinate zero point to

the work coordinate (G54) of X40.0,Y40.0,Z0.0(geometry center of

workpiece)

N013 G00 X0.0 Y0.0 Z10.0 ; //positioning to local coordinate

X0.0,Y0.0,Z10.0(above the hole)

N014 G01 Z-12.0;//linear interpolation to bottom of the hole

65