Shanghai Fangling Computer Software Co., LTD.

Tel: 021-34290970 Website: www.flcnc.com

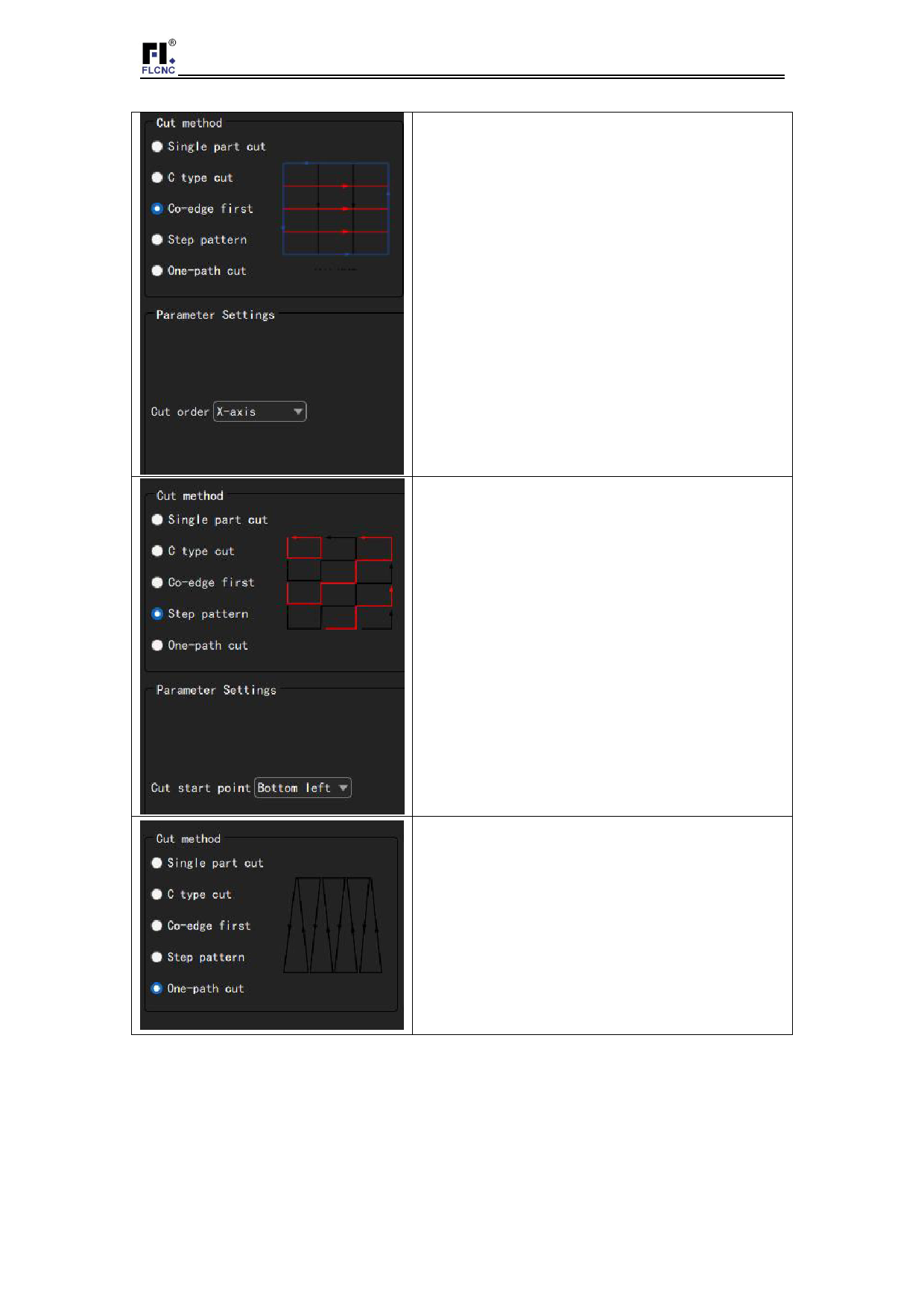

Shared borders take precedence

First, cut the common edge of the part, and then

cut the outer frame. This common edge method

is usually suitable for the processing of more

regular rectangular parts, which can quickly

process straight strips and reduce the number of

perforations.

In the common edge type with common edge

priority, a notch process can be introduced to

reduce the collision phenomenon caused by

thermal deformation.

The trapezoids share a side

The cutting path adopts trapezoidal trajectory,

which is mainly suitable for the machining of

thick plate rectangular parts. This method can

effectively prevent edge lifting, reduce the

number of empty walking and perforation, and

improve the machining efficiency.

One stroke of cutting

For some graphics, a "one size fits all" path

planning can be implemented to reduce empty

walking and perforation.

For thicker plates, it is usually necessary to add a cut compensation. After the

compensation of parts that need to be shared, the shared operation is performed. If the

shared graphics already contain compensation, the trajectory after compensation will

be retained after the "shared" operation is completed.

Note: Common edge material is only suitable for parts with more right angles for

38