- You are here:

- AM.CO.ZABuythisCNC Utilities Homepage

- PowerRoute-CNC-Router

- Mill Programming Manual.pdf

- Page 137 of 151

1. G Function Description

1.2.49 G134: CIRCUMFERENCE HOLE CYCLE

Command form:

G134 X Y I J K ;

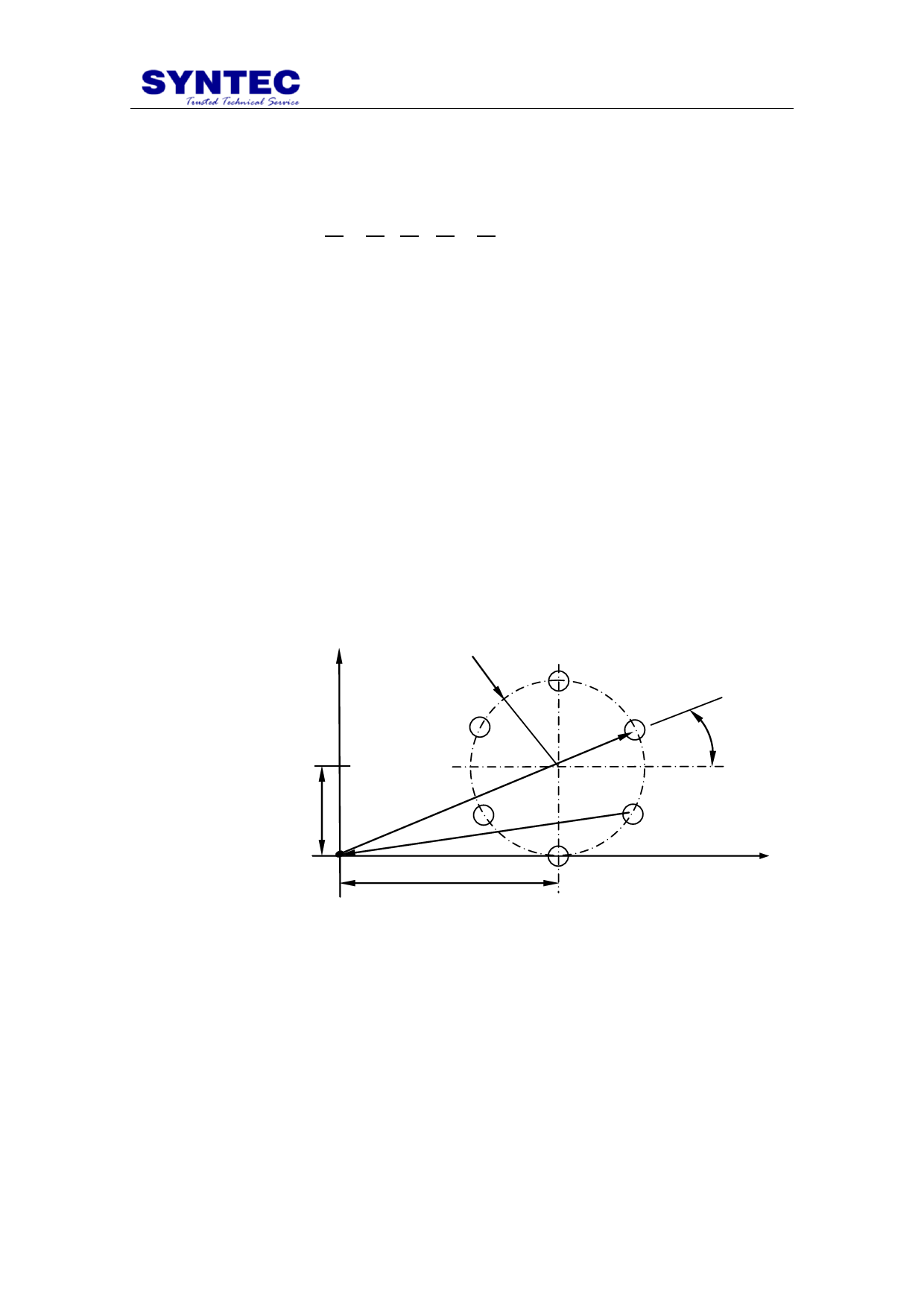

X, Y: center position of circumference hole, effective by G90/G91.

I: radius of circle(r), unit is specified by G70/G71, must in positive

value.

J: angle of initial drilling hole.

K: number of holes. Range 1~9999, can not be zero. It is specified

positive when CCW, negative when CW.

Description:

Use the point between X axis and angle ,start to make the circle in n

parts, n holes. The point is on the circle that center is specified (X,Y) and

the radius is r.

Example:

r =100 mm

Y=100 mm

X=200 mm

20∘

Program description:

G92 X500.0 Y100.0;//set absolute zero point coordinate system

G91 G81 Z-10.0 R5.0 K0 F200;

//execute drilling cycle, feedrate 200mm/min, depth 10 mm, and return

to initial point when finish

G134 X200.0 Y100.0 I100.0 J20.0 K6;

//execute circumference hole cycle, X=200mm,Y=100mm drill the first

hole, radius 100mm, starting angle 20∘, 6 holes

G80;//cancel cycle

132