YDFLP-CL2-200-1/5-A&YDFLP-CL2-300-1/5-A User Manual

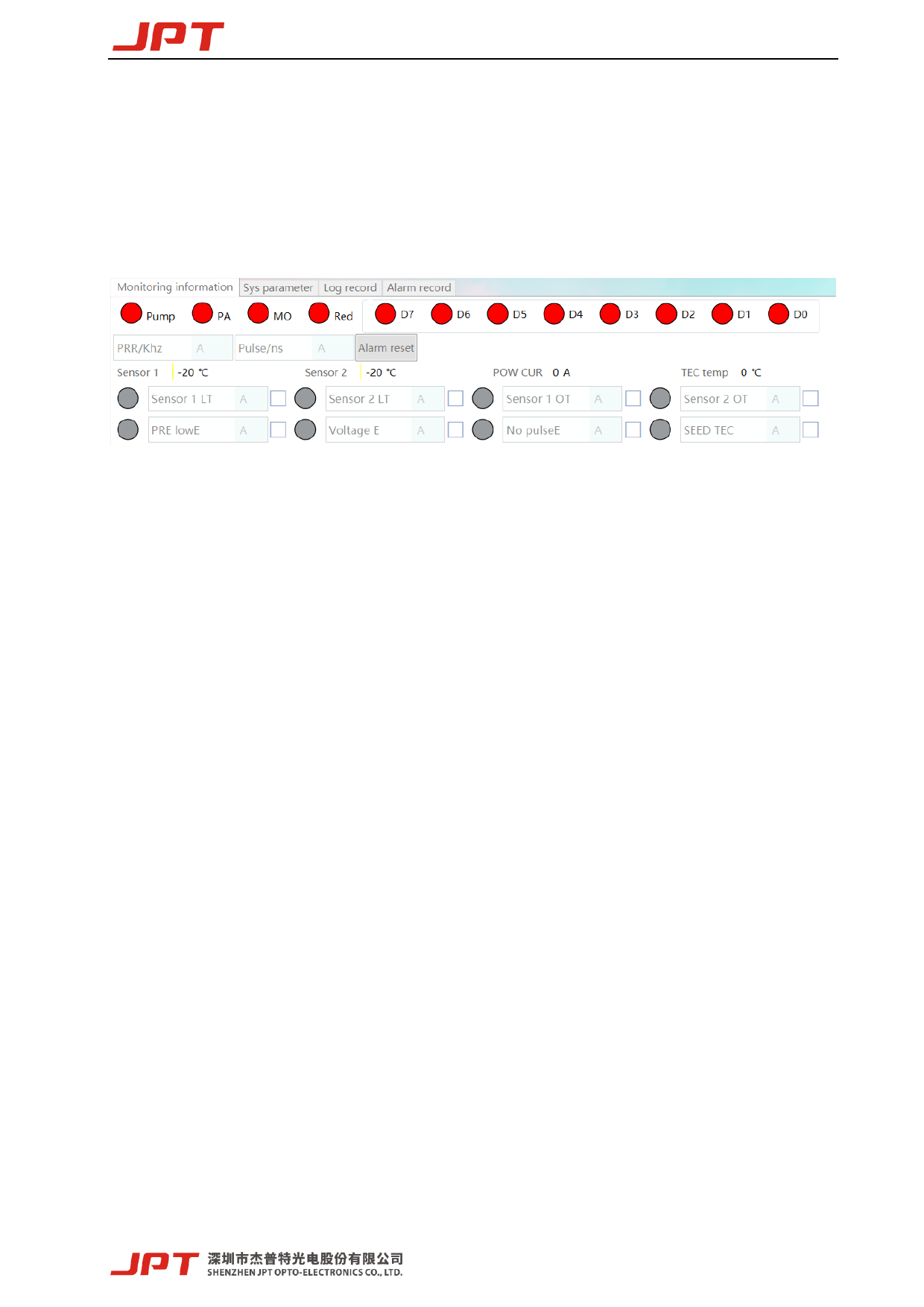

3.3 Laser Monitoring Function

The monitoring function of TypeE software can observe some operation parameters and

alarm conditions. The laser will send the number of alarms saved in the system to the GUI

software each time when it is turned on.

Figure 21. Laser Running Status Monitoring

1) Status Monitoring

Pump: monitors whether the laser pump is in normal working condition. It is green under

normal conditions, and it will be red in case of abnormal alarm.

PA, MO and Red: monitor whether the laser currently receives the control signal. The

green light is the status of received signal, and the red light is the status of not received signal.

D7-D0: monitor the current power signal of the laser, corresponding to the 8-bit binary

mode. D0 is the lowest bit, D7 is the highest bit, and the green light is the status of the received

signal of this bit.

Pulse width: monitor the working pulse width parameter of the current laser.

Frequency: monitor the current laser operating frequency parameter.

Sensor 1: monitors the temperature of the optical path module of the current laser.

Sensor 2: monitors the current output isolator temperature.

POW CUR: monitors the working power of a group of pump sources inside the current

laser.

TEC temp: monitor the current laser seed source TEC temperature

23