Shanghai Fangling Computer Software Co., LTD.

Tel: 021-34290970 Website: www.flcnc.com

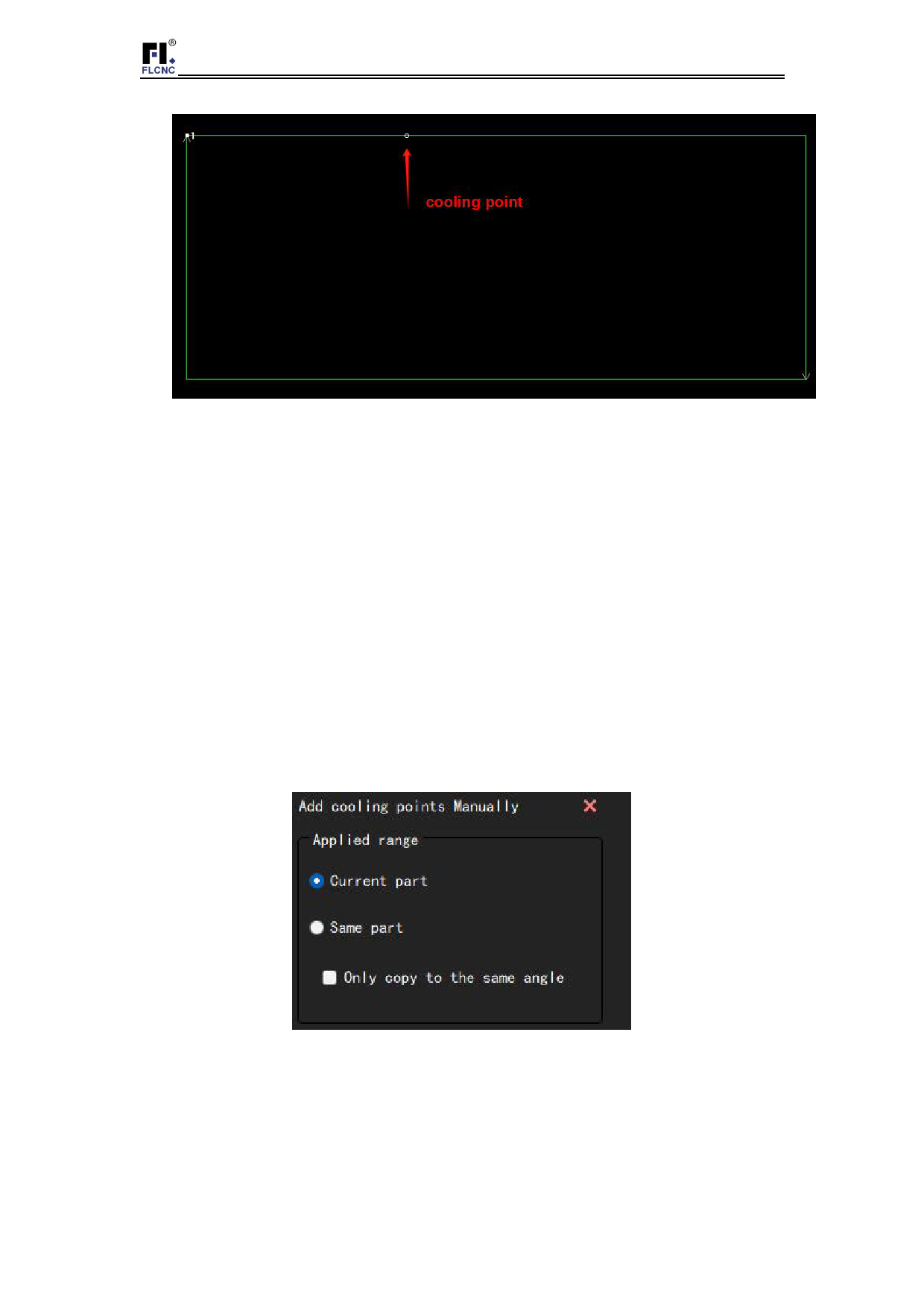

The "cooling point" function refers to the process of cutting, when the cooling

point is executed, the laser will be turned off, and the delay blowing will be carried

out according to the relevant setting of the cooling point in the global parameters, and

then the laser will be turned on to continue normal cutting.

Cooling points are usually used in corner processes, where a pause is made at the

corner, the laser is turned off and blown to prevent the material from burning.

Similar to the micro-link function, multiple cooling points can also be inserted by

clicking continuously. Cooling points can still be added after performing processes

such as micro-link and compensation.

When cutting thick plates with oxygen, the reasonable setting of cooling point can

effectively reduce the overheating phenomenon of sharp corners.

Automatic cooling point: Add parts that need to be added to the cooling point in

batches according to the set parameter value. Yes

Add at the starting point and the corner.

Manual cooling point: Select the position where you want to add a cooling point

on the part graphic and click to set a cooling point at this position.

Note: When setting the starting point in the discharge area, you can set the

cooling points for all identical parts that have been laid out in batches.

10.Flick

"Flight cutting" is applied to the processing of regular graphics (circle, square)

array, using the optimal processing path specification

It can greatly improve the processing efficiency and reduce the processing time. The

32