BM109 SERIES 1.5KW Auto-Focusing Laser Cutting Heads

2 Machinery Installation

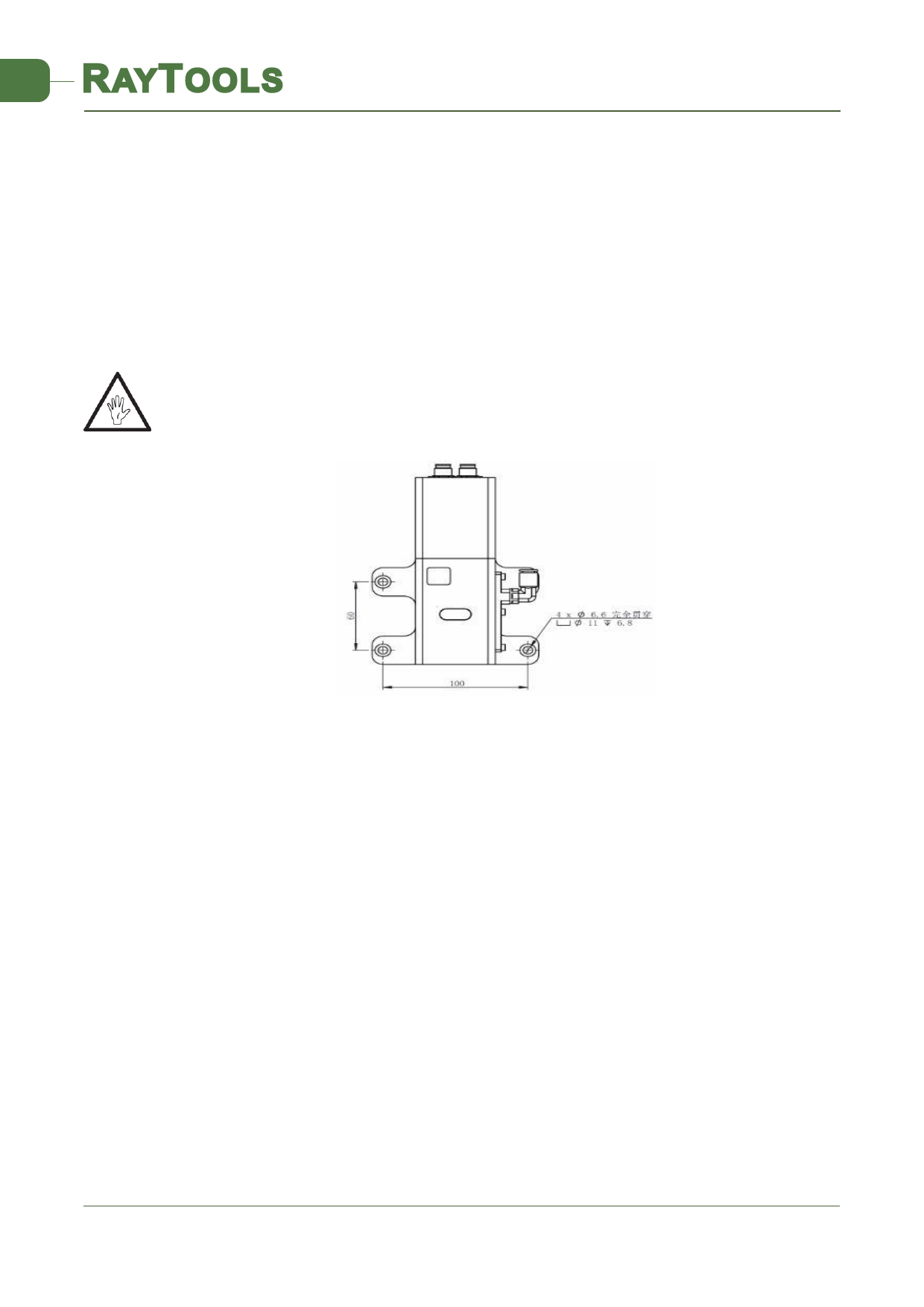

2.1 Hole Site installation

BM109 laser machining head and the fixed mounting hole size and position of the machine

tool are shown in Figure 3.1. Customers are advised to install the laser head perpendicular to

the machined surface as requested and make sure the laser head is locked, which is one of the

premises to ensure the follow up sable cutting effect.

CAUTION: the Z-axis sliding base for fixing laser processing head should be connected with

machine tools and keep a good grounded.

Figure 3.1 - Hole site installation

2.2 Connection of Water Pipe and Gas Pipe

2.2.1 Water-cooled Interface

BM109 laser processing head has 2 sets of water-cooled channels which direction of water

entry and exit can be arranged arbitrarily. It is important to note that when the laser power is

greater than 500 watt hours, it is recommended to use water-cooling. As you can see from Figure

3.2, the position and amount of the water-cooled interface, and the right table details the

recommended flow velocity.

V1.0

RayTools AG © Copy Right

6 | 24

www.raytools.net