BM109 SERIES 1.5KW Auto-Focusing Laser Cutting Heads

Remove the gland of collimating protective lens, pinch the two sides of the drawer-type lens holder

and pull out the base of protective lens; seal the part connected with the components of collimating

protective lens with textured paper so as to prevent the entry of dust;

Wear the fingerstall and take out the lens;

Clean the lenses, lens holder and seal rings, and replace a new one for the damaged elastic seal ring;

Install the new lens (regardless of the front and back sides) wiped clean into the drawer-type lens

holder;

Re-install it back to the seal ring;

Re-insert the collimating protective lens holder to the laser processing head, cover the lid of

collimating protective lens and tighten the locking screw.

Note: It is not allowed to directly pull out of the edge of the elastic seal ring, which will damage the elastic

Elastic seal ring

protective lens

collimation protective lens holder

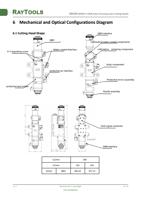

Figure 6.3 - Take out collimation protective lens

seal ring very easily.

Figure 6.4 - collimation structure of protective lens

5.2.3 Removal and Installation of Collimating Lenses

Removal and installation of collimating lenses refer to the following steps:

Remove the laser head, move it to a clean place, and clean all dust on the laser head surface;

Use a 3mm internal hexagonal wrench to unscrew the locking screws of the collimating

components (as shown in Figure 6.5), seal the part connected with the components of collimating

components with textured paper so as to prevent the entry of dust;

Screw out the collimating lens holder, and remove the spring compression ring and collimator

lens with the lens-removing tools;

Replace or clean the collimating lenses.

As shown in Figure 6.6, reassemble the components of collimating lens in order, pay attention to

V1.0

RayTools AG © Copy Right

18 | 24

www.raytools.net