BM109 SERIES 1.5KW Auto-Focusing Laser Cutting Heads

better the quality of the cutting section.

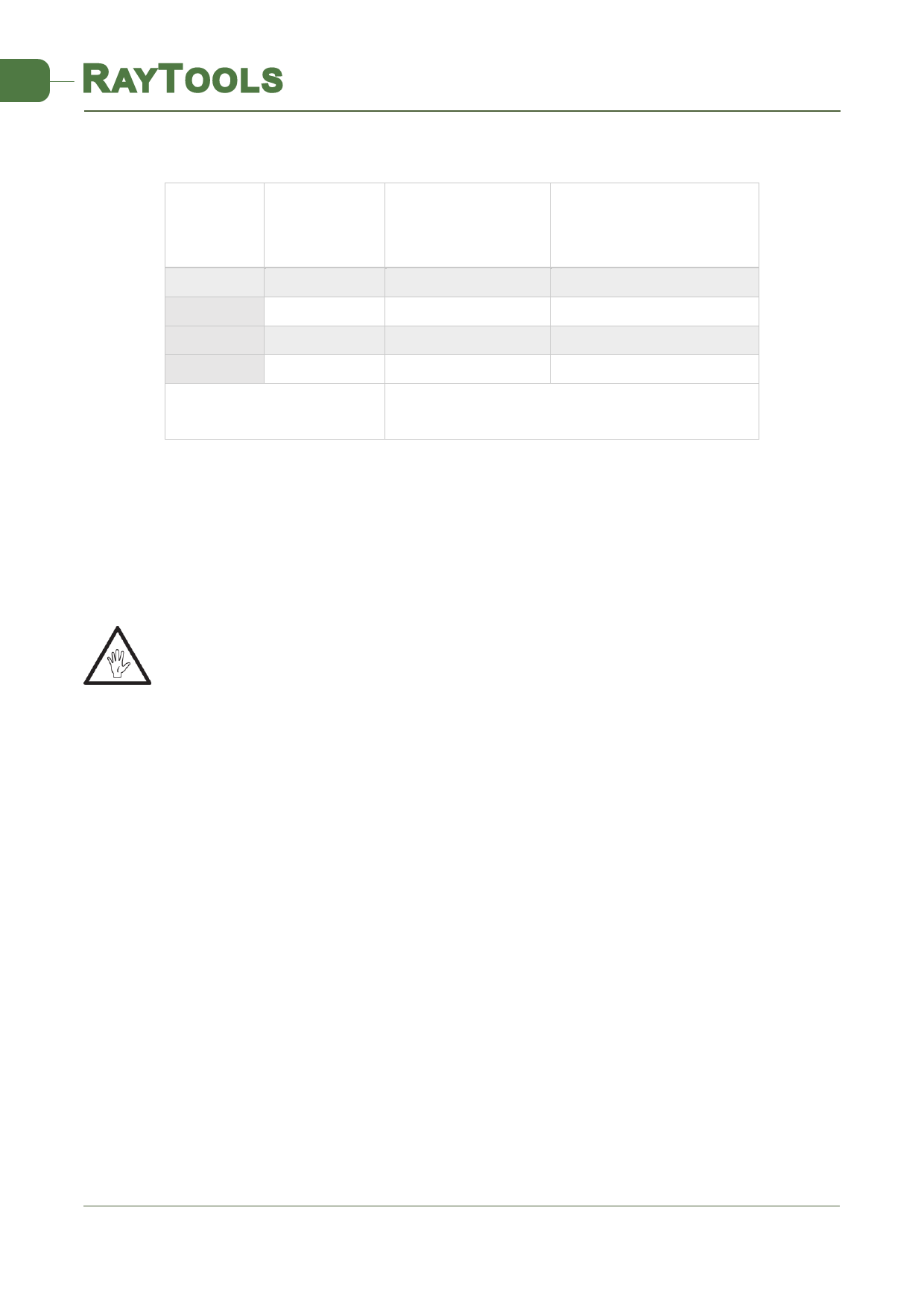

Gas

Purity

oxygen

99.95%

nitrogen

99.99%

argon

99.998%

helium

99.998%

Diameter of cooled gas

pipe (Outer diameter)

Maximum content

of water vapor

(ppm)

<5 ppm

<5 ppm

<5 ppm

<5 ppm

Maximum content of

hydrocarbon(ppm)

<1 ppm

<1 ppm

<1 ppm

<1 ppm

10mm

Impurity can be filtered out in gas supply tube, but oxygen and water vapor can permeate

the light path system through nonmetal materials, which is the source of the appearance of dust

and hydrocarbon. Stainless steel fittings are recommended, at the same time, operators must

use filters which can remove a minimum of 0.01 micron particle to purify.

A pressure gauge with a stainless steel diaphragm is recommended. Industrial pressure

gauges suck in air. Rubber diaphragm produce hydrocarbon by aging or other factors.

CAUTION: gas interface can not be replaced arbitrarily, especially do not use PTFE TAPE,

Otherwise, the gas path will be blocked, the normal cutting will not be possible and the laser

head parts will be damaged at the same time.

2.3 Connection of Cutting Head Cable

This paper mainly introduces the connection between the cable and the cutting head. The

connection of control sections such as the driver refers to the wiring diagram of each series of

system.

2.3.1 Connection of Cutting Head and Cable

Connect the corresponding connector of cutting head with eight-core power limit cable,

twelve-core encoder cable respectively (as shown in Figure 3.3). After the proper length is

reserved, insert and fix the cable into the track groove of the machine tool.

V1.0

RayTools AG © Copy Right

8 | 24

www.raytools.net