YDFLP-CL2-200-1/5-A&YDFLP-CL2-300-1/5-A User Manual

➢ A: 12 seconds System initialization time

➢ B: MO and PA signal delay time: range(8ms-35ms), recommend 8ms.

➢ C: Switching off PA should be earlier than MO or at the same time.

➢ D: Frequency sampling time under internal frequency mode, at least 1 complete frequency

period before turning on the laser (PA).

➢ E: SIMMER value. The first pulse energy can be adjusted via GUI software.

Fiber laser control system self-locking:

If fiber laser is on abnormal status (high temperature, low power supply etc.), it will stop

working to protect the whole system. Please restart the fiber laser.

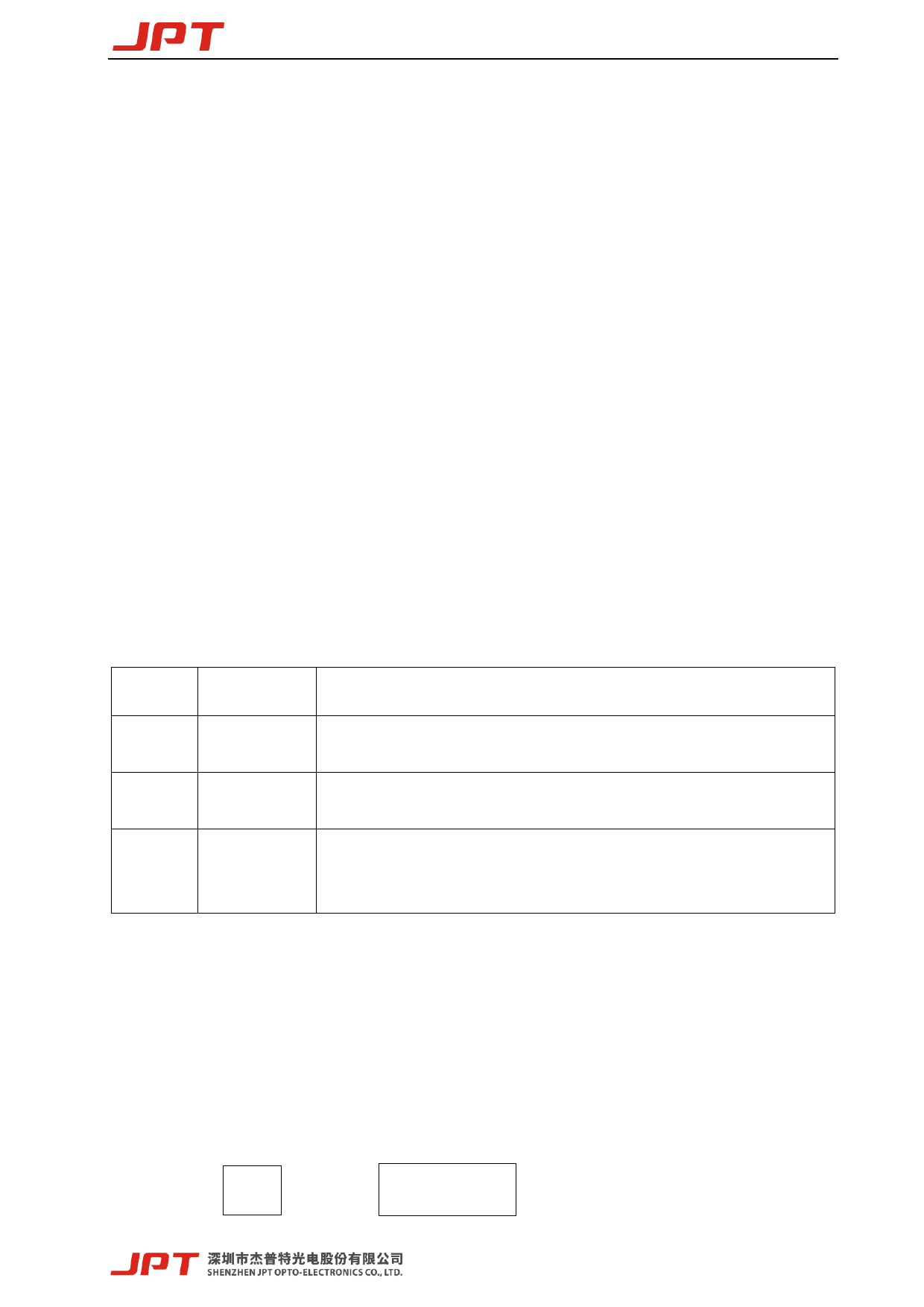

Pulse Width Control

PIN2, PIN3 and PIN22 pins of DB25 control interface are not only used for basic control of

laser, but also for pulse width control. Table 10 shows the pulse width control pin and signal

description of laser.

Table 10. Pulse Width Control Pin and Signal Description of CL Series Laser

PIN. #

2

3

22

Item

Description

Serial Input

Serial Clock

Enable

When fiber laser is serial input, setting data bits synchronize with

the rising edge of serial clock.

Serial digital clock, 8kHz≦Clock Frequency≦10kHz, 10KHZ is

recommended.

Pulse width control function:

High: Enable, Pin2 and Pin3 to control the pulse width

Low or Not connection: Disable

1) Pulse Width Control Instruction Structure

➢ Send instruction to Pin2 of DB25 connector and send clock signal to Pin3 at the same

time. The instruction description will be transmitted in binary form, with its most significant

bit transmitted first.

➢ The instruction structure transmitted by the user to the laser is as follows:

0xA

Instruction

5

Code

13