BM109 SERIES 1.5KW Auto-Focusing Laser Cutting Heads

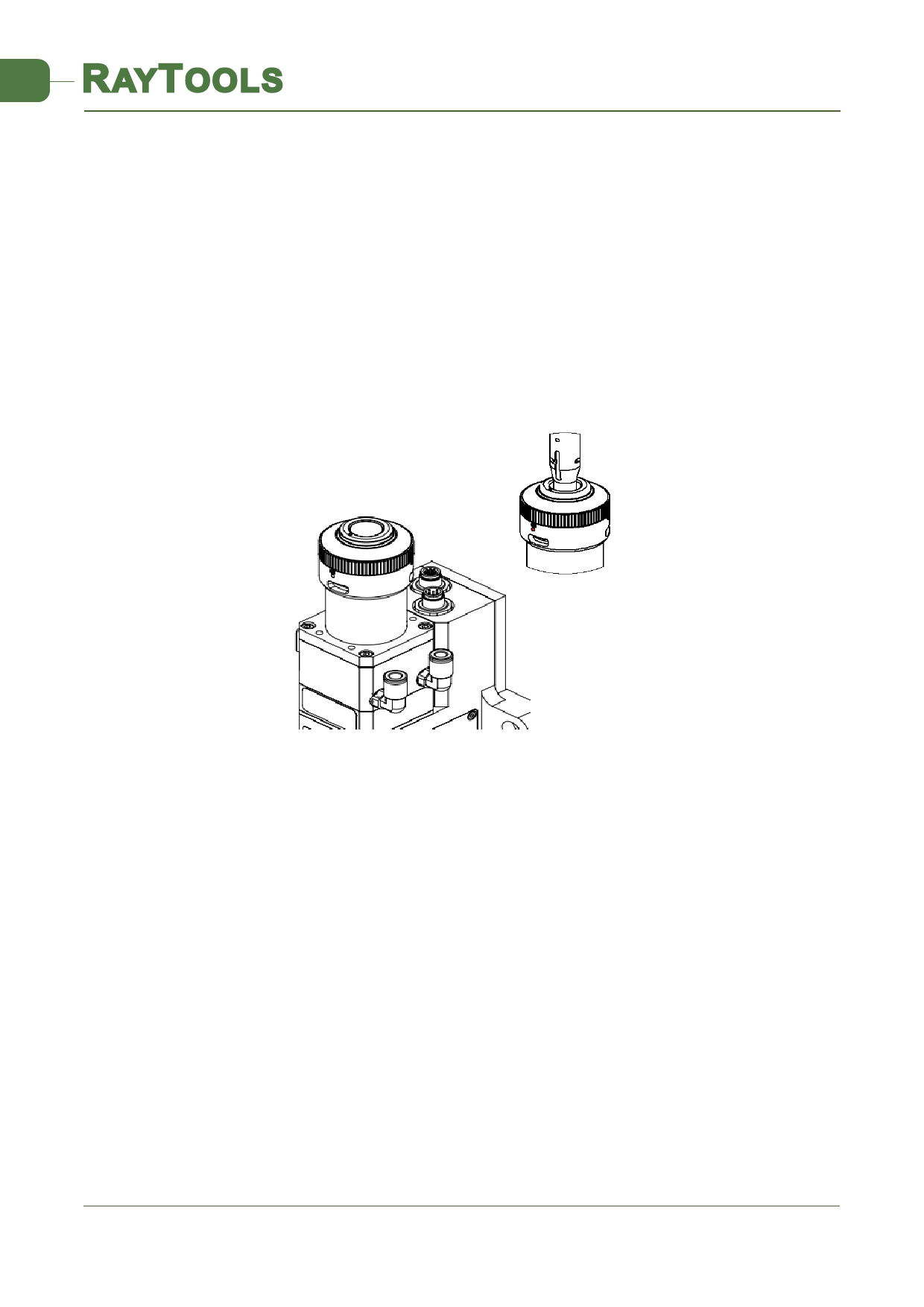

In this paper, an optical fiber insertion method is described in conjunction with a QBH joint.

First, align the red point at the end of the QBH interface with the red point of the handwheel;

then remove QBH dust proof cover and align the red mark of fiber output end with QBH red

mark and insert straight lines to bottom; then turn the QBH handwheel clockwise. It is in place

when you hear the "Da" sound, then pull the handwheel up and turn clockwise again. (see Figure

3.4)

When the fiber connector is inserted into the interface, the red dot on fiber is too far away

from the red dot on laser head interface, causing alignment insertion impossible, and at this time,

the user can refer to steps below to adjust the position of fiber interface on laser head for solving

the problem. As shown in Figure 3.4, unscrew the 4 locking screws of the graphical position of

the part with a wrench, rotate the QBH interface and screw the locking screws after the red mark

is in place.

Figure 3.4 - Diagram of inserting fiber into QBH interface

V1.0

RayTools AG © Copy Right

10 | 24

www.raytools.net