- You are here:

- AM.CO.ZABuythisCNC Utilities Homepage

- PowerRoute-CNC-Router

- Mill Programming Manual.pdf

- Page 7 of 151

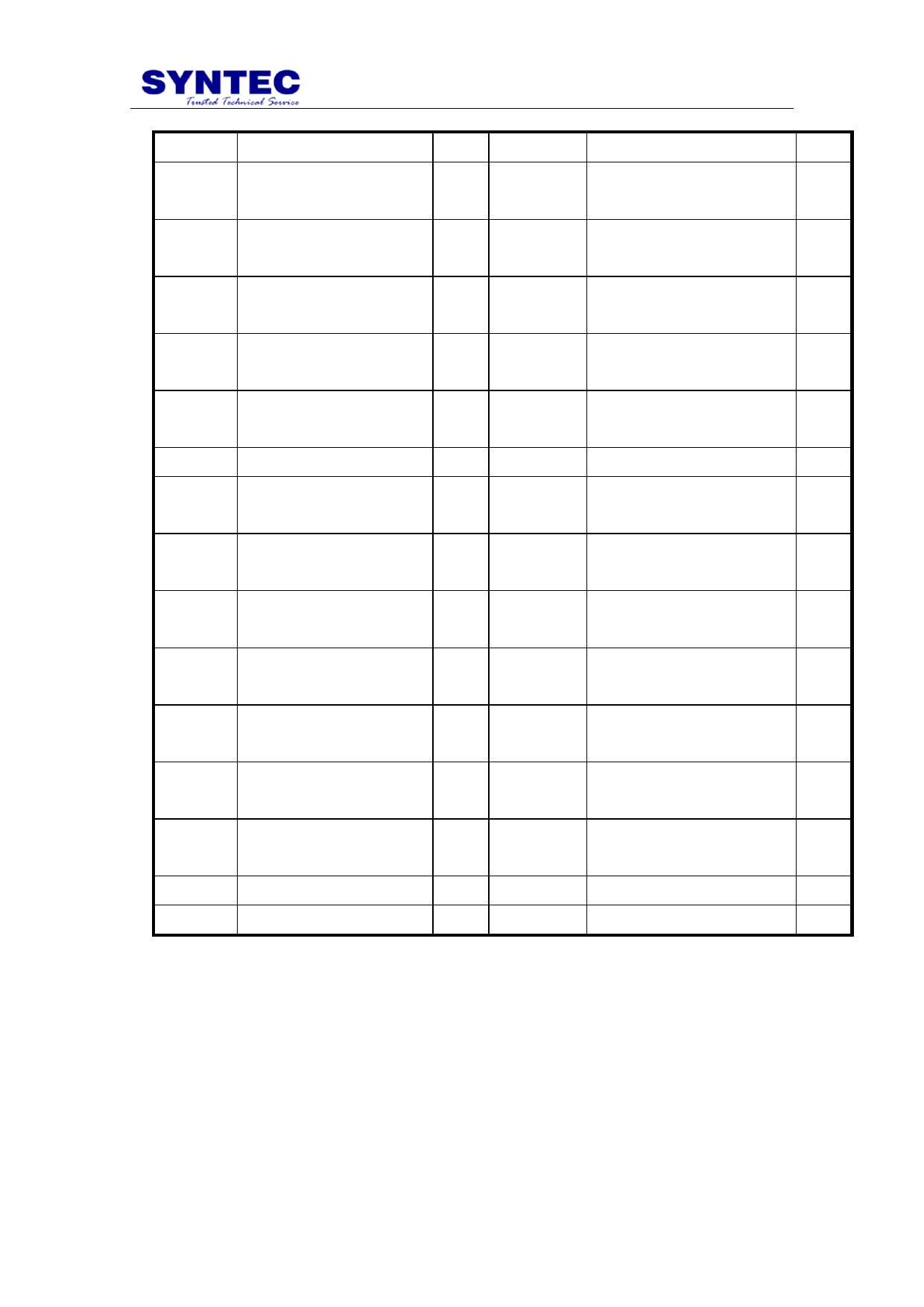

1. G Function Description

G41

G42

G43

G44

G49

G50

G51

G50.1

G51.1

G52

G53

G54

G59

G61

cancel

Cutter compensation left

Cutter compensation

right

Tool length

compensation + direction

Tool length

compensation - direction

Tool length

compensation cancel

Scaling

Scaling cancel

Programmable mirror

image cancel

Programmable mirror

image

Local coordinate system

setting

Machine coordinate

system setting

Workpiece coordinate

system 1 selection

Workpiece coordinate

system 6 selection

Exact stop mode

side

Fine boring cycle of half

G88

automation

Boring cycle of dwell on

G89

the hole bottom

G90

Absolute command

G91

G92

G94

G95

G96

G97

G98

G99

G134

Increment command

Setting of work coordinate

system

Feed per minute(mm/min.)

Feed per rotation

(mm/rev.)

Constant linear velocity

control on surface

Constant linear velocity

control on surface cancel

Return to initial point in

canned cycle

Return to R point in

canned cycle

Circumference hole cycle

G135

G136

G137.1

Angular straight hole cycle

Arc type hole cycle

Chess type hole cycle

SYNTEC 900M G code uses RS274D standards, and the only

differences with FANUC 0M are G70, G71 respective to G20,

G21.

2